The self-loading concrete mixer is the best-selling machine in the Carmix range and enables concrete to be produced where it is needed - directly on the construction site. Especially in remote regions, where conventional supply solutions reach their limits, the system impresses with its independence, efficiency and precision.

The machine handles all steps of concrete production on site. It is constructed to be suitable for off-road use and designed to work reliably even under adverse conditions. Thanks to its self-loading capability, all the required aggregates such as sand, cement and water are picked up directly. Two integrated water tanks provide the necessary amount of water. This not only saves on transport routes, but also ensures flexibility in the construction process - especially where conventional mixing plants are logistically inaccessible or would incur high costs.

A well thought-out design feature of the self-loading concrete mixer is the cab positioned at the front. Unlike many competitors, this gives the driver a clear view of the loading unit and the terrain in front of him. This improved overview not only contributes to safe operation, but also to more efficient loading. At the same time, the lower seating position ensures comfortable handling - an advantage that should not be underestimated for long operations or on uneven terrain.

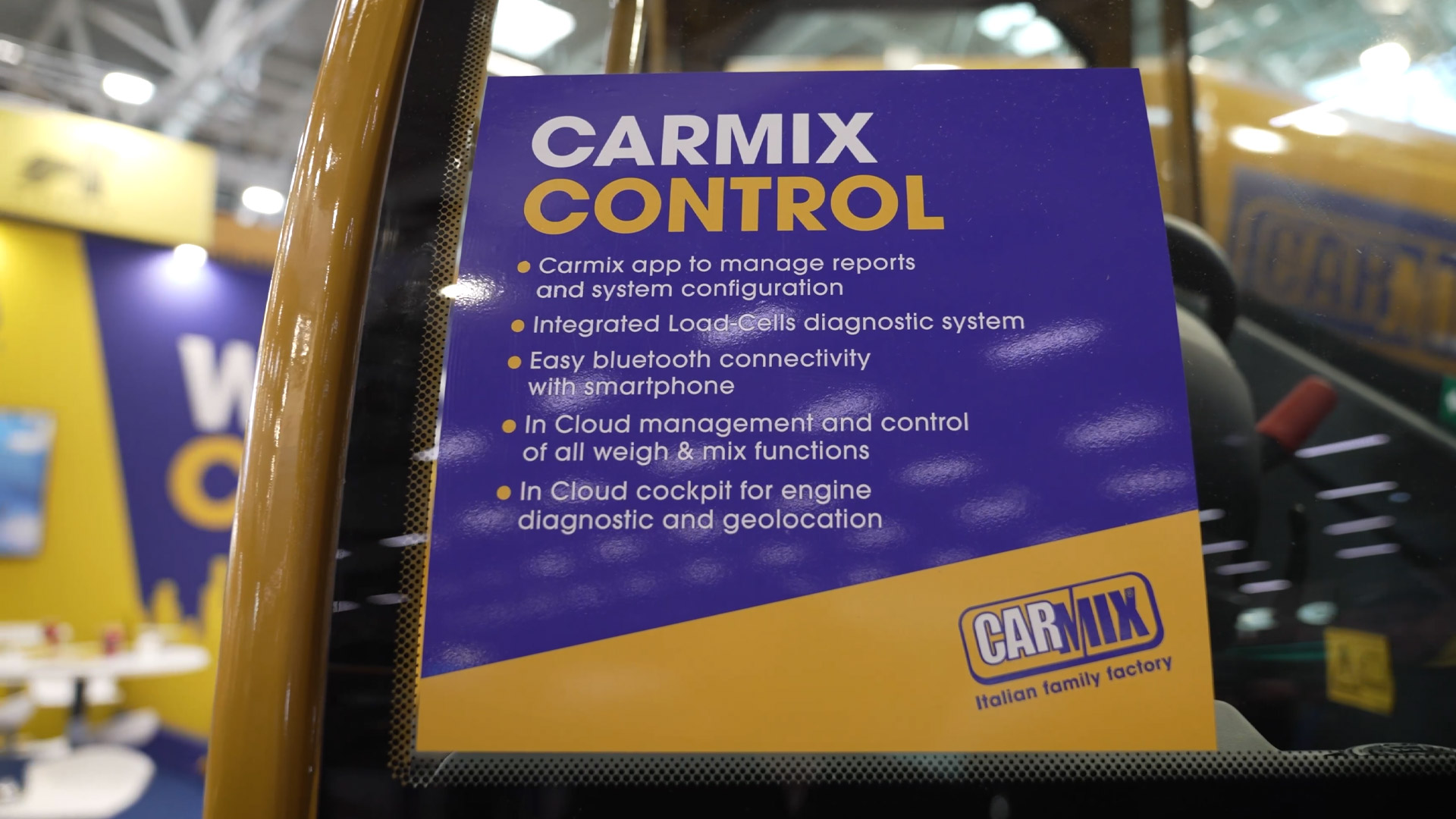

With the new electronic weighing system, Carmix provides a modern solution for the precise documentation of mixing processes. The system registers all components of the mix, stores them digitally and makes them available in the cloud. This allows not only the respective recipes to be traced, but also the work processes, receipts and maintenance intervals to be managed centrally.

This also includes daily machine checks and engine inspections. This creates a seamless, digital protocol that offers clear advantages in both technical and economic terms - for example with regard to verification obligations, quality management or the coordination of construction projects over long distances.

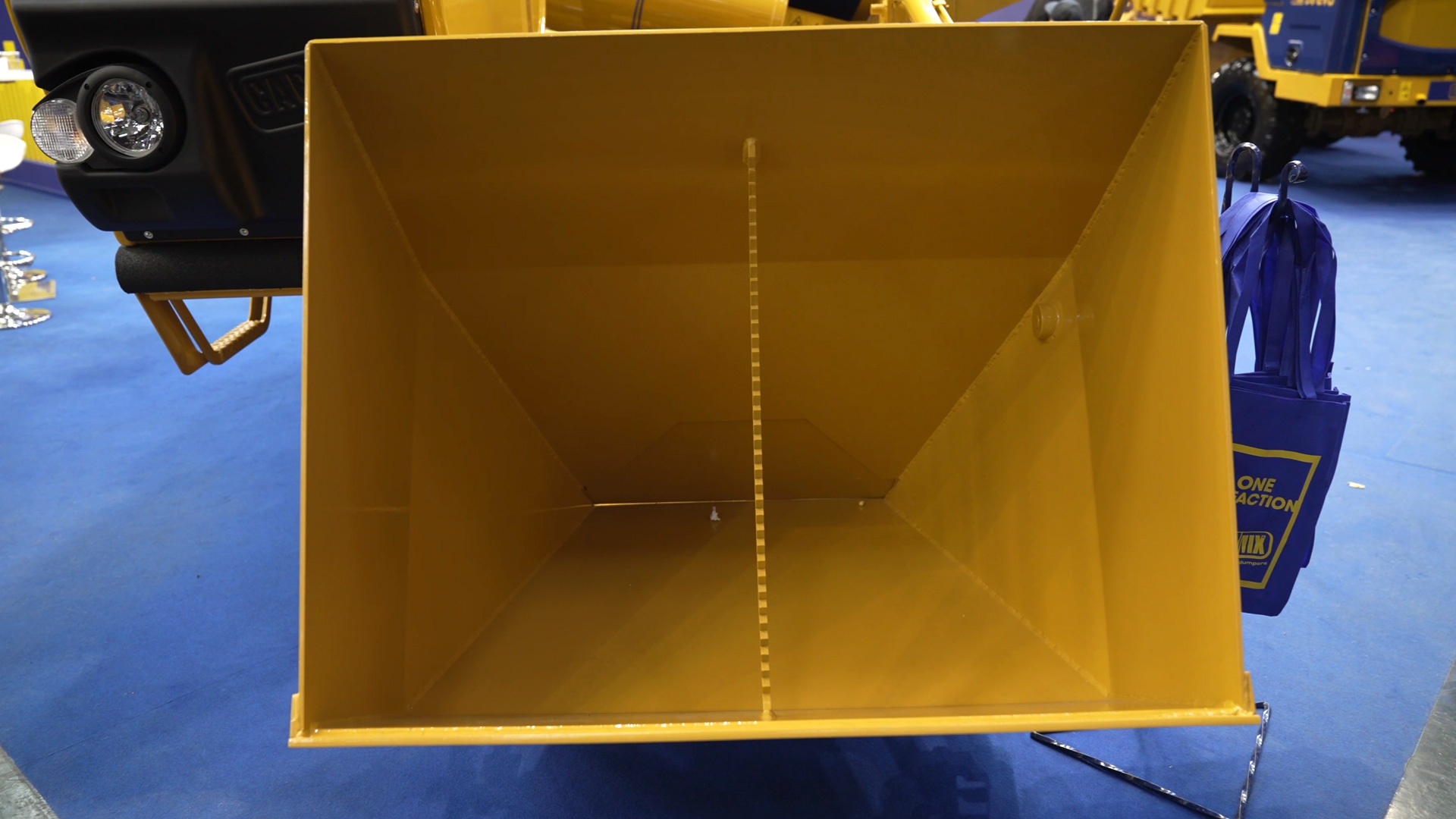

A key unique technical feature is the precise load cell system. Four load cells - two at the front and two at the rear under the drum - precisely record the weight of all components that enter the mixing drum. This ensures that every mix has the desired composition. Even the water is not just added, but actually weighed. The result: consistent mixing quality on a par with stationary systems - without the infrastructural effort. This makes work considerably easier, especially for larger construction projects in regions without fixed supply facilities.

Carmix produces at its headquarters near Venice and exports around 99% of its machines worldwide. Customers can be found in Africa, Asia, South America and many other regions. Each machine is adapted to the respective emissions regulations of the country of destination - for example, with engines that meet the Stage 3 or Stage 5 emissions standard. This flexibility enables the manufacturer to serve different markets without compromising on quality. The investment costs for such a machine range from around 120,000 to 150,000 euros, depending on the configuration and emission level.