Komatsu PC220-LCi excavator: New machine generation with intelligent control 3.0

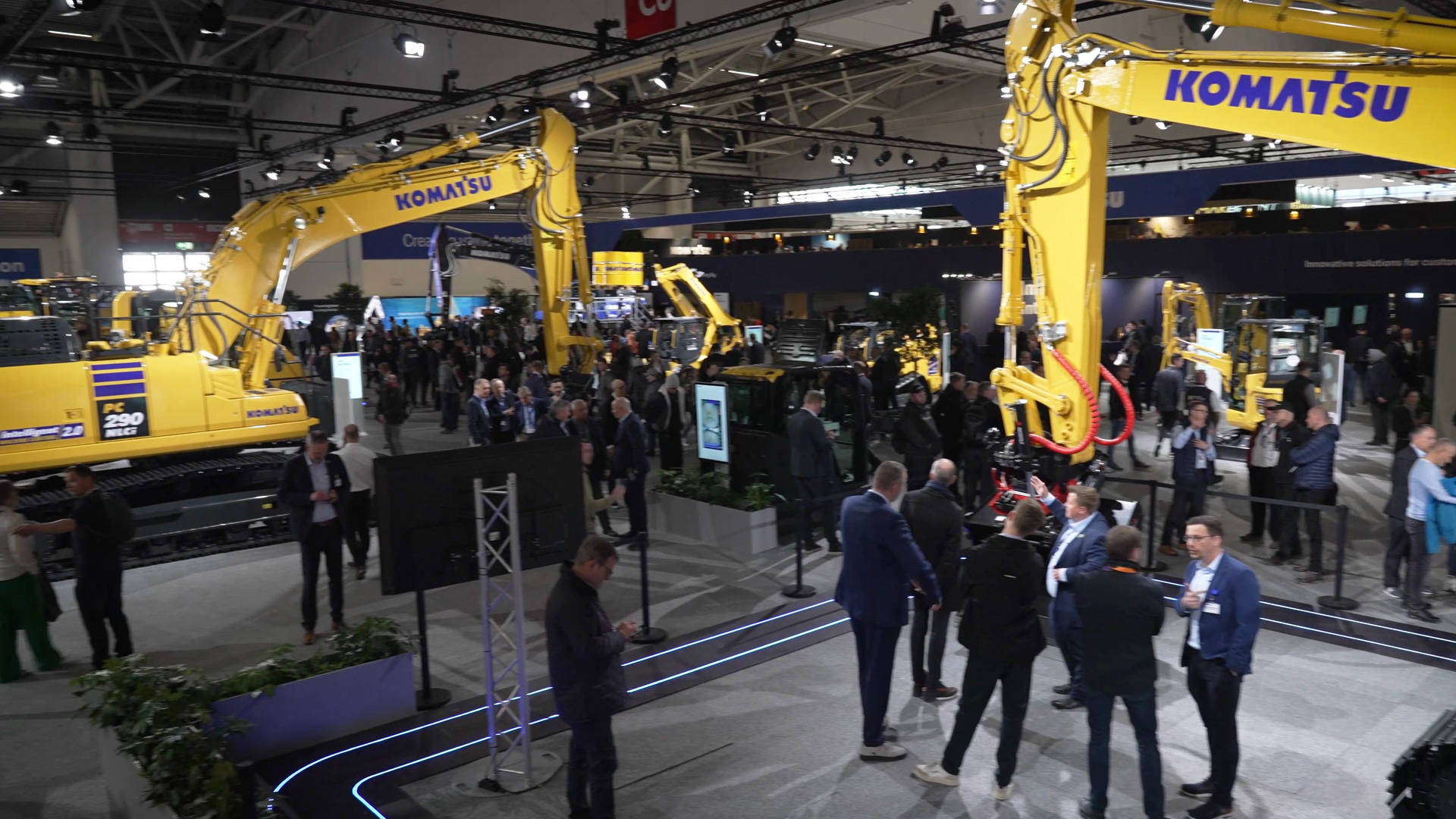

by A. Bergmeier - 2025-04-30The Komatsu PC220-LCi is a new crawler excavator and also a Komatsu excavator from a new generation of machines, which is being introduced with Intelligent Control 3.0. As a new model and new platform, the Komatsu PC220-LCi combines a completely redesigned machine architecture with automated assistance functions, precise sensor technology, and efficient hydraulics. The crawler excavator with intelligent control thus represents a clear technological leap forward in terms of ease of use, productivity, and digital construction site support.

With the PC220-LCi, Komatsu is introducing a completely newly developed excavator platform that combines technological innovation, comfort, and efficiency. The machine exemplifies the next step in intelligent machine control, complemented by a new cab design, revised hydraulics, and comprehensive digital assistance functions.

Completely new machine concept with third-generation intelligent control

According to Komatsu, the PC220-LCi is not just another step forward, but a completely new start in the field of intelligent machine control. Control 3.0 – iMC 3.0 – is at the heart of this concept. It significantly expands the range of functions and turns the excavator into a high-precision work tool. In combination with new sensors and digital assistance systems, it forms the technological basis for automated and individually customizable work processes.

One new feature is the 3D boundary control, which not only enables defined working areas to be maintained, but also increases safety when working on slopes. If, for example, the machine is traveling on an incline, protective mechanisms are activated to safeguard the operator and the machine. This function is integrated directly into the machine control system and does not require any additional modules to be retrofitted.

Improved productivity with reduced fuel consumption

A key development goal was to increase machine performance while reducing fuel consumption. According to Komatsu, both have been successfully achieved. The new P+ mode and the revised hydraulic system have reduced fuel consumption by 18% compared to the previous generation, while productivity has increased by 18%. This optimization is based, among other things, on a new, electronically controlled hydraulic system that intelligently adapts the pump output to the respective work process. The PC220-LCi has two high-performance hydraulic pumps that together deliver a flow rate of 504 liters per minute.

PC220-LCi crawler excavator cab: Operator-focused cab design with automotive character

A clearly visible improvement can be seen in the cab area. The new design is significantly more spacious – the floor space has been increased by 30% – and offers noticeably better visibility. Visibility has been improved by 50% in the lower right-hand area in particular, which has a direct impact on work safety and precision.

The cab is designed to make long working days as comfortable as possible. Ergonomically optimized controls, high-quality materials, and a high-performance driver's seat are standard features. Even details such as a luxury floor mat and a large parallel wiper for the windshield underscore the focus on automotive standards.

Komatsu emphasizes that the machine was designed from the operator's perspective: all controls are arranged for intuitive operation. Electronically programmable control levers allow individual assignment of preferred functions. The speed and positioning of attachments can also be freely defined and stored.

Automation and precise programming of work sequences

Komatsu has added another innovation to the PC220-LCi in the form of the “Auto-Swing” function. The operator can define excavation areas, truck heights, and dumping zones in advance. The machine then automatically takes over the entire swing operation—from bucket movement to unloading—at the touch of a button. This eliminates the need for manual intervention via the control levers.

Another practical feature is “Dig the Line.” This keeps the excavator exactly within the line defined in the design. This makes things a lot easier, especially on projects that require high precision or have limited tolerances.

The control system is also equipped with a payload measurement system that continuously records and documents the material quantities. This function is particularly helpful during loading operations, as it prevents overloading and ensures that trucks are utilized to their full capacity.

Factory-integrated sensors and flexible equipment

The PC220-LCi comes with extensive sensor technology as standard: IMU sensors are mounted on the boom and arm as standard. They continuously record the movement and position of the machine. Unlike retrofitted systems, all components are factory-calibrated and fully integrated into the control system.

Depending on requirements, you can choose between the standard PC220LC version and the fully equipped LCi version. Both variants are equipped with a 2D control system, payload scale, and optional iMC monitors. If you are looking for maximum automation, choose the LCi variant with extended functionality.

A tiltrotator can also be attached and is fully compatible with the 3.0 control system. This allows angles and rotations to be controlled digitally – for particularly flexible applications, such as trench digging or working in confined spaces.

Powerful drive, robust hydraulic package

At the heart of the machine is a 129 kW engine designed for demanding applications on construction sites. The combination of a powerful drive and the new hydraulic system enables fast yet precise movements, even during complex work cycles.

The hydraulic output of over 500 liters per minute is precisely controlled by a digital control system, which not only increases efficiency but also extends the service life of the components. In addition, the synchronization of the electronics and mechanics improves the response speed to operating commands.

Everything new: design, technology, and operating concept

Komatsu emphasizes that not a single element of the PC220-LCi has been carried over from its predecessor. The entire machine—from the design and interior to the control technology—has been redesigned from the ground up. The aim was to create a platform that is both technically and ergonomically future-proof.

Customer feedback at bauma 2025 has been correspondingly positive. Visitors particularly praised the new cab, which they said is currently unique on the market in terms of comfort, spaciousness, and technology. With the PC220-LCi, Komatsu is pursuing a clear goal: maximum productivity, maximum control precision, and a machine environment that is consistently people-oriented.