Automated empty container sorting with vision systems in the reusable cycle

The return of reusable containers is one of the underestimated bottlenecks in the beverage and food industry. While filling and packaging lines have been consistently automated in recent years, handling unsorted empties has long remained a manual labour-intensive task.

Pallets with randomly stacked beverage crates, as they return from food retailers, must be unloaded, sorted and returned to an industrially usable condition. This is precisely where automated empties sorting comes in, which is increasingly establishing itself as a key technology for efficient reusable logistics.

Manual bottlenecks in a growing reusable system

Reusable packaging is regaining importance throughout Europe. However, increasing return volumes, heterogeneous crate formats and limited space in shops mean that empties rarely come back on clean pallets. Instead of neatly stacked units, there are unstable stacks that have previously been dismantled mainly by hand. At large locations, several thousand crates have to be moved per hour – a monotonous, physically demanding task that requires a lot of personnel and has a corresponding potential for errors. Automation at this point is technically challenging because there is no defined state. Each stack differs in terms of the position, height and orientation of the crates. Classic conveyor technology reaches its limits here because it relies on reproducible geometries.

Vision-based sorting as a technological approach

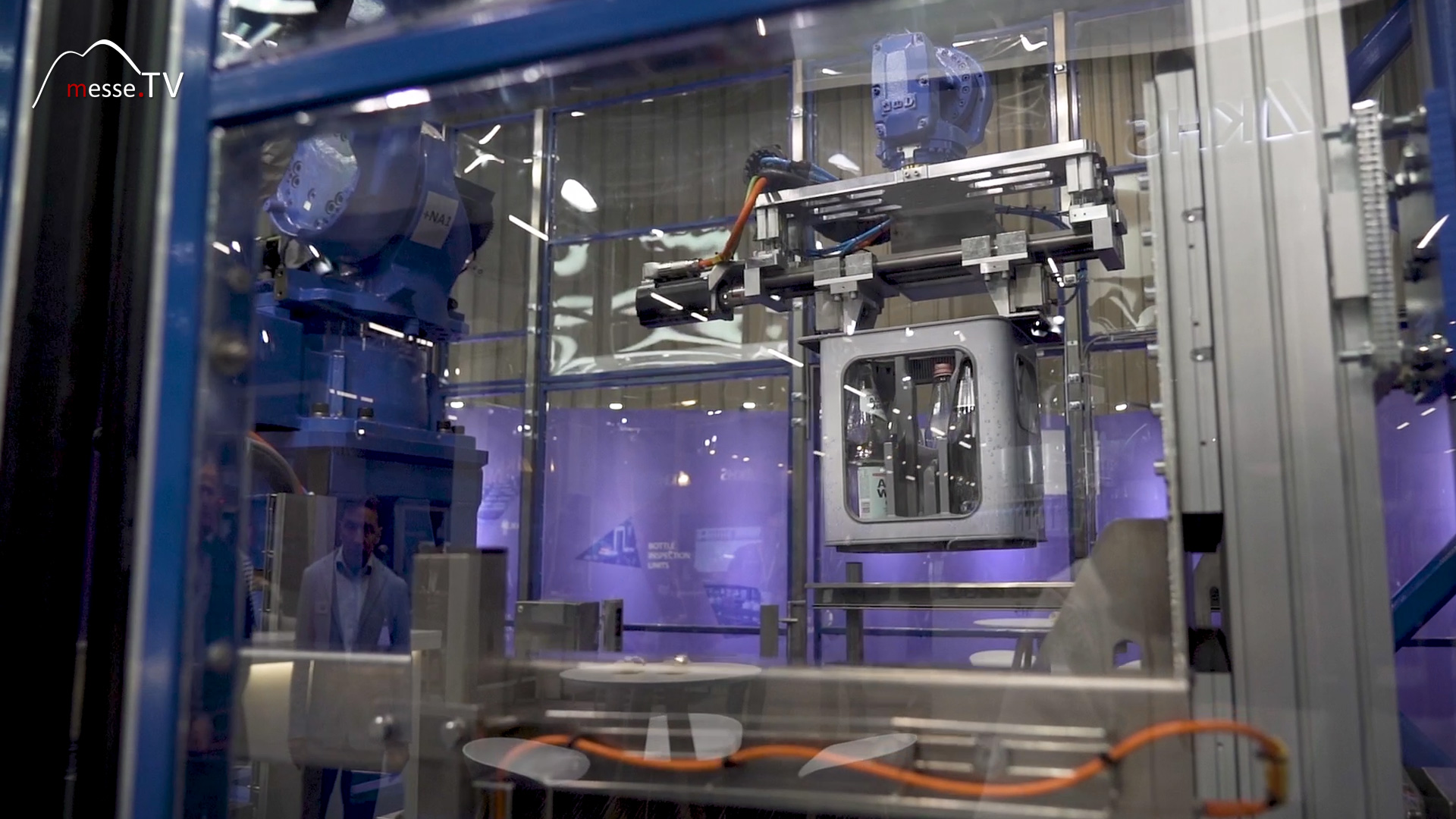

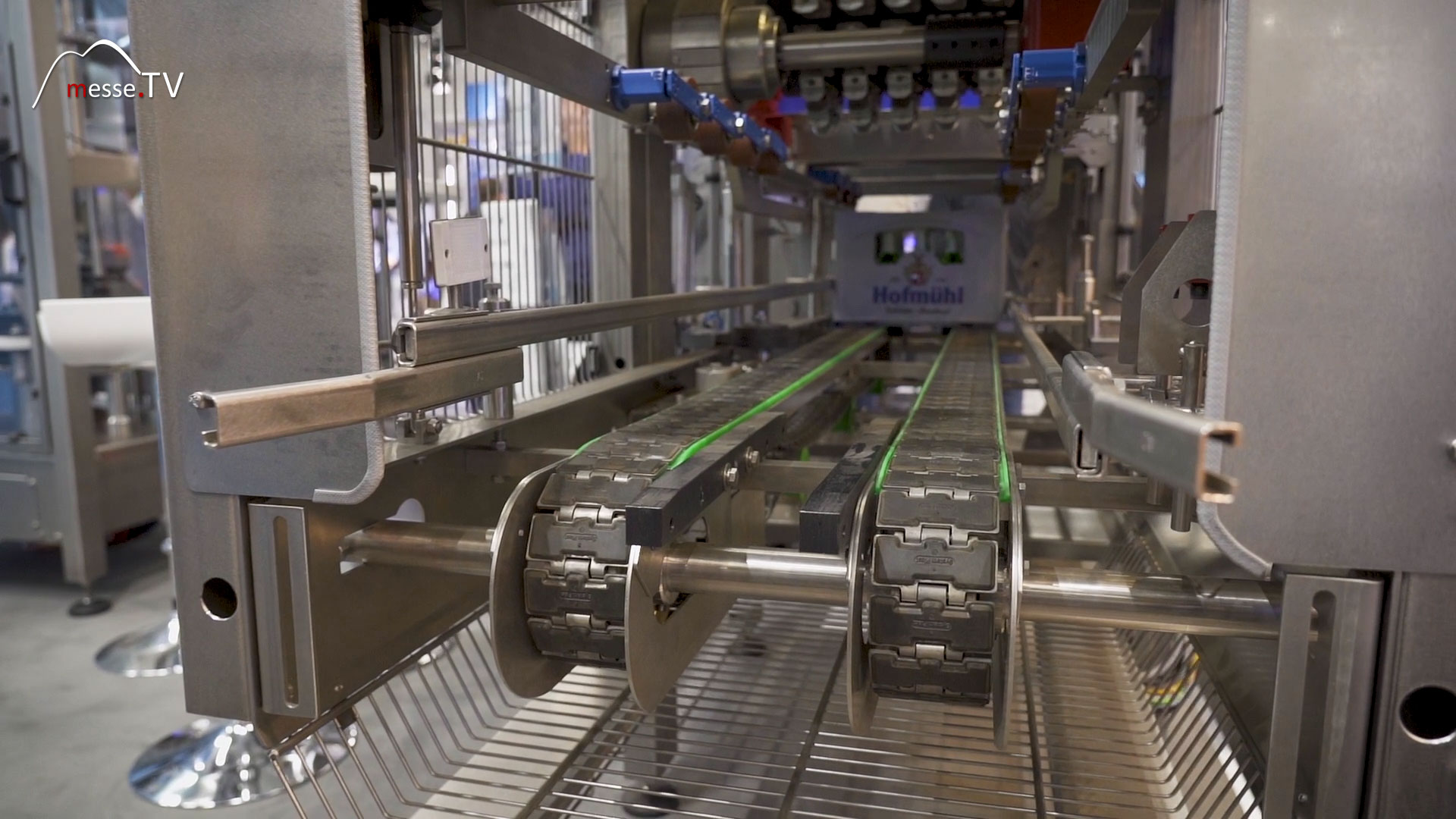

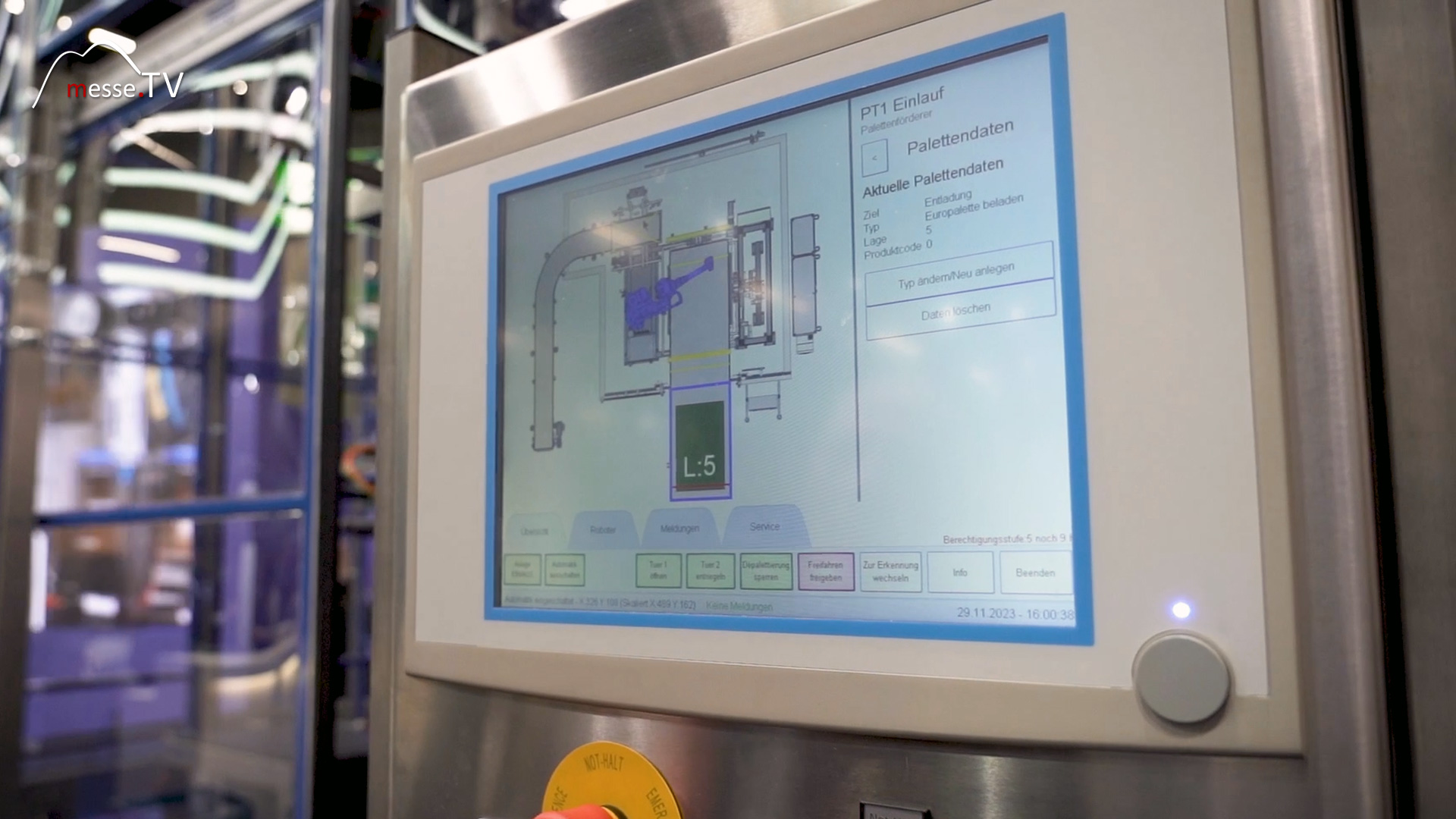

The core of modern empties sorting lies in the combination of image processing and robotics. Instead of relying on rigid mechanics, a 3D camera system continuously analyses the current situation on the pallet. It records not only the position of the crates, but also their relative height and accessibility. On this basis, the crate that is easiest to remove is identified – often the one that is highest or most accessible. After each gripping process, a new image is taken. The system thus reacts dynamically to every change in the stack. This continuous re-evaluation fundamentally distinguishes vision-based empties sorting from classic automation solutions that work with fixed sequences.

The magic cube as the answer to chaotic returns

The system developed by Vision-Tec, called the magic cube, is designed precisely for this task. It automatically unloads unsorted pallets and directs the crates into an orderly material flow. A specially developed gripper head allows it to securely grasp different types of crates, regardless of manufacturer or geometry. This means that the system is not limited to a single reusable system, but is designed for real mixed operation. The system works according to a clear sequence:

- Fixing the load to stabilise the stack

- 3D detection of the current box position

- Algorithmic selection of the optimally graspable box

- Removal by the robot with a special gripper

- Reassessment of the situation after each gripping process

Technological depth instead of pure mechanisation

What is remarkable is not so much the individual components as the interaction between the systems. The camera, evaluation software, robot kinematics and gripper are not simply added together as purchased parts, but are integral components of a complete solution. Vision-Tec consistently pursues the approach of bundling all core competencies in-house – from development and commissioning to service. This depth is crucial because empties logistics is a niche market with a high degree of variation. Standard solutions from palletising or depalletising technology can hardly be transferred here. The direct coupling of 3D vision and articulated arm robots for unsorted empties is therefore considered a unique selling point.

Significance for reusable containers, occupational safety and economic efficiency

Automated empty container sorting has an impact on several levels. It relieves employees of heavy, repetitive work, thereby improving ergonomics and occupational safety. At the same time, it increases throughput and creates predictable processes at a point that was previously heavily dependent on personnel deployment. This results in a strategic advantage for operators of large return locations. The more stable the flow of empties, the better downstream processes such as washing, sorting and filling can be synchronised. This process stability is becoming increasingly relevant, especially in the reusable sector, where efficiency and circulation speed are crucial.

A specialised market with clear prospects

Vision-Tec has been active in the market since 2011 and has deliberately focused on this narrowly defined segment. With around 100 employees, operations throughout Europe and an additional presence in South America, the company serves a market that appears small but is gaining in structural importance. The increasing automation of the beverage industry does not end at the filling line – it is increasingly affecting upstream and downstream processes. Automated empties sorting is a prime example of how digitalisation and robotics create added value where traditional technology reaches its limits. For Vision-Tec, this focus is not a marginal issue, but the result of a clear technological decision: not to simplify complex reality, but to make it manageable.