The requirements for filling technology in breweries have changed significantly in recent years. Rising energy prices, growing cost pressure, higher hygiene standards and the desire for more flexible production lines are influencing the investment decisions of many companies.

Today, bottling plants must not only be reliable and efficient, but also simplify processes, save resources and reduce intervention by operating personnel. It is precisely at this interface between technology, economic efficiency and process reliability that the further development of modern beer fillers comes into play. The focus of current concepts is on the filling process itself. It determines product quality, shelf life and the efficiency of the entire line. Every unnecessary movement, every additional intervention and every consumption of media has a direct impact on costs and output. The demands on filling technology that combines these factors in an integrated system are correspondingly high.

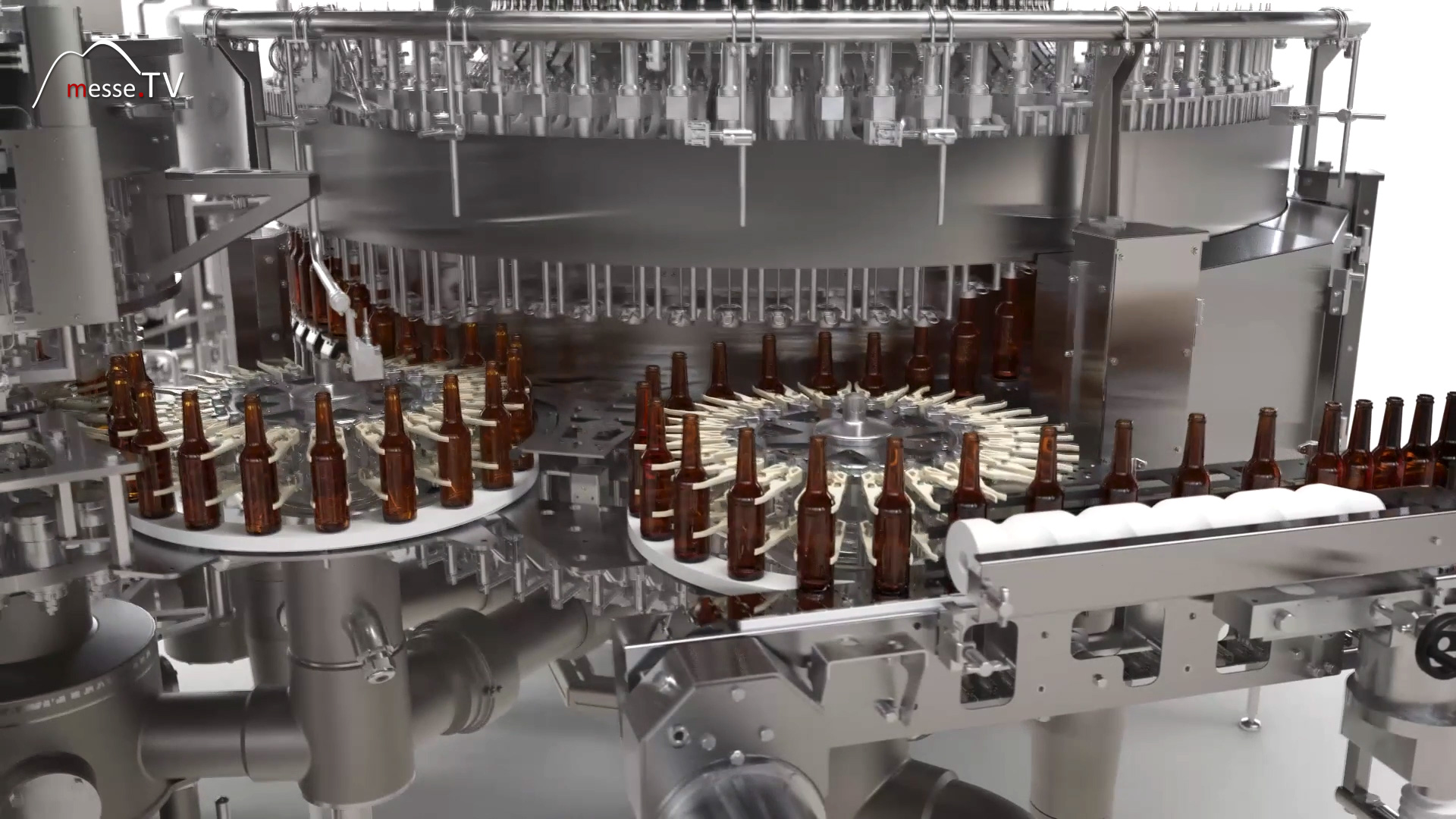

The beer filler is a central component of modern filling systems. It not only fills the bottles, but also controls the vacuum, rinsing and pre-stressing processes. The aim is to keep oxygen ingress to a minimum while ensuring a stable, reproducible filling process. This is particularly important for beer in terms of taste, shelf life and product safety. The advanced Modulfill HES is a prime example of this approach. Its design is based on a probe filling valve that is precisely tailored to the requirements of modern breweries. Vacuum and rinsing steps are firmly integrated into the process and ensure controlled conditions during filling. This reduces quality fluctuations and stabilises the process as a whole.

Another focus is on the flexibility of the system. Today's breweries need to switch between different bottle formats more frequently without incurring long downtimes. This is exactly where new solutions in bottle guidance come into play. The Multiguide star wheel enables format changes with virtually no changeover time. The bottle is guided stably, regardless of the format, which largely eliminates the need for mechanical adjustments. This form of format guidance not only reduces changeover times, but also lowers the risk of operating errors. At the same time, it reduces the workload on personnel, as heavy components no longer have to be changed manually. This increases the availability of the system, which has a direct impact on the economic efficiency of the line.

A key objective of modern filling technology is to reduce operator intervention. Every manual intervention potentially means an interruption to the process and an additional risk of error. Automated cleaning and maintenance functions help to reduce this dependency. One example of this is the automatic CIP cap, which is available for the first time for smaller filler divisions. It is integrated directly into the bottle plate and enables automated cleaning of the filling system. This standardises cleaning cycles, reduces operator intervention and increases process reliability. At the same time, it improves the predictability of cleaning, which has a positive effect on plant availability. Another technical step forward is the integration of a dry-running vacuum pump. It replaces classic, more maintenance-intensive solutions and reduces media consumption. Doing away with operating materials such as water or oil not only reduces costs but also simplifies system maintenance.

The filling process follows a clearly structured sequence designed for precision and repeatability. Starting with the single-section screw, the bottle is brought to the correct position and transferred to the filling carousel via the infeed star wheel. This is where the actual filling process takes place, comprising several precisely coordinated process steps.

The developments described are part of a more comprehensive approach to machine and plant engineering. Krones sees itself as a full-service provider for the beverage and food industry, with its systems covering the entire production process. From filling and packaging to higher-level line concepts, it offers technical solutions that are coordinated with one another. The focus is less on individual components and more on integration into existing lines. This holistic approach is becoming increasingly important, especially in international markets with different requirements in terms of formats, hygiene and automation. Krones is represented at numerous locations worldwide and incorporates this experience into the further development of its filling technology.

The further development of beer filling shows where the industry is heading. Efficiency, hygiene and automation are no longer isolated issues, but are intertwined. Systems such as the Modulfill HES illustrate that technical progress today is primarily achieved where processes are simplified, resources are conserved and operators are relieved of work. For breweries, this means greater flexibility, higher process reliability and a better starting point for economical operation under changing conditions.