The requirements for logistics software have changed significantly in recent years. Shipping is no longer an isolated step at the end of a value chain, but an integral part of complex processes. Anyone who moves goods today must generate, process and reliably pass on data. It is precisely in this area of tension between software, hardware and operational practice that Heidler positions itself as a provider of holistic solutions for the logistics sector.

The company has grown as a family business and can look back on a long history of development. Founded in the early 1990s, Heidler has continuously evolved in line with the practical needs of shippers, logistics service providers and industrial companies. With the generational change in management, this course has been continued and expanded in terms of content. The focus remains clearly on software, supplemented by products that are needed in daily logistics operations.

The structure as a family business has a noticeable impact on the company's orientation. Decisions are not made in the short term, but are based on long-term developments in the logistics market. The team is relatively small, but highly specialised. The focus is on the development of software solutions, particularly in the shipping environment, supplemented by systems for data collection and process support. This combination is no coincidence. Shipping software only fully demonstrates its benefits if the underlying data is correct. Dimensions, weights and unique identifications form the basis for price calculations, transit times and the selection of suitable transport service providers. Heidler therefore deliberately focuses on the close integration of software and data collection.

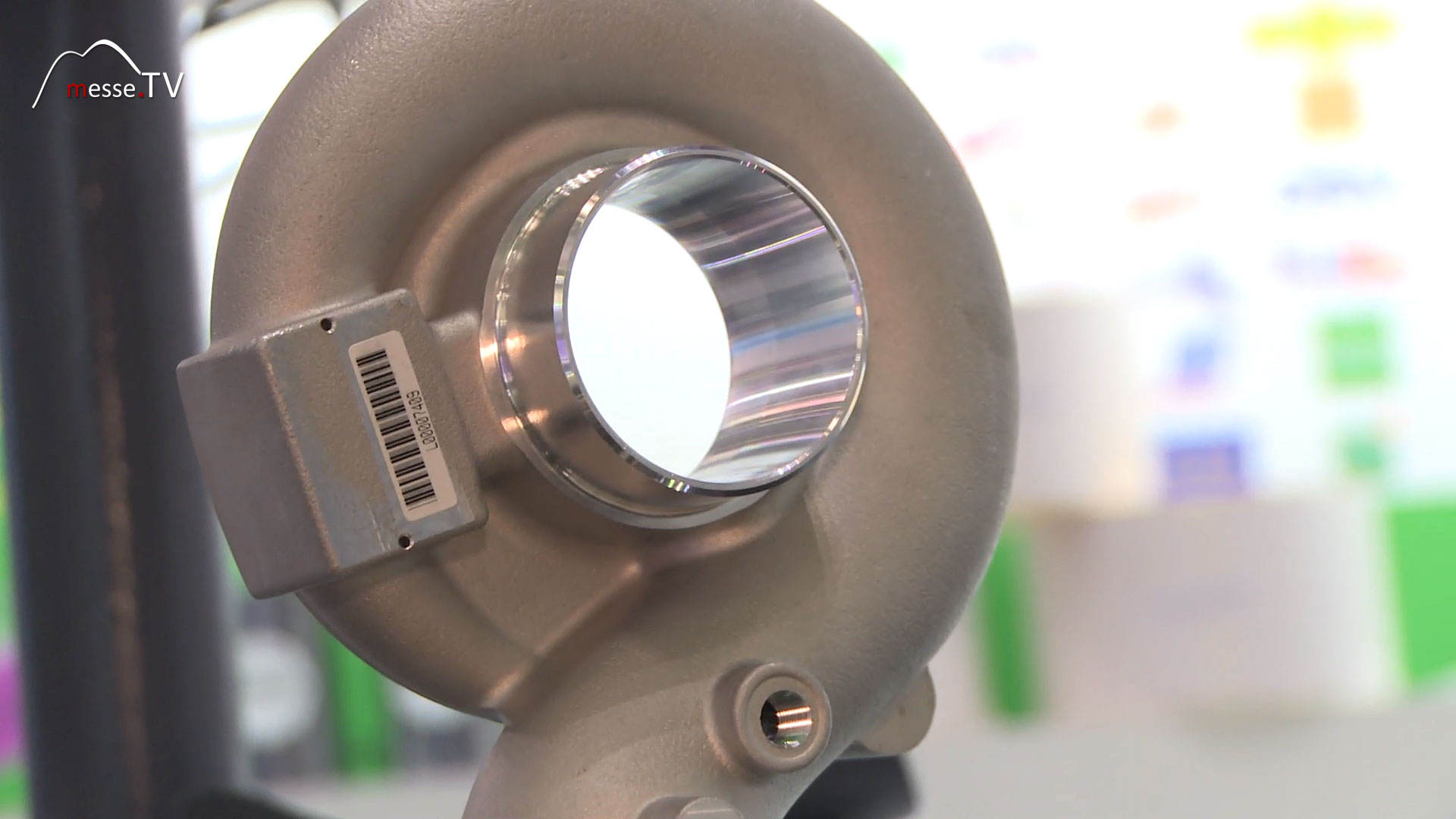

A key product is the Hvs32 multi-carrier shipping system. The software is designed to map a large number of different carriers within a single system. In practice, this means that shippers do not have to maintain separate processes for each service provider. Instead, requirements are managed centrally. Barcode support is particularly relevant here. Different carriers work with different specifications. Labels must comply exactly with the respective specifications to ensure smooth processes. The shipping system performs this task automatically. The barcodes are generated according to the specifications and printed directly onto the shipping labels. This reduces sources of error in the manual process. The large number of integrated carrier modules shows how fragmented the shipping market has become. National and international service providers, express delivery companies and specialised carriers must all be connected. The shipping software reflects this diversity and ensures uniform processes in the background.

In addition to the shipping software, volume recording plays a central role in the portfolio. It is relevant in both goods receipt and goods issue. In goods receipt, it is used to generate master data. Length, width, height and weight are recorded and stored as master data. This information is later crucial for storage, picking and shipping. Volume recording is used again in goods issue. Pallets and packages must be measured, especially in the air freight and express sectors. Discrepancies between actual and assumed dimensions quickly lead to recalculations. Such effects can be avoided through system-supported recording. Recording is not carried out as an isolated step, but is integrated into existing processes. The aim is to generate data where it is needed anyway, without additional manual effort.

A recurring theme in logistics is data quality. Inaccurate or missing information has an impact throughout the entire chain. Heidler addresses this problem by capturing data as close as possible to the physical object. Instead of estimates or subsequent corrections, reliable measurements are available. This data flows directly into the software processes. Shipping decisions are based not on assumptions, but on actual dimensions and weights. This increases planning reliability and reduces conflicts with carriers.

An important aspect is the integrability of the solutions. Logistics systems rarely stand alone. They must interact with merchandise management systems, warehouse management and higher-level IT structures. Heidler's solutions are designed to fit into existing system landscapes. This is not just a matter of technical interfaces, but also of process logic. The software is based on real processes in the warehouse and in shipping. The aim is to support employees, not to create additional complexity. Processes should become faster, more transparent and less prone to errors.

Many companies still view shipping as an operational cost factor. In fact, it is increasingly becoming a strategic lever. Delivery times, reliability and transparency have a direct impact on customer satisfaction and competitiveness. Shipping software plays a key role in this. In this context, Heidler positions itself not as a pure software provider, but as a partner for logistics processes. The combination of a multi-carrier shipping system and volume recording shows that efficiency is not achieved through individual tools, but through coordinated solutions.

Logistics continues to be under pressure to change. Rising volumes, increasing internationalisation and higher transparency requirements are shaping the market. At the same time, data is becoming increasingly important for controlling and optimising processes. Heidler is continuously developing its solutions against this backdrop. The focus on software, supplemented by data collection systems, demonstrates a clear strategic approach. Logistics is not viewed in isolation, but as an interplay of technology, data and operational reality. This is precisely where the strength of modern logistics software lies, thinking beyond pure shipping and supporting processes holistically.