Biomass has been considered a reliable pillar of renewable heat supply for decades. While public debate often focuses on heat pumps and electricity, a technical field is developing in parallel that plays a central role, particularly in rural areas, in renovations and in local heating networks. The trade fair clearly shows how much biomass boilers have changed technically – they are now more compact, cleaner, more networked and more flexible than they were just a few years ago.

Fröling has been exclusively involved in biomass boilers and the associated storage technology since the early 1960s. The focus is consistently on wood as an energy source – in the form of pellets, logs or wood chips. Development and manufacturing take place in Upper Austria and Germany, where the storage technology in particular is developed. This close integration of boiler and buffer systems continues to shape the technical orientation of the company to this day.

The SP Dual Compact is the centrepiece of the trade fair presentation. The device combines pellet and log operation in a very small space. Two combustion principles work in one system on a floor space of around one square metre, supplemented by an integrated fine dust filter. The boiler is thus aimed at a classic field of application: single-family and two-family houses where space is limited but where the desire for flexibility in terms of fuel remains high. Technically, operation begins in pellet mode. Pellets are sucked in from a storage container, conveyed to an internal container and, when required, fed onto a grate via a chute. This is where the electric ignition takes place. The resulting flame can then be used to automatically ignite logs in the adjacent combustion chamber. The switch between operating modes takes place without manual intervention on the boiler.

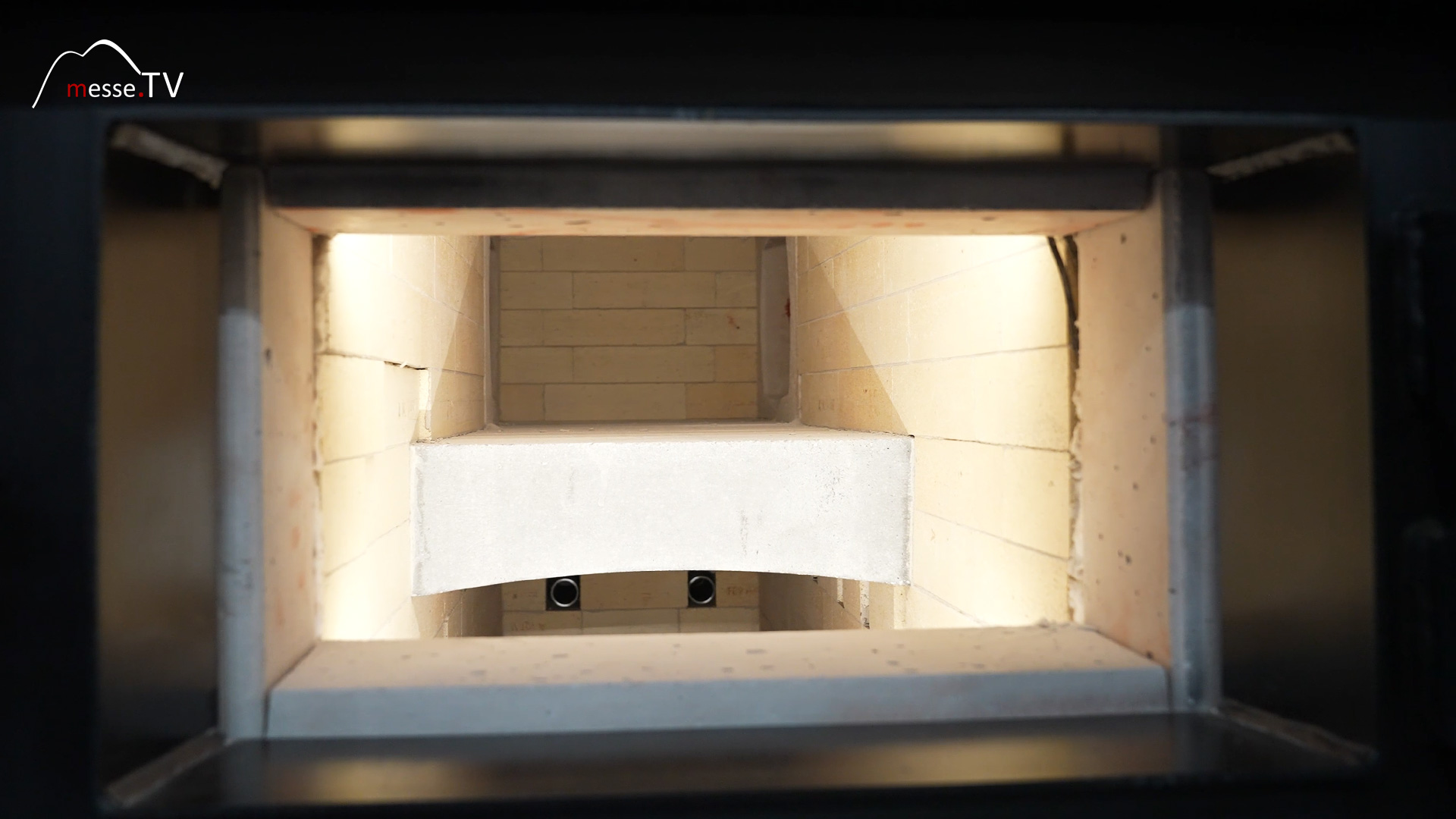

A key feature of the SP Dual Compact is its downward combustion. The flame is drawn downwards by a draught, flows through the heat exchanger and then passes through the integrated filter before the exhaust gases are fed into the chimney. This combustion control ensures even heat transfer and helps to reduce emissions. With outputs ranging from around 15 to 20 kW, the boiler covers the typical heating requirements of classic residential buildings. This output class plays a decisive role, especially in existing buildings where biomass is deliberately used as an alternative to oil or gas.

In addition to combustion technology, control technology is becoming increasingly important. The SP Dual Compact has a modern touch control panel directly on the device. This interface can be mirrored completely on mobile devices. Settings for heating circuits, temperatures or operating modes can thus be made from a smartphone or tablet, regardless of where you are in the building. The system is transparent during operation: boiler temperature, exhaust gas temperature and heating circuit parameters can be called up at any time. Control is infinitely variable, for example via a slider for the desired room temperature. The only requirement for this is that the boiler is integrated into the local network.

Storage technology is closely linked to boiler operation. Buffer storage tanks with internal sensor strips determine when the boiler starts or switches off. Once the set target temperature in the storage tank is reached, the boiler automatically shuts down. This coordination is particularly important in log wood systems, as the entire energy of a load is transferred to the storage tank.

In everyday life, this means that it is usually sufficient to feed the log boiler once a day to reliably supply a residential building. Only when outside temperatures are extremely low does demand increase. In the summer months, the boiler can even remain completely switched off if solar thermal energy is available, as hot water is provided by solar yields.

Beyond the single-family home sector, biomass boilers play an important role in local heating networks. Wood chip boilers with significantly larger dimensions and outputs in the high three-digit kilowatt range are on display. In such systems, wood chips are automatically conveyed to the grate, burned, and the resulting heat is fed into a local heating network via heat exchangers. These networks supply entire neighbourhoods rather than individual buildings. Depending on the design, pipe networks several kilometres long can be created to ensure sufficient load. Such concepts are specifically promoted politically, as they combine regional value creation with renewable heat.

The trade fair presentation shows the entire range of biomass heating systems – from compact hybrid boilers for residential buildings to powerful solutions for municipal heating networks. The technology has developed significantly: emissions are falling, operation is becoming more digital and systems can be combined more flexibly. Biomass thus remains a relevant component of the heating transition, especially where electrical solutions reach their limits or regional fuels are available. The decisive factor is not so much the individual technology as the interaction between the boiler, storage tank, control system and integration into overarching concepts. This is precisely where modern biomass systems come in today.