Swing-top cap bottles pose special technical challenges for bottling plants. Unlike simple closures, several components must interact precisely to ensure hygiene, tightness, and brand image. The inspection of these components is therefore a central part of modern beverage filling—especially where high circulation figures and automated processes come together.

AMS Getränketechnik is based in southern Lower Austria and has been focusing on machines for swing-top closures since the mid-1990s. The focus is not on general filling solutions, but specifically on technology related to opening, closing, assembling, and testing swing-top bottles. This clear specialization shapes both the machine concepts and the inspection logic. Swing tops consist of several functional elements that are exposed to high mechanical and hygienic stresses in daily operation. Even small defects can cause bottles to close incorrectly or no longer meet the brewery's quality requirements. This is exactly where the inspection comes in.

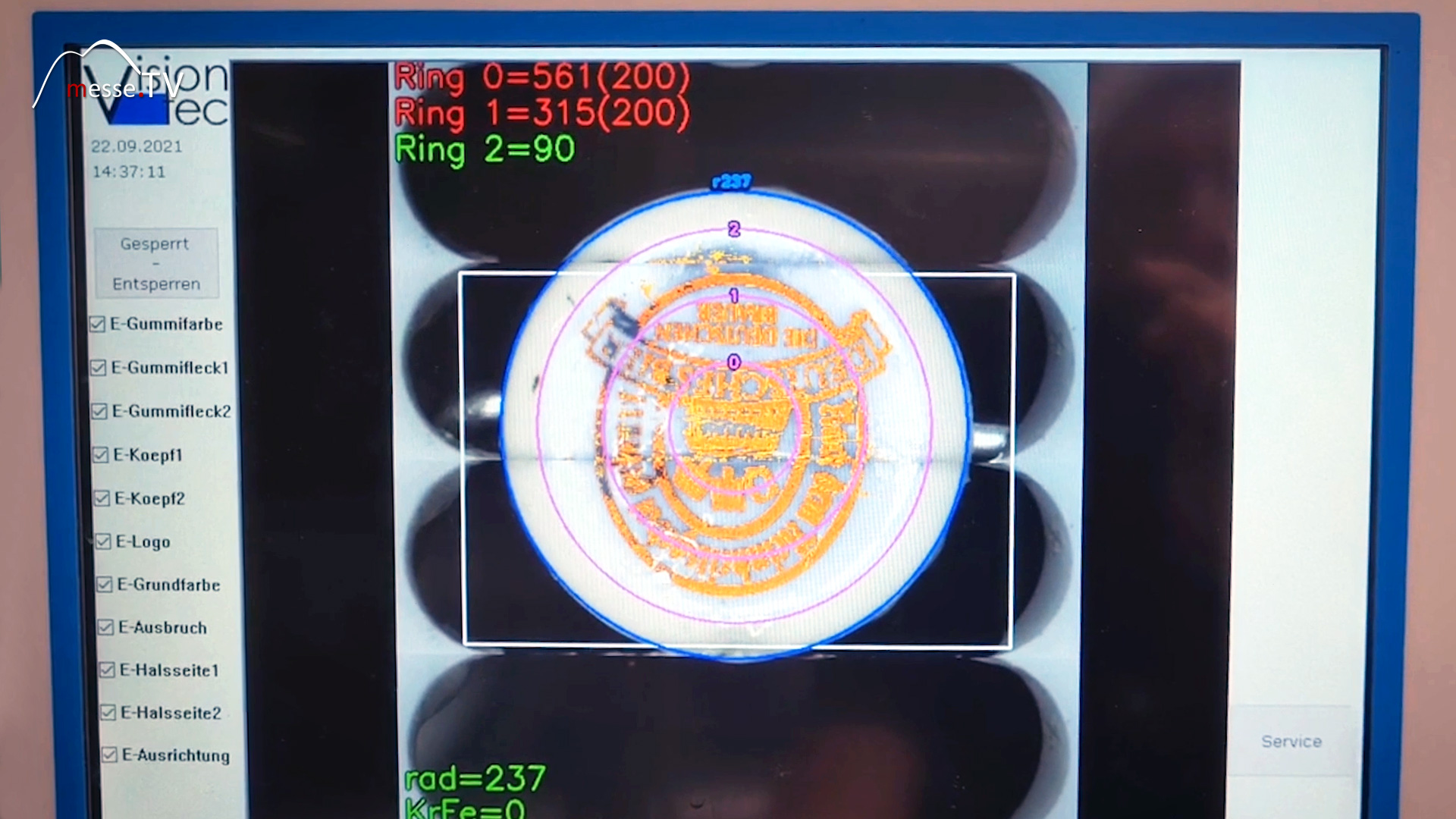

A central element of the inspection is the sealing rubber. It is checked for contamination, cracks, brittleness, or other damage. Mold or foreign matter can also be detected. In addition, the so-called clapper, which is made of porcelain or plastic depending on the design, is checked. Its condition is crucial for the function of the closure. In addition to the sealing rubber, the logo on the clip plays an important role. It is essential for breweries that the correct logo is present and correctly aligned. The inspection detects deviations as well as incorrect or missing logos. In addition, the bottle neck is checked to identify breakages or damage at an early stage.

The inspection machine has a modular design. The basic configuration focuses on checking the swing top and sealing rubber. Depending on requirements, the system can be expanded to perform a complete bottle inspection. This involves additionally checking the side wall, base, and mouth of the bottle. Other types of closures can also be integrated. Although the focus is clearly on swing-top bottles, crown caps, screw caps, and twist-off variants can also be inspected. This is particularly interesting for companies that process different types of containers on a single line.

Additional modules can be added to meet higher quality requirements. These include additional cameras that capture the bottle bottom or side wall, as well as systems for detecting label residues. It is also possible to check for residual liquid after the washing process. This allows you to determine whether there is still lye, water, or other residues in the bottle. The following inspection items, among others, are covered during the ongoing process

There are many inspection machines for bottles. The decisive difference here lies in the alignment of the swing top. The inspection uses the same alignment logic as a swing top sealing machine. The closure is positioned precisely and not detected randomly. This allows the clip and rubber seal to be detected and evaluated almost completely. This precise alignment ensures a very high detection rate. Instead of rough random samples, the result is a reproducible, documentable inspection that is specifically tailored to the geometry of swing-top closures. For bottling plants, this means significantly higher process reliability.

In practice, inspection contributes significantly to quality assurance. Leaky bottles, incorrectly mounted swing tops, or damaged rubber seals are rejected at an early stage. At the same time, the amount of manual inspection required is significantly reduced. The machine operates continuously, transparently, and is integrated into the existing line. This form of inspection is an important component, especially for reusable bottles that go through many cycles. It ensures that only flawless bottles are returned to the cycle. The technology thus makes a decisive contribution to hygiene, product safety, and brand quality in beverage technology.