We are at BrauBeviale for you. The first videos of the international trade fair for the production and marketing of beverages will be available this week on Messe.TV!

Wash-off labels for long-term use in reusable systems

Returnable bottles have been considered one of the most effective ways to reduce packaging waste for years. In practice, however, it is often not the bottle itself but the label that causes problems. Many self-adhesive labels adhere so firm... Wash-off labelsCollaborative palletising - Robotics in the palletising sector

In many production and logistics environments, palletising processes are among the areas in which automation is rapidly gaining relevance. Cartons weighing tens of kilograms, uniform movements and constantly repeated lifting operations repr... Palletising solution with robotsValve technology in beverage plants: reducing energy consumption

Compressed air is one of the largest, but often underestimated, energy consumers in beverage plants. New valve concepts show how demand can be significantly reduced without compromising process reliability or hygiene. One approach focuses d... Energy-efficient process valvesSelf-sufficient energy supply for breweries

The question of a stable and sustainable energy supply is becoming increasingly important in strategic decisions for breweries. Rising energy prices, regulatory requirements and pressure to reduce emissions are forcing operators to take a h... Sustainable brewing TechnologyWater treatment: Process water – reducing pollution

Clean water is no longer a matter of course in industry, but a critical production factor. In the brewing and beverage industry in particular, the question of how drinking and process water can be made permanently available, hygienically sa... Drinking water treatmentTransparent dispensing towers: Dispensing technology

The way beer is tapped and presented has long been more than just a technical issue. In bars, breweries and dining rooms, the dispensing system is part of the overall experience. It is visible in the room, shapes the first impression and co... Dispensing technologySpiral conveyors Vertical conveyor technology in logistics

Since the late 1990s, AmbaFlex has established itself as a provider of solutions for transporting products reliably and in a space-saving manner over differences in height. The focus is clearly on vertical conveyor technology with spiral sy... Vertical conveyor technology logisticsPreform production from recycled material for bottles

The manufacture of plastic packaging has been under particular scrutiny for years. Hardly any other industry is so directly confronted with issues of resource use, emissions, and sustainability. Doloop has been operating in this field for d... Sustainable packaging solutionsNano HCS can filler: Can filling for breweries

The Nano HCS can filler is aimed at companies that want to enter the can filling market for the first time and are looking for a compact, technically sophisticated solution. The focus is on small production volumes, flexible application opt... Can filling for breweriesDigital refrigerator as an autonomous vending machine

The sale of refrigerated products is facing a structural change. Where traditional sales areas, staff, and fixed opening hours were once necessary, automated solutions are increasingly emerging that function independently of time and place.... Refrigerator as an autonomous vending machineBeverage crates – individual designs and functionality

Beverage crates have long been more than just transport aids. In a market where brand image, ergonomics, and sustainability are increasingly influencing purchasing decisions, even seemingly simple packaging solutions are coming into focus. ... Beverage crates – individual designCan sealer with hygienic design and quick change

In industrial beverage filling, the final step determines the quality and stability of the product. The can closure is not only a mechanical seal, but also a safety-relevant process that must function reproducibly at high speeds. SmartCan can fillerCustomise lightweight borosilicate glass bottles

The market for drinking bottles has changed significantly in a short period of time. What used to be considered a purely functional object is now an expression of attitude, origin and material awareness. A young company that does not come f... Personalised glass bottlesPump technology and heat exchangers for the food industry

In the food industry, the demands on process technology are constantly increasing. Higher pressures, stricter hygiene requirements and, at the same time, the desire for more efficient, low-maintenance systems characterize the design of mode... Pumps & heat exchangers for the food industryInspection technology: Product safety in the beverage industry

Product safety requirements in the beverage industry have increased significantly in recent years. Increasing line speeds, new packaging formats and a growing degree of automation mean that errors must be detected earlier, more precisely an... Product safety in the beverage industrySustainable labeling of bottles in the recycling cycle

Current developments in the packaging market clearly focus on reusability, recyclability, and efficient material recovery. The focus is on technical label solutions that respond to new legal requirements while offering practical advantages ... Sustainable label solutionInspection of swing-top bottles - AMS

Swing-top cap bottles pose special technical challenges for bottling plants. Unlike simple closures, several components must interact precisely to ensure hygiene, tightness, and brand image. The inspection of these components is therefore a... Swing-top cap technologyTethered caps: Clip-Aside as a response to new requirements

On packaging, a closure often seems like a minor detail. In practice, however, it plays a decisive role in how well a product performs on the go, how clean the material cycle remains, and whether new requirements can be integrated into exis... Screw caps for the beverage industryBeverage Fittings, tap heads, and dispensing taps

Digital systems have been finding their way into areas where processes were long considered purely mechanical. The dispensing of beverages is one such area. In bars, restaurants, and at events, it is not only the product itself that determi... Dispensing technology with sensor technologyModern beer filling: Beer filler as a central component

The requirements for filling technology in breweries have changed significantly in recent years. Rising energy prices, growing cost pressure, higher hygiene standards and the desire for more flexible production lines are influencing the inv... Modern beer fillingDosing technology for water treatment in the beverage industry

In the food and beverage industry, it is not only the quality of the raw materials that determines the end product, but also the control of the accompanying processes. Water treatment and cleaning of the equipment are among the most sensiti... Dosing Technology BeverageModern beer fillers: hygienic design and energy efficiency

Beverage filling is one of the most sensitive stages of industrial production processes. Hardly any other area combines so many requirements at the same time: maximum hygiene, consistent product quality, minimal resource consumption and hig... Beverage fillingRotary decapper: high-performance operation in reusable systems

Reusable bottles place high demands on the technology that prepares them for the next cycle. Before cleaning, inspection and refilling can begin, closures must be reliably removed – quickly, gently and integrated into continuous lines. Removal of beverage closuresRecycled beverage crates for sustainable reusable logistics

Beverage crates are one of the inconspicuous but central components of reusable logistics. They are constantly in circulation, being stacked, transported, washed and refilled. This is precisely why the choice of materials, durability and re... Beverage crates made from recycled materialFilling systems: Filling machine for bottles and cans

Modern beverage production is currently under double pressure to adapt. On the one hand, the variety of containers is increasing, while on the other hand, the market and retailers are demanding short changeover times, manageable investments... Filling bottles and cansCompressed air: oil-free for sensitive production processes

Compressed air is one of the central production media in many branches of industry. Particularly in the manufacture of food, beverages, pharmaceuticals or electronic components, its quality has a direct impact on product safety and process ... Industrial compressed air for productionAutomation in filling plants with sensor technology

Modern automation is inconceivable without precise measurement data. In filling plants in the beverage, food and pharmaceutical industries, sensors determine whether processes run smoothly, whether quality remains reproducible and whether r... Level measurement with sensorsAutomated empties sorting with image processing and robotics

The return of reusable containers is one of the underestimated bottlenecks in the beverage and food industry. While filling and packaging lines have been consistently automated in recent years, handling unsorted empties has long remained a ... Empty container sorting in the reusable cycleAfter a four-year break due to the coronavirus, BrauBeviale was once again able to present the entire process chain of the beverage industry live and in person at the exhibition grounds in Nuremberg from November 28 - 30, 2023. BrauBeviale is regarded as one of the leading capital goods trade fairs for the beverage industry.

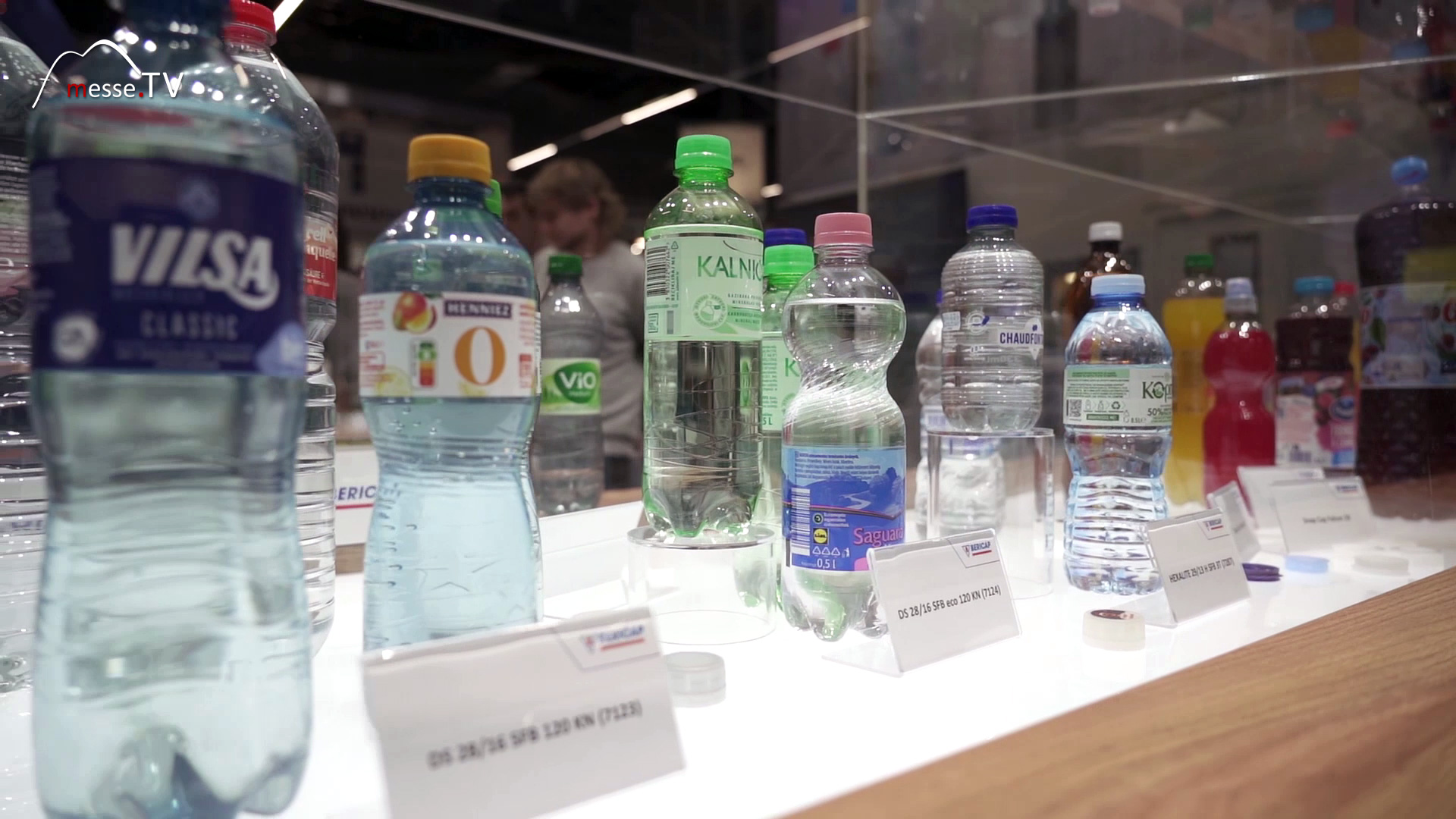

In addition to the changed trade fair date in November, there were other innovations to note in 2023. A new "Logistics Lounge" was set up in Hall 4. This focused on "Sustainable reusable logistics" and the European Packaging Ordinance (PPWR) and its impact on the industry. The new company YONTEX, a joint venture between drinktec from Munich and BrauBeviale from Nuremberg, also presented itself for the first time. The two trade fairs will remain independent brands, and the trade fair locations and dates will remain the same. The common goal is defined as bundling forces on the global market. BrauBeviale also broke new ground with a special "Grape processing and cellar management" area, where winegrowers could find out about solutions for their businesses and exchange ideas.

In summary, BrauBeviale 2023 was able to look back on three very successful trade fair days. Visitors from all beverage sectors from 120 countries took advantage of the wide range of exhibitors and the supporting program, in which current requirements and tasks were discussed. Energy saving, new filling systems, increased automation for greater efficiency and more sustainable production were the main focuses.

The event offers a wide range of products and services. It covers the entire beverage production process chain, from raw materials, technologies and components to packaging and marketing. In 2023, special attention was paid to the handling of raw materials with regard to climate change. International corporations and start-ups showcased every conceivable machine and system for producing beverages, from complete brewhouses to distillery accessories. Two exhibition halls were occupied by bottling plants for beverages of all kinds and packaging machines and packaging robotics, so that everyone could find the right solution for their product. The packaging itself was also presented in its entire range, from PET bottles to bag-in-boxes, as well as the corresponding closure systems and labels. The exhibition area with future technologies for energy supply, compressed air and gases as well as occupational safety and environmental technologies attracted a great deal of interest. The future viability of the beverage industry depends, among other things, on the sustainable use of resources. BrauBeviale has been attracting the European beverage industry since 1979. Its orientation is based on the 4-year cycle of drinktec, in these years BrauBeviale suspends its one-year rhythm. The next BrauBeviale is already on the horizon: it will take place from 26 - 28 November 2024 at the Exhibition Center Nuremberg.