Everyday life at a transhipment terminal is characterised by repetition, time pressure and physical strain. Drivers move their vehicles every minute, get in and out, manoeuvre under swap bodies and have to work precisely at all times.

It is precisely these routines that determine productivity, safety and long-term health. In this environment, ergonomics is not a matter of comfort, but an operational factor. Relieving the driver's workload stabilises processes and reduces risks in daily operations. Modern handling vehicles therefore face a clear task: they must be functional, robust and, at the same time, designed with people in mind. Not through technical gimmicks, but through concrete improvements in areas where strain occurs. This is precisely where the further development of a well-known vehicle concept comes in, which was specifically designed from the driver's perspective.

Kamag has been established in the field of specialised transport vehicles for many years. The vehicles are used where standard solutions reach their limits, for example in swap body handling or in tightly scheduled logistics centres. In this environment, the Wiesel has been specifically redesigned, not with the aim of prioritising performance or speed, but to improve the driver's daily movements. The starting point was a simple observation: many drivers get out of their vehicles dozens of times during a working day. Depending on the application, this can be 80 or even 100 times. Every additional step, every awkward step and every restricted view adds up to a real burden over the course of the day. The redesign therefore addresses precisely these points.

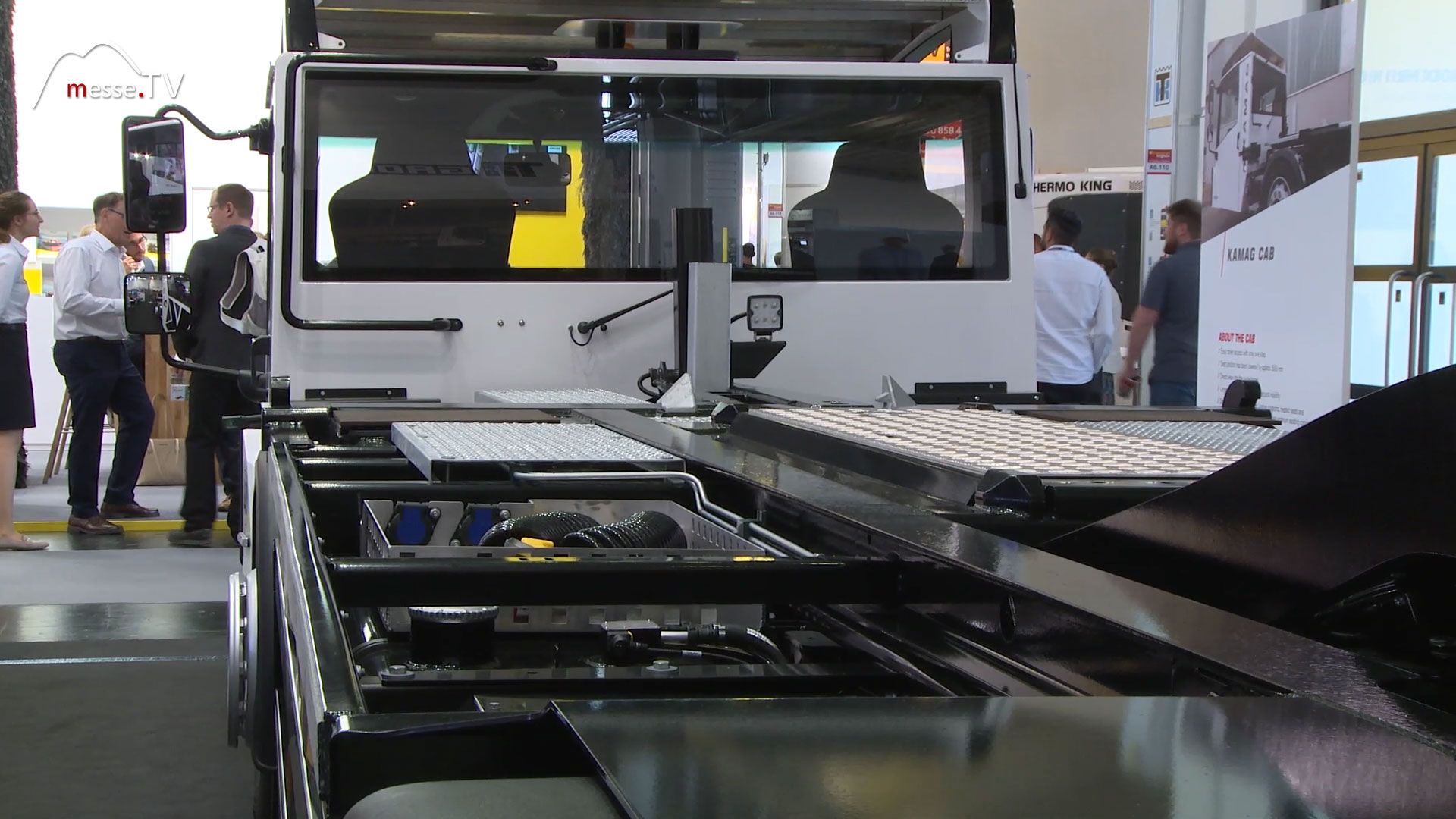

A central element of the further development is the low-mounted cab. It significantly shortens the distance when getting in and out. The driver can reach the ground more quickly and safely, especially when working directly on the swap body. Movement becomes smoother and requires less effort. This aspect should not be underestimated in daily operation. What at first glance appears to be a minor design change has a major impact on fatigue and movement patterns. Especially in shift operations or with high handling frequencies, a lower cab helps the driver to stay focused and reduces physical strain.

In addition to ergonomics when getting in and out, visibility plays a key role. Swap body handling requires precise manoeuvring, frequent reversing and exact positioning. Mistakes cost time and pose safety risks. The redesign of the vehicle therefore focuses heavily on improving visibility. A large windscreen significantly expands the field of vision to the front. At the same time, an equally large rear window ensures that the driver has a clear view of the relevant area when reversing. This direct visibility is a decisive advantage, especially when frequently driving under swap bodies. The driver has to rely less on mirrors or constantly adjust their posture and seating position. This reduces stress and increases safety, especially in confined terminal areas.

Reversing is part of everyday life in swap body operations. Drivers have to repeatedly position their vehicles precisely under the bridge. This happens not just once, but many times a day. Any improvement in visibility therefore has a direct impact on the workflow. The optimised glazing makes the relevant area easier to see. The driver can recognise distances, edges and positions more quickly. This reduces the need for corrective manoeuvres and speeds up the entire handling process. At the same time, it reduces the risk of collision or manoeuvring damage, which can be very costly in terminal operations.

The further development of the vehicle shows that ergonomics is not an end in itself. It has a direct impact on efficiency and safety. A driver who can move more easily, see better and is less physically strained works more consistently and with fewer errors. In an environment where time slots are tightly scheduled, this is a clear advantage.

In everyday logistics, many small factors determine whether operations run smoothly. Vehicles that are poorly designed ergonomically lead to breakdowns, errors and dissatisfaction in the long term. Improvements such as a lower cab or better visibility, on the other hand, have an impact over months and years. For operators, this means fewer downtimes, lower accident rates and more stable processes. For drivers, it means a workplace that supports their daily performance instead of making it unnecessarily difficult. This aspect is becoming increasingly important, especially against the backdrop of a growing shortage of skilled workers.

It is striking that the redesign deliberately focuses on practical improvements. It is not about additional displays or complex assistance systems, but about clear, comprehensible changes to the cab and fields of vision. This restraint is not a shortcoming, but an expression of a realistic understanding of everyday working life. The focus is on what drivers actually need: good visibility, simple movements and a vehicle that can be operated intuitively. Such characteristics are particularly important in terminal operations, where routine and repetition dominate.

Swap body logistics rarely takes place under ideal conditions. Cramped spaces, changing light conditions and high time pressure are part of everyday life. Vehicles must be designed to function reliably under these circumstances. The redesign of the Wiesel shows how technical adjustments can be directly tailored to these conditions. Improved visibility helps in poor lighting conditions, while a lower cab makes it easier to move quickly between the vehicle and the working environment. This makes the vehicle a tool that adapts to people, not the other way around.

The focus on the driver's workplace will continue to grow in importance in the future. Logistics companies are faced with the task of making workplaces more attractive and healthier. Vehicles play a central role in this, as they define the driver's workplace. With the redesign of the Wiesel, Kamag shows that this development does not have to remain abstract. Targeted, practical adjustments can measurably improve everyday working life. Ergonomics thus becomes an integral part of modern handling technology – not as an add-on, but as the basis for efficient logistics processes.