Bobcat introduces the Bobcat E-Series mini excavators, a series that is ideally designed for landscaping and civil engineering and has been consistently tailored to practical use. Under the slogan “Bobcat E-Series: Compact mini excavators with a consistent focus on practicality,” the machines combine compact design, high transportability, and well-thought-out operator comfort. This positions the E-Series as a versatile solution for construction sites where maneuverability, performance, and everyday usability are equally important.

Bobcat presents a revised mini excavator product range in the 1.5-tonne class segment. The E16 to E20z models have been specifically developed for applications where compactness, transportability and operator comfort are equally important. The new generation builds on the proven line and at the same time sets new standards in ergonomics, safety and functionality.

A key feature of the new series is the larger-than-average cab. The entrance has been made wider, the seating position optimized and even tall people have sufficient room to move around inside.

Well thought-out arrangement of the controls, generous glass surfaces and an improved view of the attachment make it easier to work in confined spaces. The focus on the machine operator is particularly evident in the lateral field of vision and the view of the implement.

Despite the compact dimensions, the performance remains at a high level. The machines are equipped with powerful hydraulics and a high-torque drive, as you would expect from Bobcat. Special attention was paid to the undercarriage design: The retractable undercarriage enables a reduced machine width, which means that it can also be used on narrow construction sites, in courtyards or between building walls. The maneuverability of the mini excavator is further enhanced by the zero tail swing - the uppercarriage remains completely within the track guide, without any overhang. This also makes the models suitable for precise work directly on walls or in narrow construction gaps.

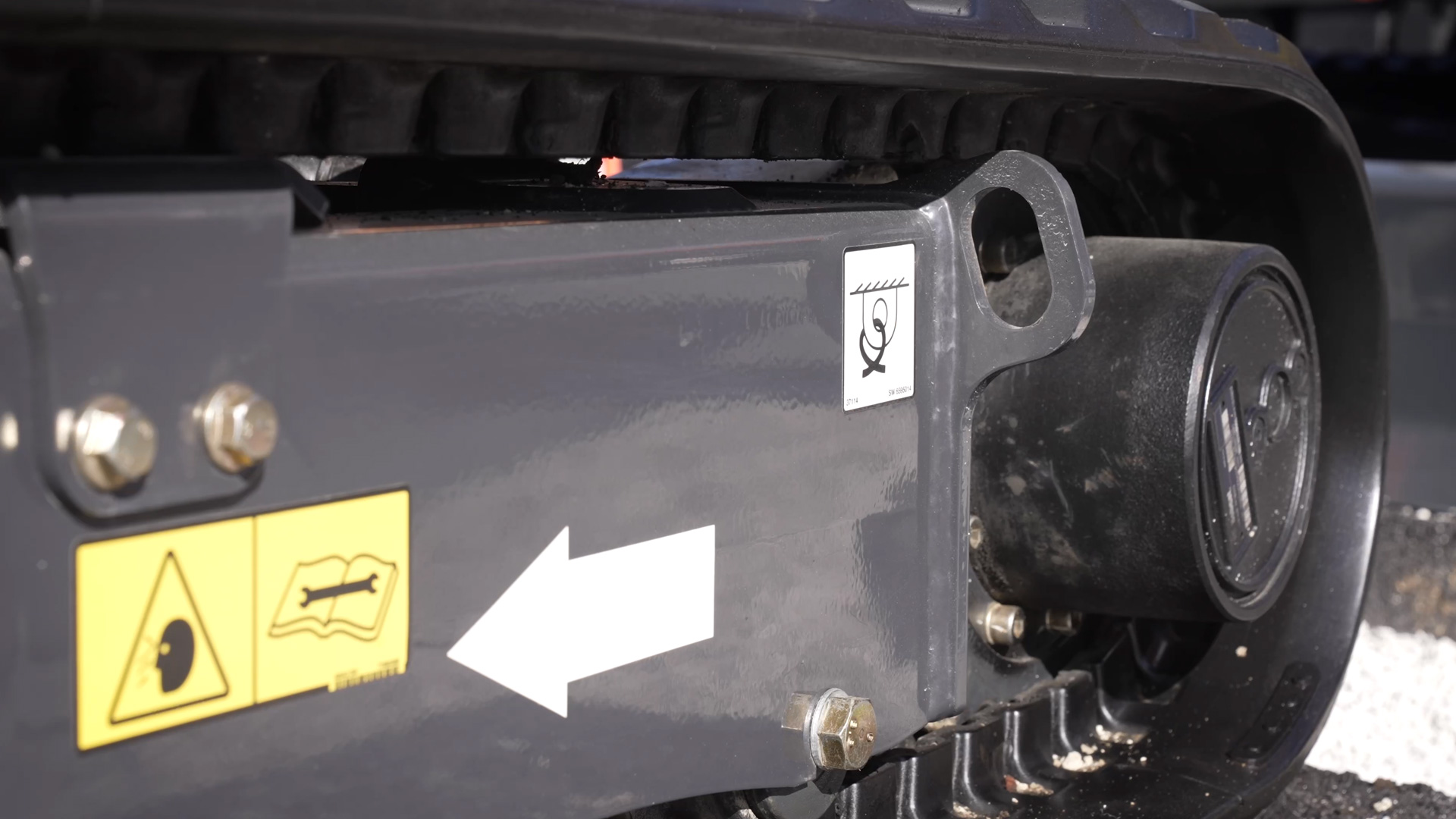

Depending on the configuration, the E-series machines remain under the two-ton mark. The E19 with cab weighs around 1.9 tons, with a long bucket arm around 30 kilograms more. These values allow it to be transported on a conventional trailer while complying with the permissible total weight for towing vehicles up to 3.5 tons. Lifting eyes and lashing points are integrated at the factory: For lifting over obstacles such as fences or for securing loads, both lifting eyes on the chassis and attachment options on the boom are available.

The product range is designed for a wide range of applications. Typical areas of application include gardening and landscaping, interior demolition and work in sewer and road construction. The machines offer the required balance of robustness and flexibility. In landscaping in particular, the narrow design in conjunction with the lifting points allows the machines to be moved by crane - for example on sites with restricted access. The robust track guidance and tight turning circle make the excavators a reliable tool, even on difficult surfaces.

The range of functions has been specifically expanded in the new model generation. Additional options such as piping and connections have been designed to meet today's requirements on the construction site - whether for operating attachments or connecting to external systems. The intuitive operability has been retained, supplemented by a revised safety concept. This includes reversing alarms, systems for detecting people in the work area and new solutions for obstacle detection in selected series.

The majority of the machines are manufactured within Europe. Proximity to the market enables Bobcat to react quickly to changing requirements. For example, the new generation of compact excavators has been specifically developed based on feedback from the field. The high availability of spare parts, short delivery routes and on-site technical support underline the company's claim not only to supply machines, but also to provide permanently functioning solutions for everyday construction work.