Compressed air is one of the central production media in many branches of industry. Particularly in the manufacture of food, beverages, pharmaceuticals or electronic components, its quality has a direct impact on product safety and process stability.

Even the smallest impurities can render entire batches unusable. Against this backdrop, oil-free compressed air is becoming increasingly important – not as a marketing promise, but as a technical necessity for demanding applications. While classic compressed air systems often rely on oil-lubricated compression, modern concepts take a different approach. They consistently separate the generation of compressed air from all potential sources of contamination. The goal is to achieve air quality that can be used in sensitive production environments without any subsequent compromises. Trade fairs for the process and food industries in particular show that this topic has long since transcended individual industries.

In addition to pure air quality, energy consumption is also becoming a greater focus. Compressed air is considered one of the most expensive forms of energy in industry. Inefficient systems cause high operating costs and have a negative impact on the carbon footprint. Accordingly, there is increasing pressure on manufacturers to develop solutions that achieve both maximum purity and minimum energy losses. A key element of modern systems is demand-based control of the compressors. Frequency-controlled drives make it possible to adjust the output precisely to the actual demand. Instead of running continuously, the systems respond flexibly to load fluctuations. This not only reduces power consumption, but also reduces component wear. In practice, this means longer maintenance intervals and higher system availability.

Oil-free screw compressors place high demands on design and manufacturing. Since no lubricating oil is used in the compression process, materials, coatings and manufacturing tolerances must be coordinated with particular precision. At the same time, efficiency must not be compromised, otherwise the energy advantage is lost. Typical areas of application for such systems are industries with extremely high quality requirements for compressed air:

However, an oil-free compressor alone is not enough. Only in combination with downstream compressed air treatment can a system be created that permanently meets the required quality classes. Drying, filtration and monitoring are integral parts of modern plant concepts. They ensure that moisture, particles and other contaminants are reliably removed before the compressed air enters the process. This holistic approach is becoming increasingly important as production plants become more and more complex. Operators do not expect individual components, but rather coordinated systems that can be integrated into existing structures and deliver stable results over the long term.

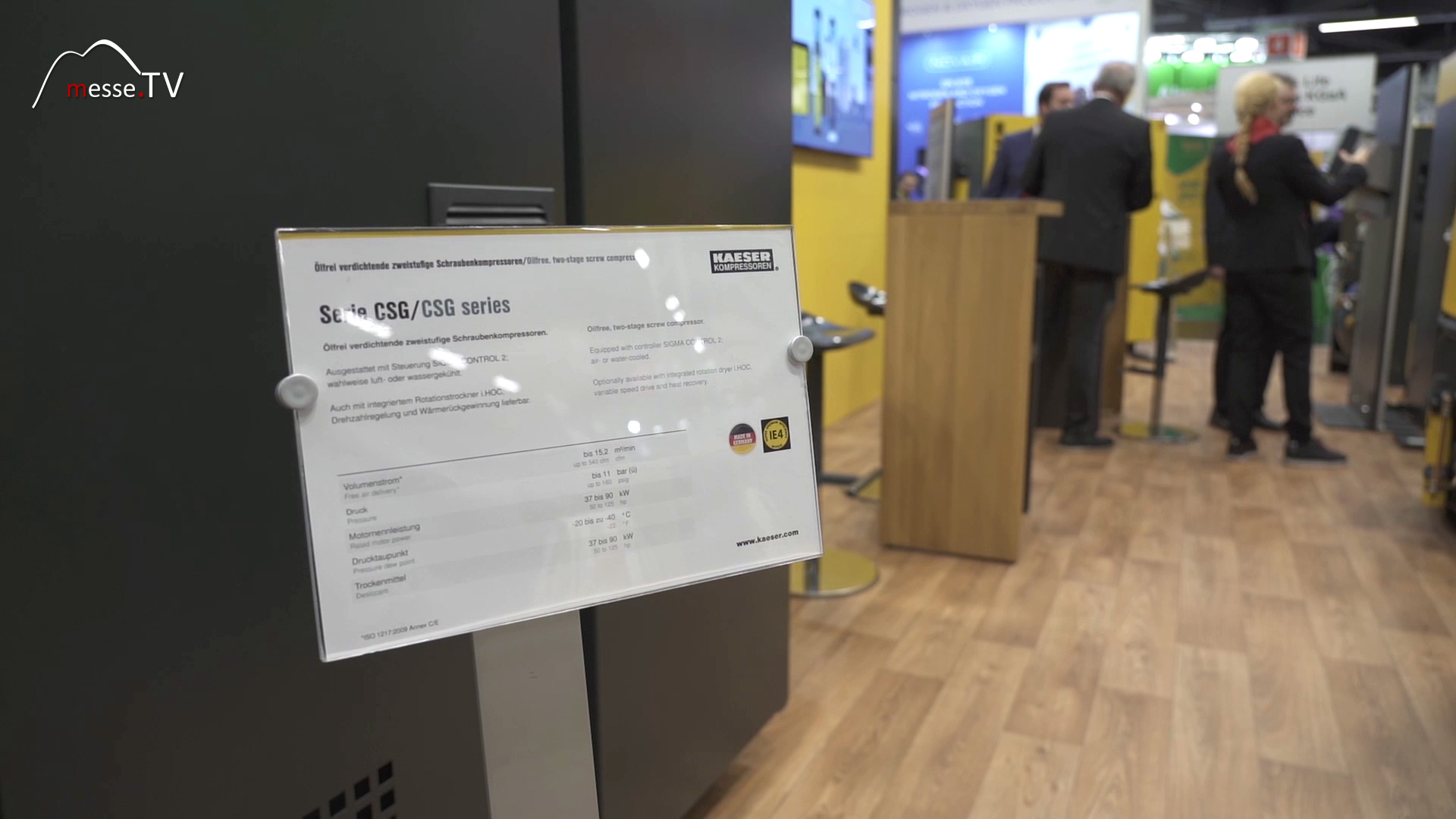

One company that has been pursuing this approach for decades is Kaeser. The medium-sized manufacturer based in Upper Franconia develops and produces its compressors exclusively in Germany. Its international presence is not the result of outsourced production, but rather a dense network of sales and service units located where industrial production takes place. The focus is on rotary screw compressors, supplemented by reciprocating compressors and comprehensive compressed air treatment solutions. Since the company was founded, product development has been guided by a central theme: more compressed air with less energy. This claim is particularly reflected in oil-free rotary screw compressors, which are specially designed for industries with high purity requirements. The system on display operates completely oil-free and is equipped with a frequency-controlled drive. The combination of oil-free compression and variable speed control aims to maintain both air quality and energy efficiency at a consistently high level. This design was developed as a proprietary solution tailored to applications where compromises are unacceptable.

The development of compressed air technology is exemplary of the transformation in industrial production. Efficiency, sustainability and process reliability are no longer separate goals, but are intertwined. Oil-free systems show that technical innovations not only meet regulatory requirements, but can also offer economic advantages. With rising quality standards in industry, there is a growing need for solutions that work reliably in the long term while reducing energy consumption. Compressed air is thus increasingly seen as a strategic factor – not merely as a secondary supply, but as an essential component of modern production concepts.