Modern beverage production is currently under double pressure to adapt. On the one hand, the variety of containers is increasing, while on the other hand, the market and retailers are demanding short changeover times, manageable investments and stable processes.

Filling systems must therefore be flexible without compromising process reliability. This is precisely where a system concept that processes bottles and cans in a single line and enables quick changes between the systems comes into play. The focus is on modular machines that are not designed as rigid production lines, but as a continuous process from loading, cleaning, filling and sealing to inspection and transfer to packaging. The requirement is clear: to bundle as many production steps as possible in one system while handling different container shapes.

The process begins with the handling of empty containers. Bottles are not fed in individually, but are picked up by the pallet. Several bottles can be removed from the pallet at the same time and placed on the transport system. This approach reduces manual intervention and ensures a consistent flow of material. Cans follow a different principle. They are placed on a feed table and automatically forwarded from there. Both types of containers are then fed to the labelling station. The labelling machine is designed to guide both bottles and cans safely and label them precisely. The decisive factor is not so much the absolute speed as the process stability, as labelling errors would result in subsequent ejections.

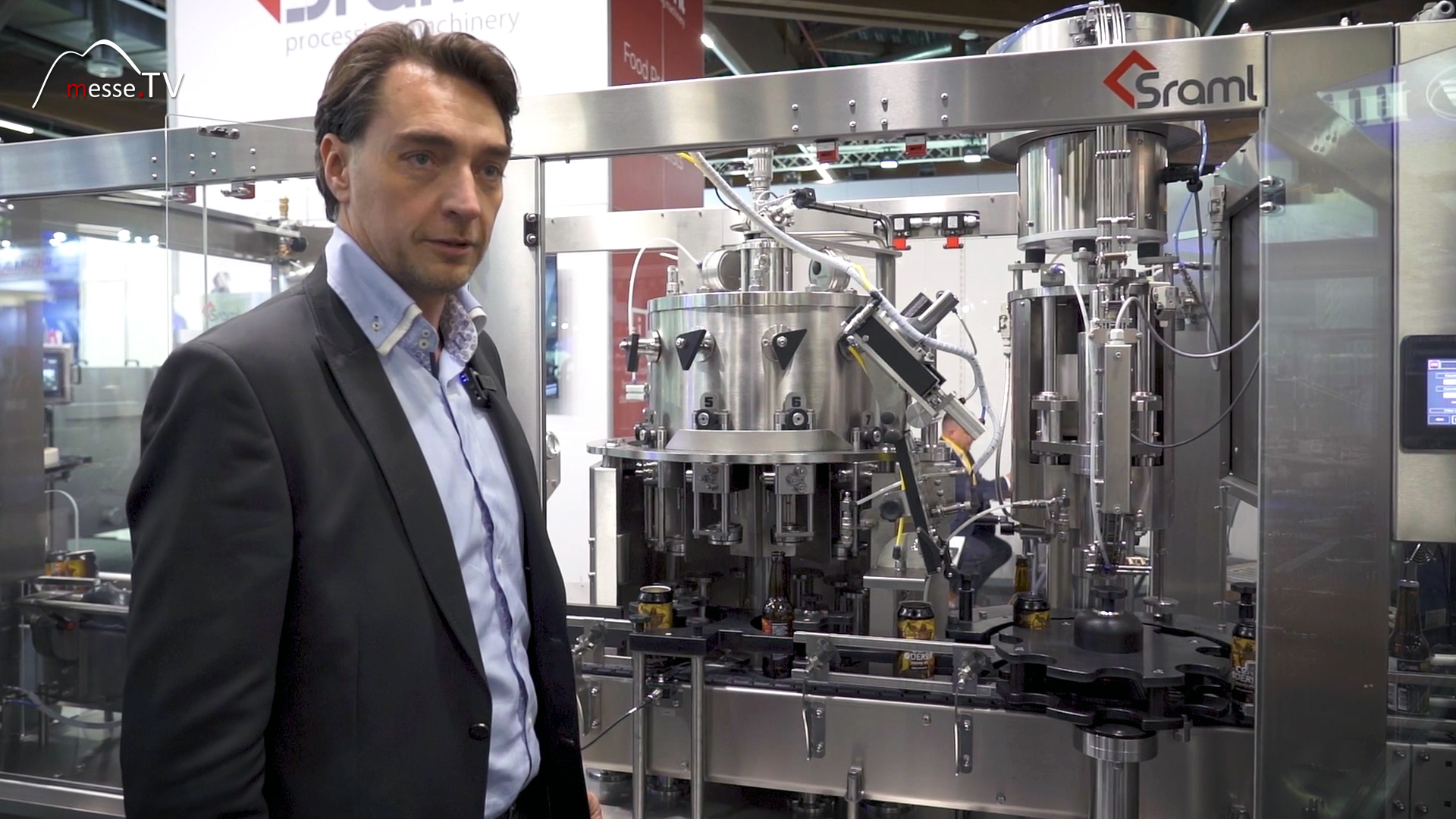

The heart of the system is the filling machine. This is where it is decided whether flexibility is actually implemented in a production-ready manner. Bottles and cans are first turned, rinsed and prepared for filling. Only then do they enter the actual filling process. A counterpressure filler designed for carbonated beverages is used. This technology is well established and ensures gentle filling with consistent quality. The containers rotate through the filler, are filled and then sealed immediately afterwards. The precise coordination between the filling valves and the sealing unit is crucial here.

A key feature of the system is its short changeover time. The changeover from cans to bottles – and back again – is designed to be routine rather than an exception. Calculations show that the changeover can be completed in a matter of minutes. This makes the system particularly suitable for small and medium-sized batches or for producers who regularly fill different products. This is achieved technically by means of rotatable and interchangeable modules. The capper plays a key role in this. It can be rotated 180 degrees and, depending on its position, works with either cork closures or can closures. There is no need for time-consuming dismantling or long downtimes.

The process does not end after capping. The containers are weighed to ensure that the fill quantity is within the defined tolerances. If a container falls below the target weight, it is automatically ejected. This step is essential to avoid complaints and quality losses. This is followed by further cleaning and drying of the containers. Only then are the bottles or cans transferred to the packaging. The system thus forms a self-contained line that integrates all essential process steps. Typical features of this system concept are:

This plant concept is developed and manufactured by Sraml. The company originates from the Slovenian coastal region and has a broad machine portfolio. In addition to filling systems, the range also includes solutions for wine and juice production. The machines are used worldwide by both small businesses and professional beverage manufacturers. Sraml pursues a clear approach: instead of highly specialised individual machines, it offers flexible systems that can be adapted to changing production requirements. This versatility is a decisive factor, especially in the international market, where batch sizes, packaging types and products vary greatly.

For many beverage producers today, the question is no longer one of maximum output, but of economic adaptability. Systems that are optimised exclusively for one type of container quickly reach their limits. Flexible filling systems, on the other hand, open up the possibility of testing new products, covering seasonal peaks or serving different markets without having to invest in new technology every time. In this context, modular concepts are gaining in importance. They combine proven processes such as counter-pressure filling with design flexibility. For suppliers such as Sraml, this is less a short-term trend than a long-term response to a changing beverage market.