Digital systems have been finding their way into areas where processes were long considered purely mechanical. The dispensing of beverages is one such area. In bars, restaurants, and at events, it is not only the product itself that determines quality and profitability, but also the technology behind it.

Temperature, pressure, flow, and hygiene determine whether beer is dispensed consistently or whether losses occur that often go unnoticed in everyday life. This is precisely where the development of a networked dispensing system comes in, combining classic dispensing technology with sensor technology and data analysis.

Behind this development is DSI Micromatic Getränkearmaturen, a merger of several specialized companies. The group combines the expertise of VINSERVICE, TAPRITE from the USA, and, most recently, MICRO MATIC. The Hamm site focuses on fittings, dispensing heads, and taps, while other areas of the group cover dispensing columns and pressure reducers. This bundling is not only relevant from an organizational perspective, but also forms the basis for systems that work across different hardware.

At the heart of the technical solution is an installation in which the tap head is no longer just a mechanical connecting element. It incorporates several sensors that record key parameters. These include the flow of the beverage, the applied gas pressure, and the reading of information via NFC technology using an antenna built into the fitting. This data is not evaluated locally, but is transmitted to a gateway via a wired connection. The gateway acts as a collection point. It can process several lines in parallel and also integrates the taps. These are battery-powered and communicate via Bluetooth. Among other things, the temperature directly at the outlet nozzle and the status of the flow are recorded here. The combination of tap head, tap, and gateway thus forms a closed system that records all relevant conditions during operation.

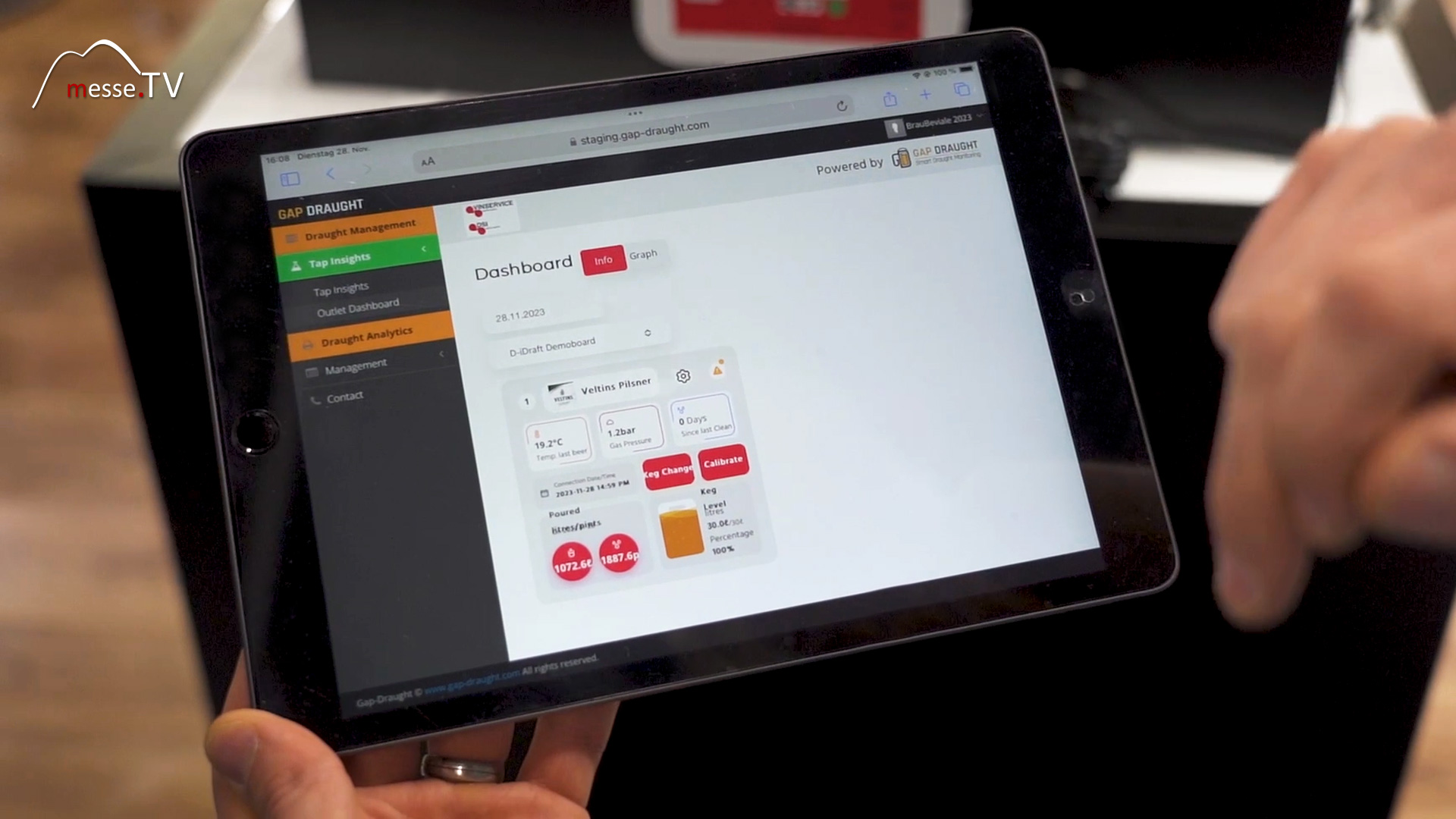

The collected data does not remain in the basement or behind the bar. It is transferred to a cloud environment via Wi-Fi, Ethernet, or an integrated mobile connection. There, it can be processed differently depending on the user group. A compact dashboard is available for on-site staff, displaying current temperatures, pressure values, and fill levels. Deviations from defined limit values are reported automatically. This opens up a different perspective for breweries. They receive aggregated information about dispensing quantities, time trends, and regional differences. This reveals which products are popular at what times and where there is room for optimization. The technology deliberately remains in the background, with the added value coming from transparency.

Digital dispensing is not intended as a gimmick, but as a tool for everyday use. The data collected enables intervention before quality problems arise. At the same time, processes can be standardized without having to monitor each location individually.

This approach is particularly evident where many dispensing points are operated simultaneously. Breweries have a strong interest in ensuring that their products are dispensed correctly. Dispensing at too high a temperature, incorrect pressure, or unplanned downtime have a direct impact on perception and sales. The NFC technology integrated into the fitting makes it possible to clearly assign information to a specific system. This is particularly relevant for supraregional evaluations. At the same time, the system remains manageable for the hospitality industry. The installation is based on familiar structures for dispensing system installation. No complex conversions are necessary; rather, the digital level complements the existing technology.

Serving drinks remains a craft. The tap, glass, and product continue to determine the moment at the bar. What is new is that this moment can now be measured. Data does not replace expertise, it supports it. DSI Micromatic Getränkearmaturen consciously positions itself in this area of tension: as a provider of infrastructure that does not automate the serving of drinks, but makes it traceable. This makes it clear that digitalization in the beverage sector does not necessarily have to be accompanied by radical changes. It is often sufficient to expand existing technology so that it meets the requirements of modern business management. Digital dispensing shows how classic dispensing systems can be converted into networked systems without losing their character.