The energy transition in the heating sector is often discussed from the perspective of residential buildings. However, in commercial and municipal environments in particular, the question of reliable, powerful and at the same time economically viable solutions arises in a different way.

Biomass plants play a central role here, especially when waste materials that are produced during operation can be used. This is exactly where specialised manufacturers come in, thinking of heating technology, fuel processing and conveyor technology as a complete system.

Heizomat is a family-run manufacturer based in the Franconian Lake District and sees itself as a company with regional roots and its own production facilities. A characteristic feature is the high level of vertical integration, which extends to almost all product areas. Instead of purchasing components and simply integrating them, key components are developed and manufactured in-house. This applies to both boiler technology and the upstream systems for fuel processing and feeding. Its claim to be a full-range supplier in the field of wood chip heating is evident in the fact that the process does not begin with the boiler. Rather, the entire value chain is taken into account – from the shredding of the wood to its discharge and conveyance to combustion and ash disposal.

A key unique selling point is the specialisation in problematic fuels. While many systems are designed for classic, homogeneous wood chip material, this concept is specifically aimed at users who work with residual wood, waste products or shredded pallets. Landscape maintenance material, treetop wood and heterogeneous wood chip qualities are also part of the typical range of applications. This approach consistently embraces the concept of the circular economy. Waste wood remains on site and is not disposed of, but used to generate energy. The added value thus remains with the user and is directly converted into heat.

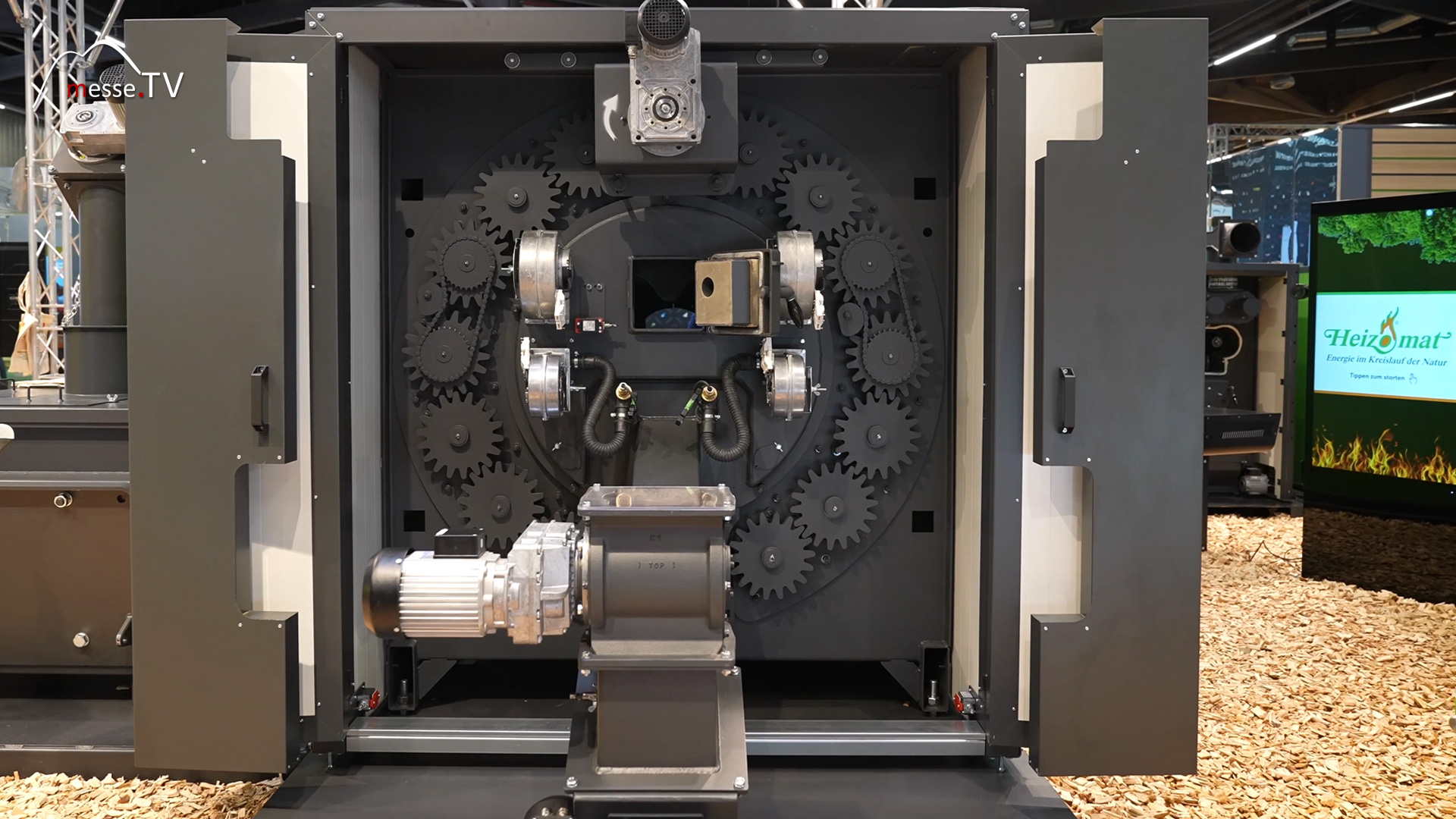

The portfolio includes proprietary chippers covering different performance ranges. These range from smaller solutions to large-scale systems designed for truck superstructures or as stationary installations. Particularly noteworthy are special pallet chippers that are specifically designed for the recycling of waste wood and industrial residues. This integration of shredding technology ensures that fuel quality and heating system are optimally matched. The customer does not receive an isolated product, but a comprehensive system that can be designed for their individual fuels.

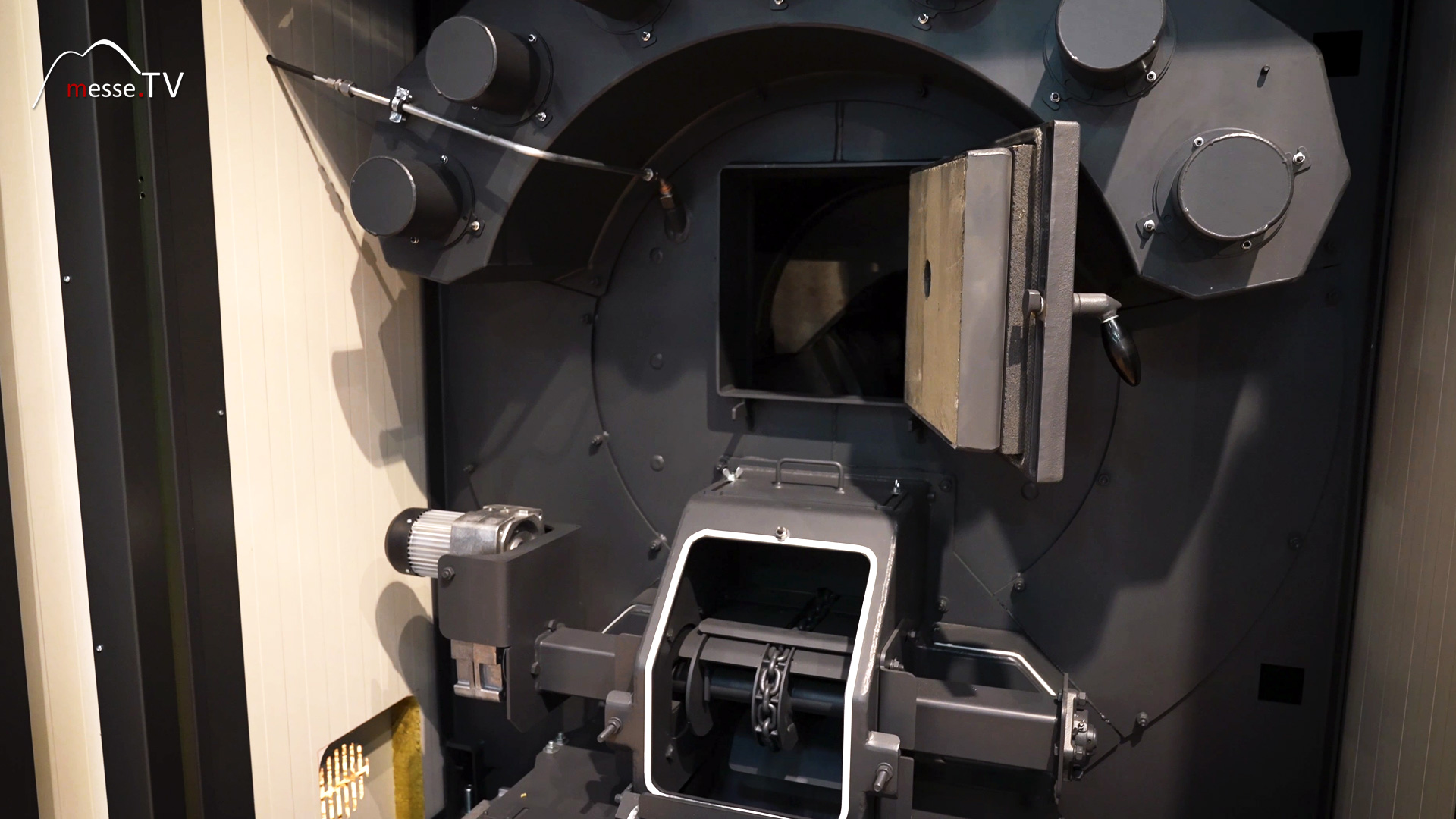

The presentation focuses on a 300 kW RHK waste wood boiler. This boiler is characterised by its solid construction, which is designed for durability and operational reliability. Despite its robustness, it uses modern control technology that enables app-based control, among other things. Remote access, monitoring and adjustments during operation are therefore standard features. A key design feature is the horizontal combustion chamber, which is completely enclosed by water. This design requires a correspondingly long combustion chamber, but offers decisive advantages when dealing with difficult fuels. The larger combustion zone allows even low-quality or highly variable wood chip qualities to be burned evenly without causing instability in performance.

In contrast to classic designs, the system does not use clapper or tilting grates. Instead, a circulating ash chain is used, which is functionally similar to a scraper floor from agricultural technology. This solution is extremely robust and ensures continuous ash discharge. The result is very trouble-free operation, even with demanding fuels. The ash is automatically removed from the boiler and discharged into appropriate containers, which reduces maintenance and facilitates continuous operation.

Different discharge systems are available depending on the size of the plant and fuel storage. In addition to milling solutions, various types of push floors are also available. This allows both small and very large bunkers to be reliably connected. This flexibility is particularly relevant for commercial users, where space, fuel consumption and logistics can vary greatly. The system can be individually adapted to the conditions on site without having to make any fundamental compromises in terms of operational safety.

In addition to classic installation in buildings, mobile solutions are also available. The boiler is housed in a container, enabling outputs up to the high three-digit kilowatt range. The advantage is obvious: there is no need to build a separate boiler house or carry out complex planning for the building envelope and infrastructure. This option can offer economic advantages and significantly reduce planning costs, particularly for temporary applications or for supplying small heating networks.

The performance spectrum ranges from systems for small buildings to large-scale systems for district heating and heat contracting. While smaller outputs tend to be used in agricultural or commercial environments, there is a clear focus on medium-sized companies and small heating networks. Large-scale systems with outputs in the megawatt range are aimed at municipal projects and industrial applications where constant heat consumption and long-term operational reliability are crucial.

In the medium output range, the investment costs are significantly higher than for conventional heating systems, depending on the size. For a 300 kW plant, the rough cost framework is in the upper five-digit range, depending on equipment, discharge and peripherals. The decisive factor here is not so much the pure purchase price as the long-term economic efficiency achieved through low-cost fuels and high availability. Especially for businesses with their own waste wood or a continuous supply of biomass, this creates an overall energy concept that reduces costs, avoids disposal and ensures security of supply.