Reusable bottles place high demands on the technology that prepares them for the next cycle. Before cleaning, inspection and refilling can begin, closures must be reliably removed – quickly, gently and integrated into continuous lines.

This is exactly where the rotary decapper comes into play, which is specially designed for high-performance operation in reusable systems and plays a key role there. The focus is not on the individual work step, but on the stable overall process. In systems where reusable bottles are processed at high cycle rates, decorking determines the throughput, availability and maintenance requirements of the entire line. The rotary decorker is designed to perform this function continuously and reproducibly – even under conditions where classic single stations reach their limits.

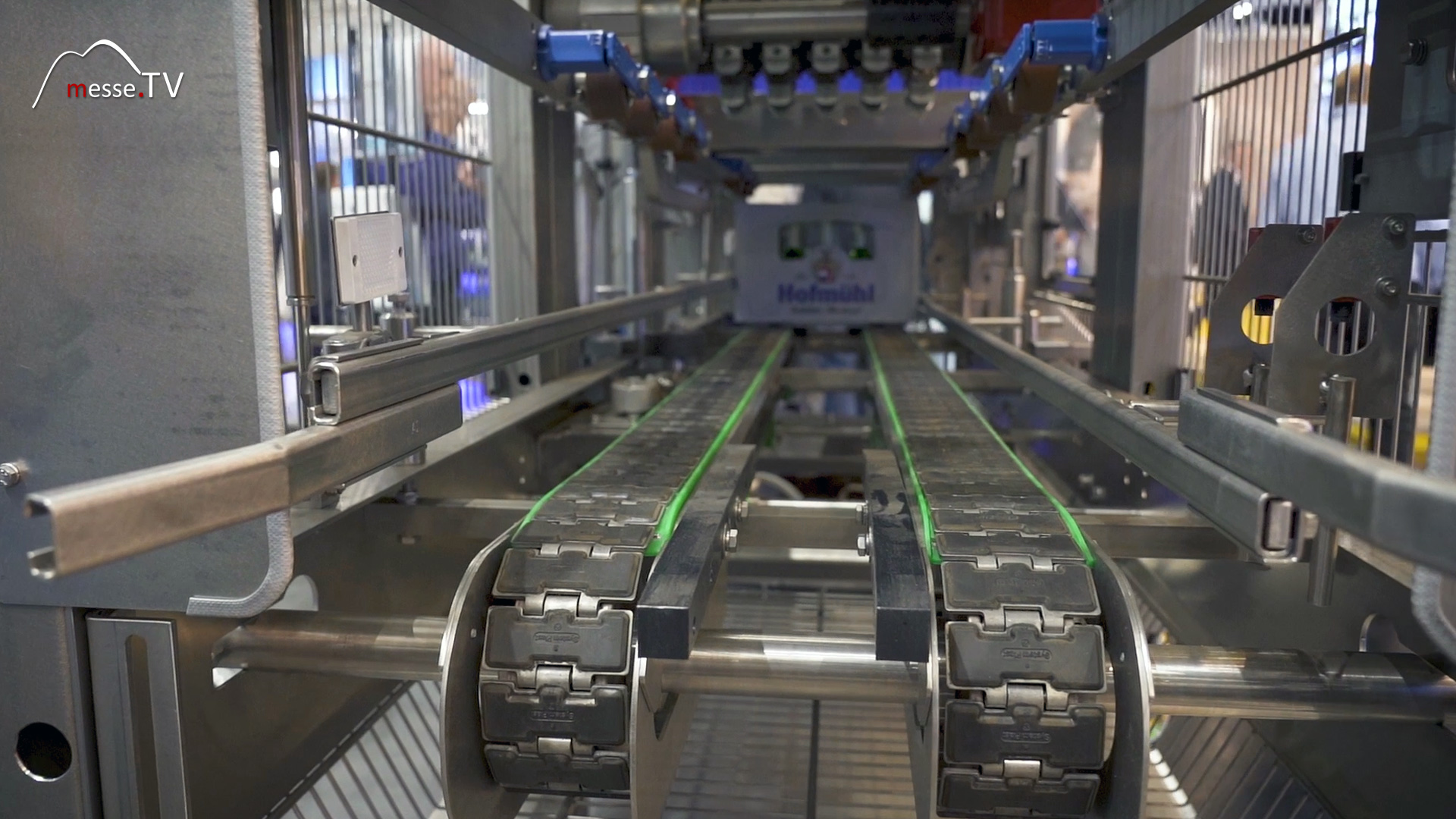

The technical approach is based on a rotating system that operates during running operation. Crates of returnable bottles are fed into the machine without interrupting the bottle flow. A rotating roller rolls over the bottle necks in a controlled manner, acting similarly to a manual opener, only automated and designed for industrial use. This movement cleanly separates the crown caps from the bottles. The removed caps are not collected in the work area, but are immediately removed from the process via a conveyor belt and collected in a separate container in front of the machine. This ensures tidiness, reduces downtime and facilitates the disposal or recycling of the crown caps. The decisive factor here is that the entire process takes place without individual manipulation of the bottles and can be seamlessly integrated into existing lines.

In returnable breweries with high throughput, consistent performance is crucial. The rotary decapper is therefore designed for high system performance and can deliver stable results even during continuous operation. The advantage of a mechanically clearly defined principle that does not require complex individual grippers or clocking movements is particularly evident in high-performance operation. Typical conditions of use are lines in which large numbers of returnable bottles are processed, for example in national or international bottling plants. Here, it is not only maximum performance that counts, but also operational reliability over long periods of time. The machine is designed to work reliably under these conditions and to reduce downtime to a minimum.

Returnable bottles differ significantly from disposable containers in terms of material, closure type and condition. Wear, contamination and varying cork qualities must be taken into account in the process. The rotary decorker has been specially developed for this area and addresses precisely these challenges. Typical features of such applications are:

In addition to direct business with breweries, the technology is also used in cooperation with large plant manufacturers. In such cases, it is crucial that the rotary decapper fits seamlessly into higher-level line concepts and that the interfaces are clearly defined. The machine is not viewed as an isolated unit, but as part of an overall process that ranges from empty container acceptance to refilling. This type of integration requires a deep understanding of line layouts, cycle times and maintenance concepts. This is precisely where the strength of specialised suppliers such as Rink lies, as they have been focusing on this type of machine for decades and have the relevant experience in a wide variety of plant configurations.

The rotary decapper occupies a special position in the market for decapping machines. The system is considered a unique selling point, as no other supplier produces it in this form. This clear focus allows the machine to be consistently further developed and tailored to the real requirements of the reusable markets. Rink does not act as a generalist, but as a specialist for precisely this process step. This is evident both in the design and in the fact that the machine is used worldwide wherever high-performance returnable beer is produced. In such applications, it is not so much the variety of machine types that counts, but rather the reliability of a clearly defined solution.

In high-performance operation, the rotary decapper is more than just an upstream function. It stabilises the entire line process by preparing bottles evenly and without interruption for the subsequent steps. Especially in large plants, this stability determines whether a line can consistently achieve its planned performance level. The combination of continuous bottle flow, robust mechanics and clear process control makes the rotary decapper a central component of modern reusable bottle filling. Suppliers such as Rink have specialised in precisely this area, serving a sector that is often less visible to the public but remains crucial to the operation of a brewery.