The Nano HCS can filler is aimed at companies that want to enter the can filling market for the first time and are looking for a compact, technically sophisticated solution. The focus is on small production volumes, flexible application options, and a manageable investment budget. This is exactly where the system comes in, which is just as suitable for small breweries as it is for other beverage manufacturers who want to tap into new packaging channels.

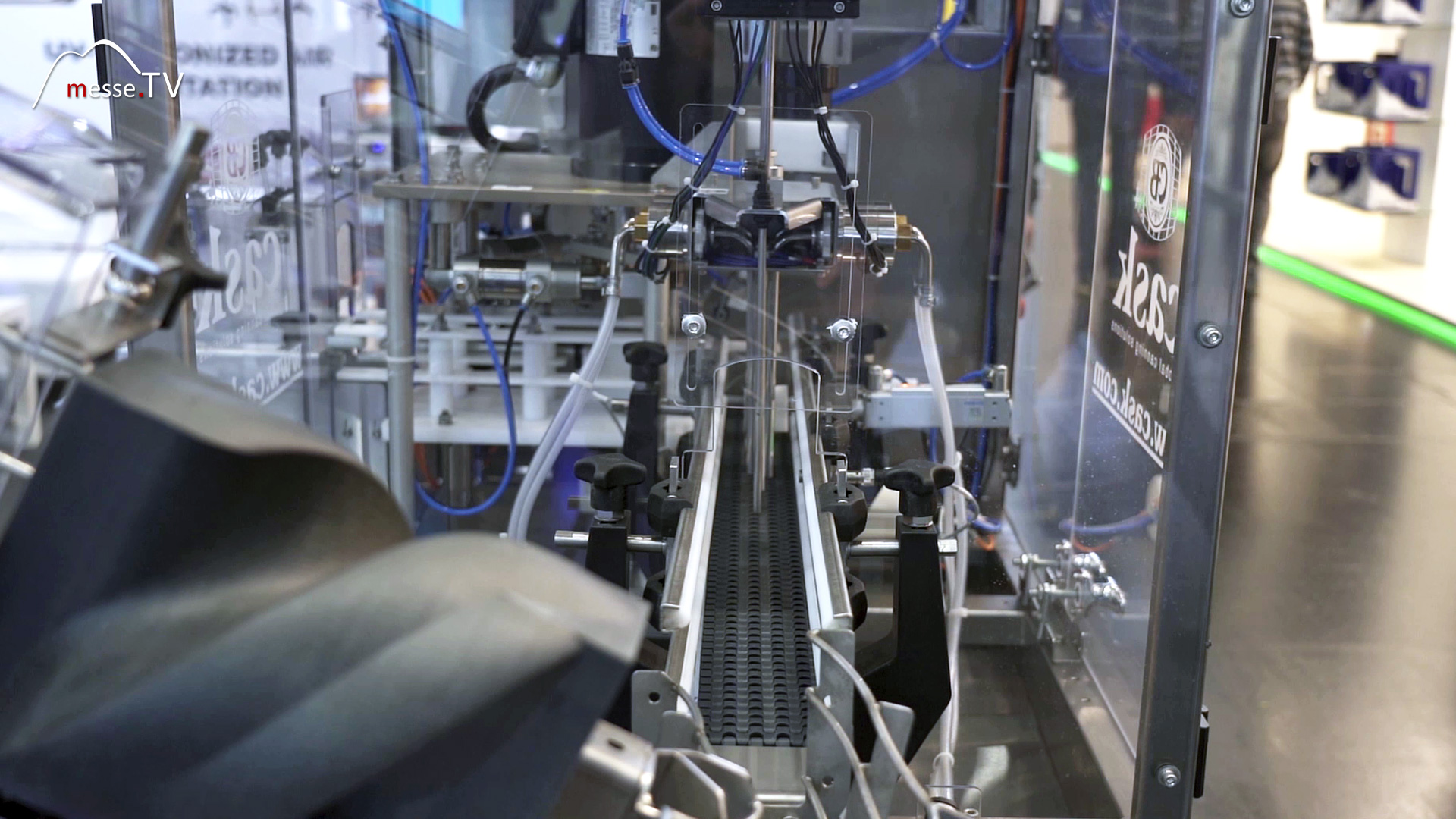

The Nano HCS can filler is designed to follow a clearly structured process. The empty cans are loaded manually and first cleaned by an integrated rotary washer. They are then filled before being sealed directly. At the end of the line, they are pushed out to the rear, where in many companies a labeling machine is already connected. This allows the filling process to be integrated into existing production processes without complex extensions. The system is deliberately designed for ease of use. The individual process steps are clearly separated from each other, making the process easy to understand even for companies without extensive filling experience. This reduced, functional approach is particularly crucial for companies in the start-up phase.

Even though breweries represent the core market, the Nano HCS can filler is not exclusively designed for beer. Other beverages that benefit from can packaging can also be filled. These include non-alcoholic beverages, mixed drinks, and functional drinks. Cans offer advantages in terms of shelf life, transport, and storage, without the need for high investments in complex bottle cleaning systems. The machine is particularly suitable for companies that want to respond flexibly to market requirements and fill different products in smaller batches. It thus supports business models that focus on diversity rather than mass production.

The trend toward cans has been established in North America for years and is now also gaining importance in Europe. A key factor is rising glass prices and high energy costs in glass production. Added to this are logistical aspects: aluminum cans are lighter, more space-saving, and easier to transport than glass bottles. Another point is recyclability. Aluminum can be melted down and reused many times without any loss of quality. This is a relevant aspect for companies that are concerned with sustainable packaging concepts. At the same time, there is no need for bottle washers, which are essential for reusable bottles and represent a considerable financial hurdle, especially for small breweries.

For newly established small breweries or beverage manufacturers in particular, can filling offers a pragmatic entry into the market. The Nano HCS can filler addresses several typical challenges at once:

CASK Canning originates from Canada and is based in Calgary. The company began developing small brewing systems in the 1980s. At the beginning of the 2000s, a gap in the market was identified: there were hardly any solutions for small can filling systems, even though craft breweries in particular were showing increasing interest in cans. This led to the development of the first compact can filler for small businesses. Today, the Nano HCS can filler builds on this development. It is the result of many years of experience in dealing with the requirements of small producers and reflects the change in the beverage packaging market. CASK Canning clearly positions itself as a provider of practical technology for businesses that produce on a small scale rather than industrially.

The choice of filling technology is a strategic decision for small beverage manufacturers. It influences production costs, logistics, brand image, and scalability. The Nano HCS can filler offers a solution that is deliberately designed not for maximum performance, but for cost-effectiveness and adaptability. For many companies, it is a first step into can filling without making a long-term commitment or taking on high financial risks. This makes the system a good fit for a market that is increasingly characterized by diversity, short product cycles, and experimental concepts.