In many production and logistics environments, palletising processes are among the areas in which automation is rapidly gaining relevance. Cartons weighing tens of kilograms, uniform movements and constantly repeated lifting operations represent a considerable ergonomic strain.

At the same time, these activities add little value, tie up personnel and offer limited flexibility. Against this backdrop, collaborative robot systems are increasingly coming into focus because they address precisely this interface between efficiency, ergonomics and easy integration. Unlike traditional industrial robots, which operate in isolated safety cells, collaborative robots are designed to work directly with humans. Integrated safety technologies enable operation without massive protective enclosures, which reduces space requirements and facilitates integration into existing production lines. This opens up new possibilities, especially for palletising tasks, because processes can be adapted more quickly and automated economically even for smaller quantities.

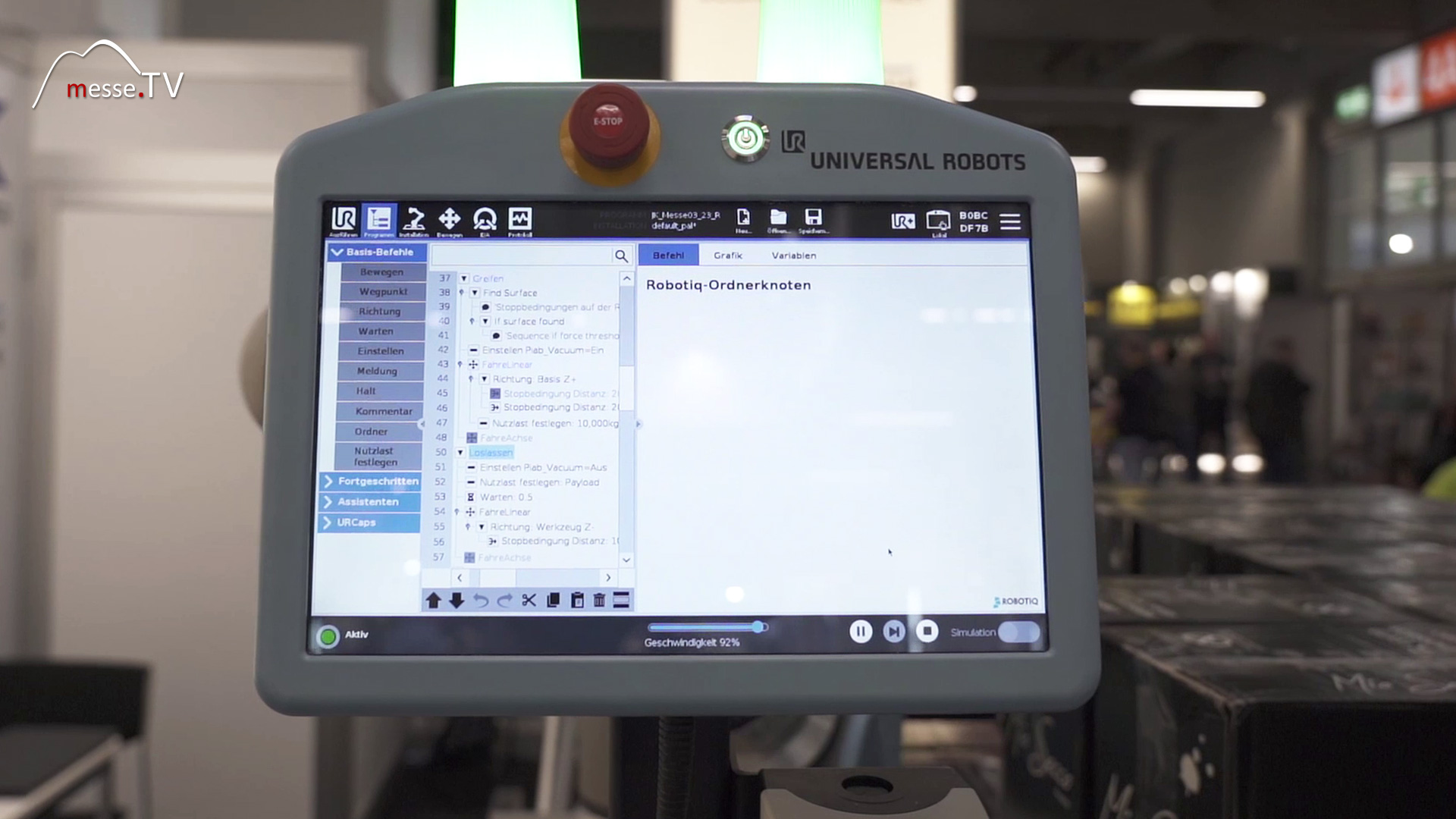

A key driver for the spread of collaborative palletising solutions is the increasing standardisation of components. Modern systems rely on preconfigured plug-and-play modules that can be put into operation without in-depth programming knowledge. The robot arm, gripper, software and palletising logic are coordinated in such a way that users can implement the solution largely independently. Vacuum grippers that pick up cartons using negative pressure are typical for such applications. These grippers are capable of safely handling different carton sizes and moving loads in the range of ten to fifteen kilograms. This means they cover the majority of palletising tasks that arise in practice. At the same time, they allow packaging to be handled gently, which is particularly important for sensitive products.

The use of collaborative robotics in palletising is not primarily aimed at replacing jobs, but at reducing physically demanding tasks. Monotonous lifting and stacking work is considered ergonomically unfavourable and is often the cause of absences due to illness. By automating these processes, employees can be relieved of heavy routine tasks and instead be assigned to supervisory, coordinating or skilled tasks. In addition, collaborative systems can react flexibly. They can be rearranged, reconfigured or integrated into other process steps as required. This is particularly relevant for companies that work with changing products, different packaging formats or varying batch sizes. Robotics thus becomes not a rigid element, but an adaptable tool within production.

At their core, collaborative palletising systems are based on robots with integrated sensor technology and safety functions. These detect resistance, stop on contact and adapt their movements to the environment. This technology is complemented by gripper systems specially designed for carton handling and software solutions that allow easy parameterisation. Typical features of such systems are:

Specialised sales partners play an important role in the practical implementation of such concepts. Jugard & Künstner is a medium-sized distribution company that has been active in the industrial sector for many decades and acts as a regional partner for collaborative robotics. The focus is on providing complete, coordinated palletising solutions that can be implemented without high integration costs. An application is shown in which a collaborative robot arm is used in combination with standardised palletising modules. The aim is to provide users with a solution that they can implement and operate independently. The approach is particularly aimed at companies that want to take their first steps towards automation without having to accept extensive conversions or long project durations.

Collaborative palletising is an example of a change in industrial automation. Instead of isolated high-performance systems, flexible, people-oriented solutions are coming to the fore. They combine technical efficiency with ergonomic improvements and open up new possibilities for workplace design. This approach is becoming increasingly important, especially in times of skilled labour shortages and rising occupational safety requirements. Automation is thus not an end in itself, but rather a tool for improving working conditions and making processes fit for the future. Collaborative robotics in the palletising sector shows how these goals can be achieved in practice.