Beverage filling is one of the most sensitive stages of industrial production processes. Hardly any other area combines so many requirements at the same time: maximum hygiene, consistent product quality, minimal resource consumption and high ergonomic relief for operating personnel.

In breweries in particular, rising energy prices, stricter hygiene regulations and growing sustainability requirements are increasing the pressure on the technology used. Modern filling systems must therefore do much more than just fill containers. Current developments focus on a filling concept that does not view hygiene, efficiency and user-friendliness as contradictions, but systematically combines them. The focus is shifting from individual optimisations to holistic machine concepts that offer advantages in daily operation as well as in maintenance, cleaning and format changes.

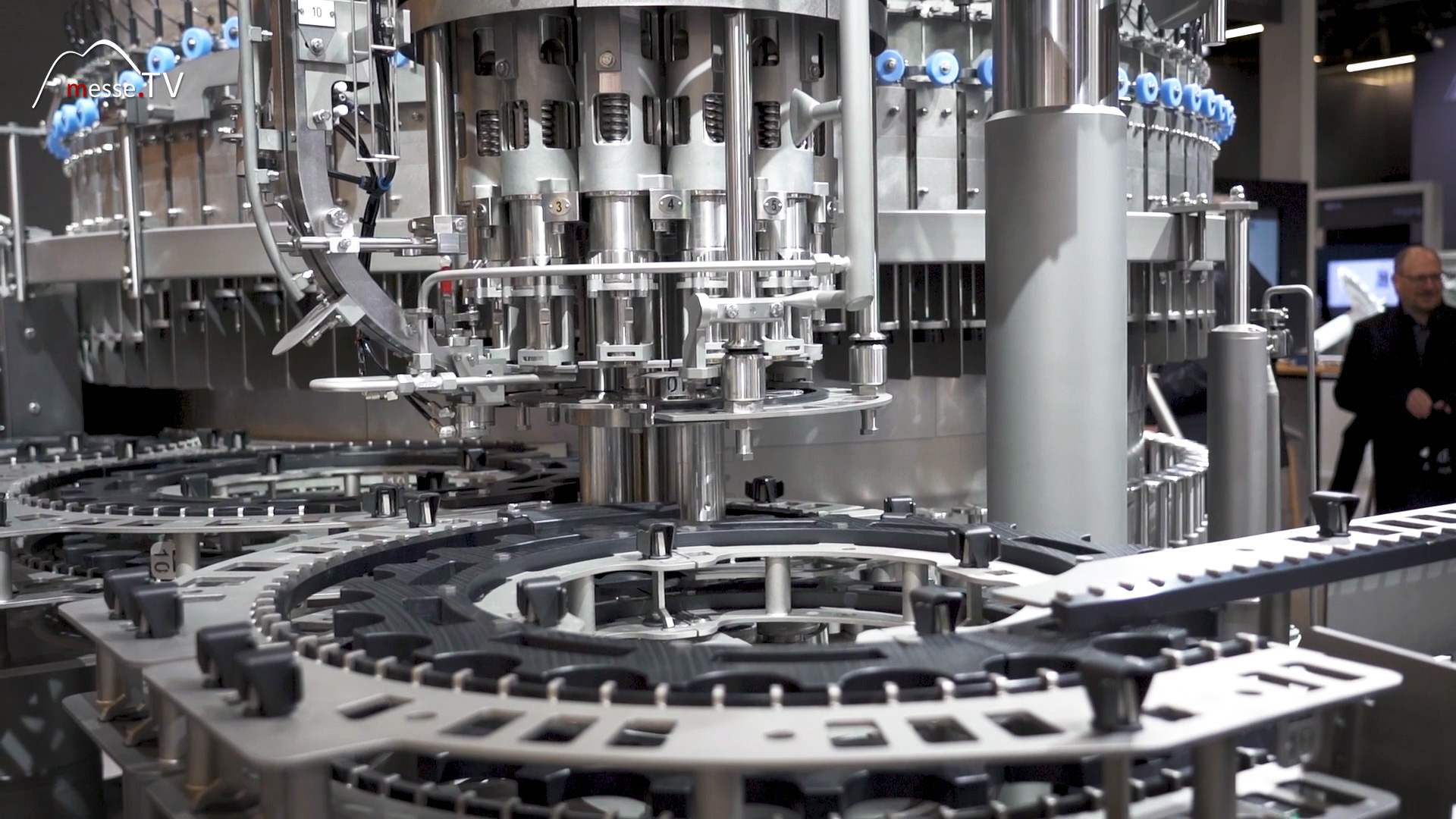

Beer fillers today are highly complex systems. They influence not only the output of a line, but also the shelf life of the product, the energy requirements of the brewery and the workload of the staff. Two aspects are particularly important here: the controlled handling of oxygen and the efficient use of CO₂. Excessive oxygen ingress during the filling process can significantly impair product quality. Oxidation has a negative effect on taste, stability and shelf life. At the same time, CO₂ is a cost-intensive operating resource, the consumption of which is increasingly viewed critically – both economically and ecologically. Modern filling systems therefore rely on design solutions that minimise oxygen ingress and significantly reduce CO₂ consumption.

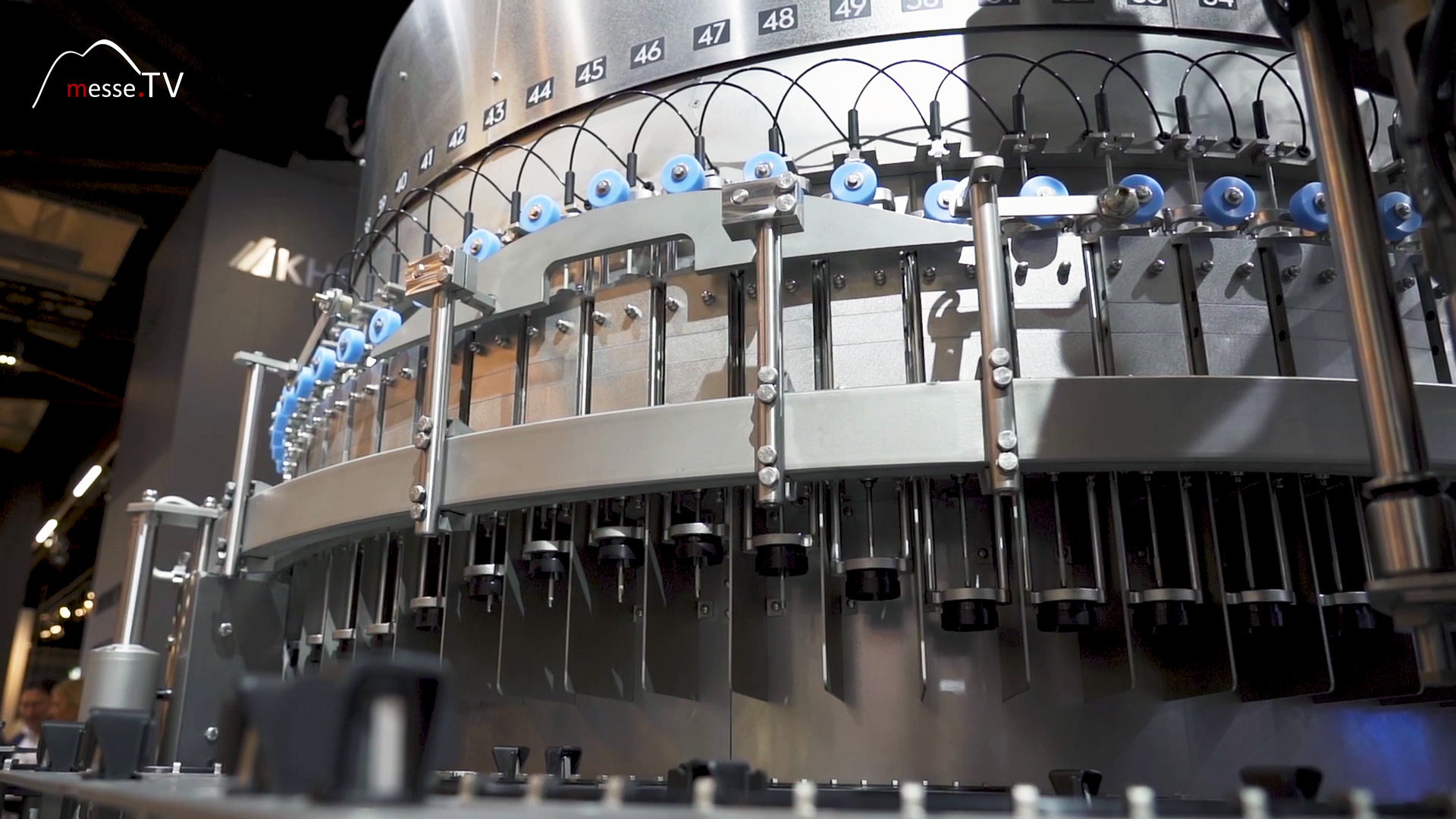

In addition to process reliability, hygienic design is becoming increasingly important. This is not just a matter of easy-to-clean surfaces, but of a well-thought-out overall concept. Open profiles, unnecessary horizontal surfaces or components that are difficult to access are now considered potential weak points. They can promote the accumulation of dirt, moisture or microbiological residues. A beer filler designed with consistent hygiene in mind takes these aspects into account right from the design stage. Smooth surfaces, clean lines and a reduced number of components make cleaning easier and shorten downtimes. This is particularly relevant in the event of malfunctions such as bottle breakages, where glass fragments and product can quickly spread throughout the machine room. This is where a design that allows for quick and thorough cleaning processes pays off.

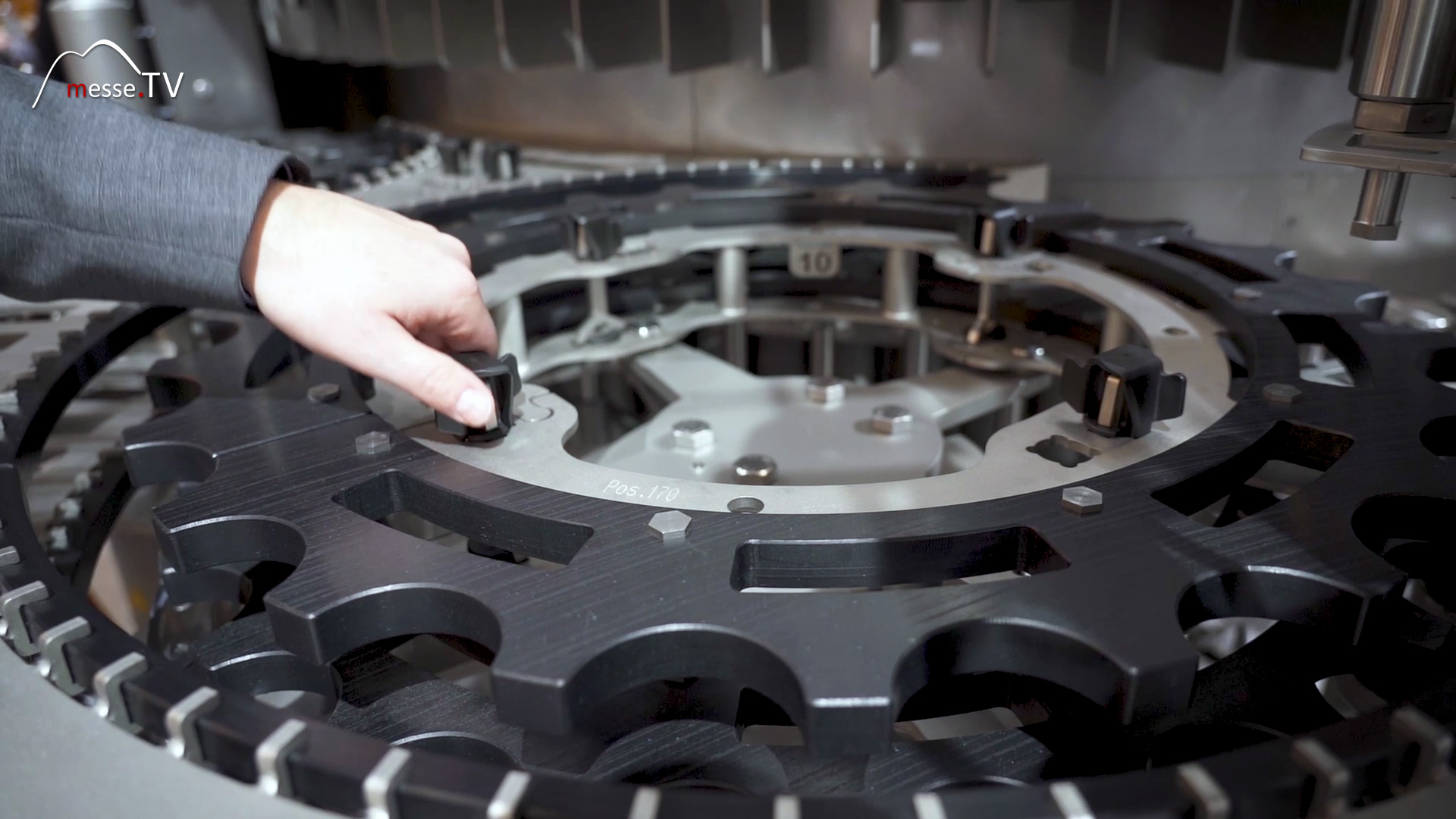

The human factor is also playing an increasingly important role. Operators face physically demanding tasks in their daily work, especially when changing format parts. Heavy components, awkward installation positions or complex changeover processes increase the risk of injury and prolong downtime. Modern fillers therefore rely on segmented format parts and intelligent quick-release fasteners. These make it possible to carry out changeovers without heavy lifting. The operator can change individual segments in a targeted manner, which not only has ergonomic advantages but also significantly reduces changeover times. At the same time, process reliability is increased, as clearly defined changeover points minimise the risk of errors.

A modern beer filler combines several technical approaches that respond to different challenges. These include, among others:

A concrete example of this approach is the DRS Eco filler, which was presented as the main exhibit at a recent industry trade fair. It is a classic beer filler whose mechanical basis follows proven design principles, but which has been further developed in key areas. The innovations lie less in the basic mechanics and more in the areas of hygiene, ergonomics and resource efficiency. A brewery's decision to opt for such a system is no coincidence. Rising energy and media costs are forcing operators to evaluate investments more closely from an economic perspective. At the same time, product quality remains non-negotiable. A filler that reduces both CO₂ consumption and oxygen ingress offers clear added value here.

Behind such systems are manufacturers with decades of experience in mechanical and plant engineering. KHS develops filling and packaging technology for the beverage and food industry and operates internationally. Its headquarters are in Dortmund, but it has production sites on several continents in order to be close to the respective sales markets. The development of the DRS Eco filler shows how much the focus in mechanical engineering has shifted. It is no longer just about performance data or output figures, but about holistic solutions that take ecological, economic and ergonomic requirements into account in equal measure. The manufacturer is thus positioning itself as a partner for breweries that want to secure their filling processes in the long term.

Bottling technology is a prime example of the changes taking place in the beverage industry. Investments in new machines are increasingly being viewed strategically. Aspects such as energy efficiency, CO₂ reduction and occupational safety are no longer just additional arguments, but key decision-making criteria. Beer fillers with consistent hygienic design, reduced media consumption and ergonomic conversion concepts show where development is heading. They enable breweries to respond flexibly to volatile markets, rising costs and stricter requirements – without compromising on quality and safety. In this area of tension, it becomes clear that modern filling systems are not just technical systems, but a decisive factor for the future viability of entire production sites.