Cleaning tanks, containers and silo vehicles is one of the most demanding tasks in industrial logistics. These containers are used to transport a wide variety of products – from food and chemicals to powders and liquids with special requirements.

The expectations in terms of hygiene, safety and process stability are correspondingly high. Cleaning systems must do more than just ensure cleanliness. They must deliver reproducible results, integrate into existing processes and, at the same time, be economical to operate. This is precisely where specialised system solutions come in, which do not view cleaning as an isolated process, but as a technically coordinated overall process. The combination of mechanics, control, energy generation and application determines whether a container is cleaned reliably or whether residues, downtime and high maintenance costs are the result.

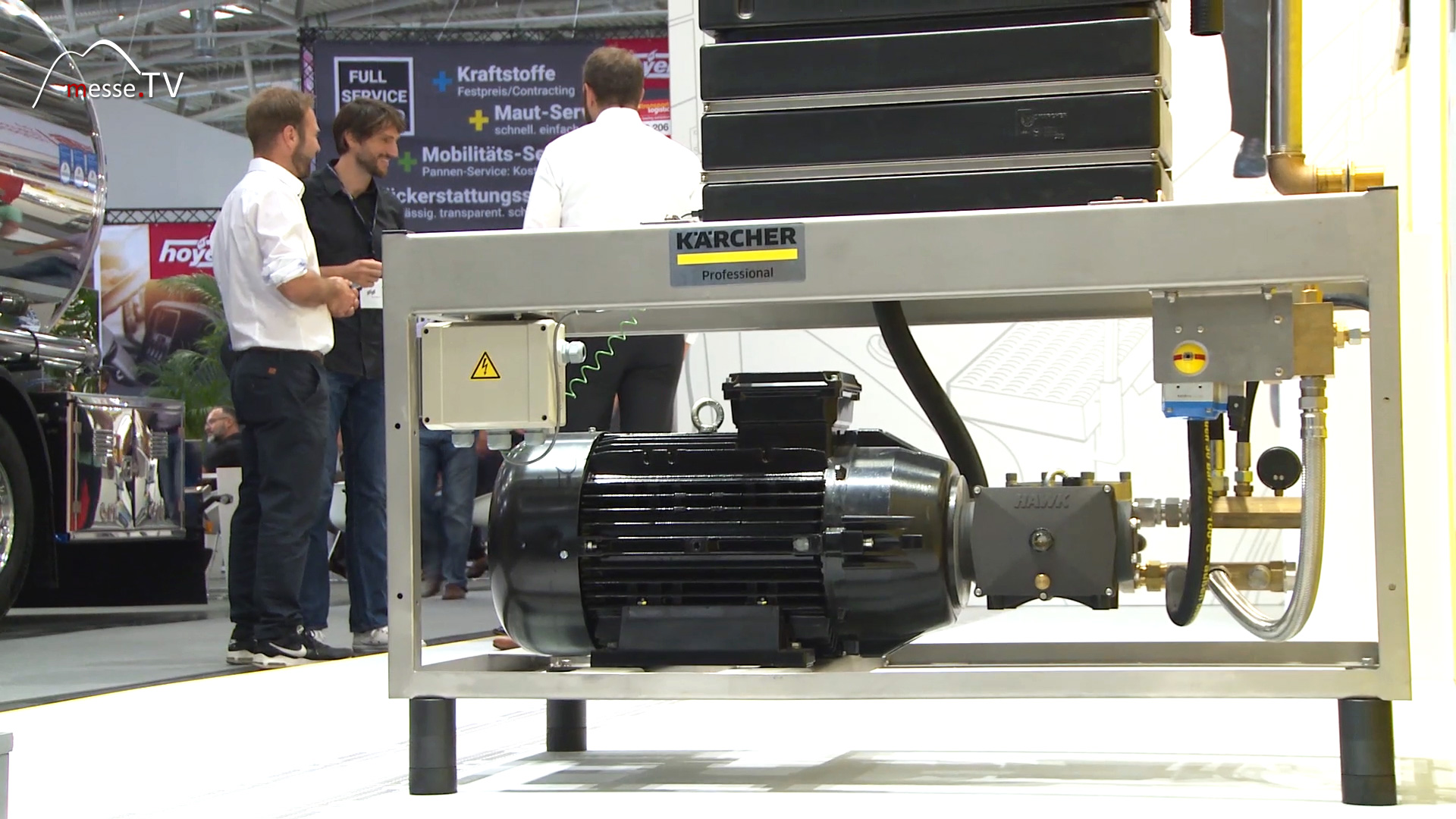

Kärcher develops solutions for the interior cleaning of tanks, containers and silo vehicles that are consistently tailored to the respective application. These are not standardised off-the-shelf products, but systems that are designed on a project-specific basis. Different transported media, changing temperatures and varying degrees of contamination require a precise analysis of the requirements. The cleaning systems consist of several functionally coordinated components. A central component is located in the technical room. Pumps and hot water generators are installed there, which provide the necessary energy for the cleaning process. These components form the backbone of the system, as they define the pressure, volume flow and temperature.

In addition to the mechanical design, the control system plays a decisive role. It ensures that all components work together functionally and that the cleaning process is reproducible. In practice, this means that pressure, temperature and movement sequences are precisely coordinated. The control system makes it possible to adapt cleaning programmes to different types of containers. Tanks differ not only in size, but also in geometry and surface properties. A flexible control system is therefore essential to achieve consistent cleaning results without unnecessarily prolonging the process or wasting energy.

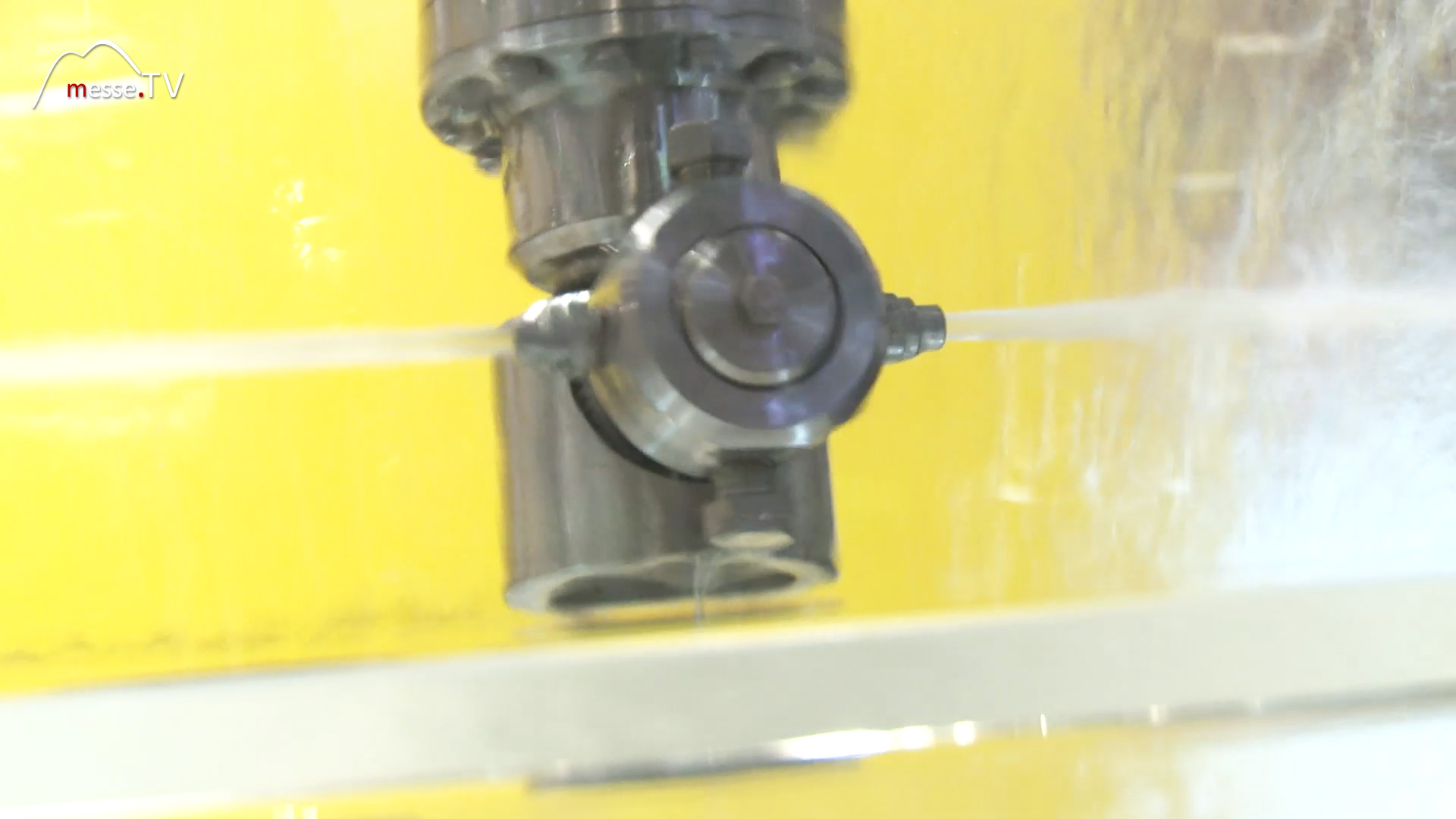

A key factor in the overall system from Kärcher is the tank interior cleaning head. This is the component that transfers the energy generated in the technical room directly to the container. Pressure and temperature are processed here in such a way that they take effect on the inner wall of the tank. The design of this cleaning head is a decisive factor in the efficiency of the system. It must be robust enough to cope with long operating hours, but at the same time work with precision. Uniform wetting of the inner surfaces is crucial for reliably removing residues and preventing cross-contamination.

An important innovation compared to previous solutions lies in the drive of the cleaning head. Instead of complex mechanical drives, a water turbine is used inside. This uses the existing energy of the water to generate the movements of the cleaning head. This approach significantly reduces the number of moving parts. Fewer components mean less wear and tear and thus greater operational reliability. At the same time, maintenance is simplified as fewer components need to be checked or replaced on a regular basis. The water turbine drive fits seamlessly into the existing cleaning process and makes efficient use of existing resources.

The cleaning systems are deliberately designed to be robust. In practice, this means that they can respond to different applications without the need for fundamental modifications. Tanks and silo vehicles are used in many industries, often under demanding conditions. Long operating times, changing media and tight time windows characterise everyday life. The design, which uses as few individual parts as possible, helps to make the systems durable. At the same time, maintenance is simplified for the operator. Minor interventions, such as replacing seals, can be carried out independently. This reduces downtime and lowers operating costs over the entire life cycle of the system.

In logistics and transport, time is a critical factor. Downtime has a direct impact on supply chains and cost structures. Cleaning systems must therefore not only work effectively, but above all reliably. A system that requires regular maintenance or causes unplanned downtime quickly becomes a bottleneck in operations. With their reduced complexity and robust design, the systems aim to minimise precisely these risks. Maintenance work can be planned, and minor repairs can be carried out on site. This increases the availability of the systems and ensures stable processes in day-to-day business.

The importance of cleaning the interior of tanks and silo vehicles is often underestimated. In fact, it is a central component of integrated logistics processes. Only when containers are reliably cleaned can they be used flexibly and quickly reloaded. Delays or quality problems have a direct impact on downstream processes. Kärcher therefore does not view cleaning in isolation, but as part of a larger system. The systems are designed to fit into existing infrastructures and support the logistics process rather than hinder it. Energy efficiency, ease of maintenance and process reliability are equally important.

The demands placed on cleaning systems will continue to increase. Stricter hygiene requirements, rising cost pressure and the desire for more sustainable processes are shaping developments. System solutions that are flexibly adaptable and operate stably over the long term are therefore becoming increasingly important. With its focus on individual project planning, robust technology and simplified maintenance, Kärcher addresses precisely these challenges. Cleaning thus becomes a predictable, reliable process – and a stable component of modern logistics and transport chains.