CAT road-rail excavator platform in track construction: powerful, modular and safe

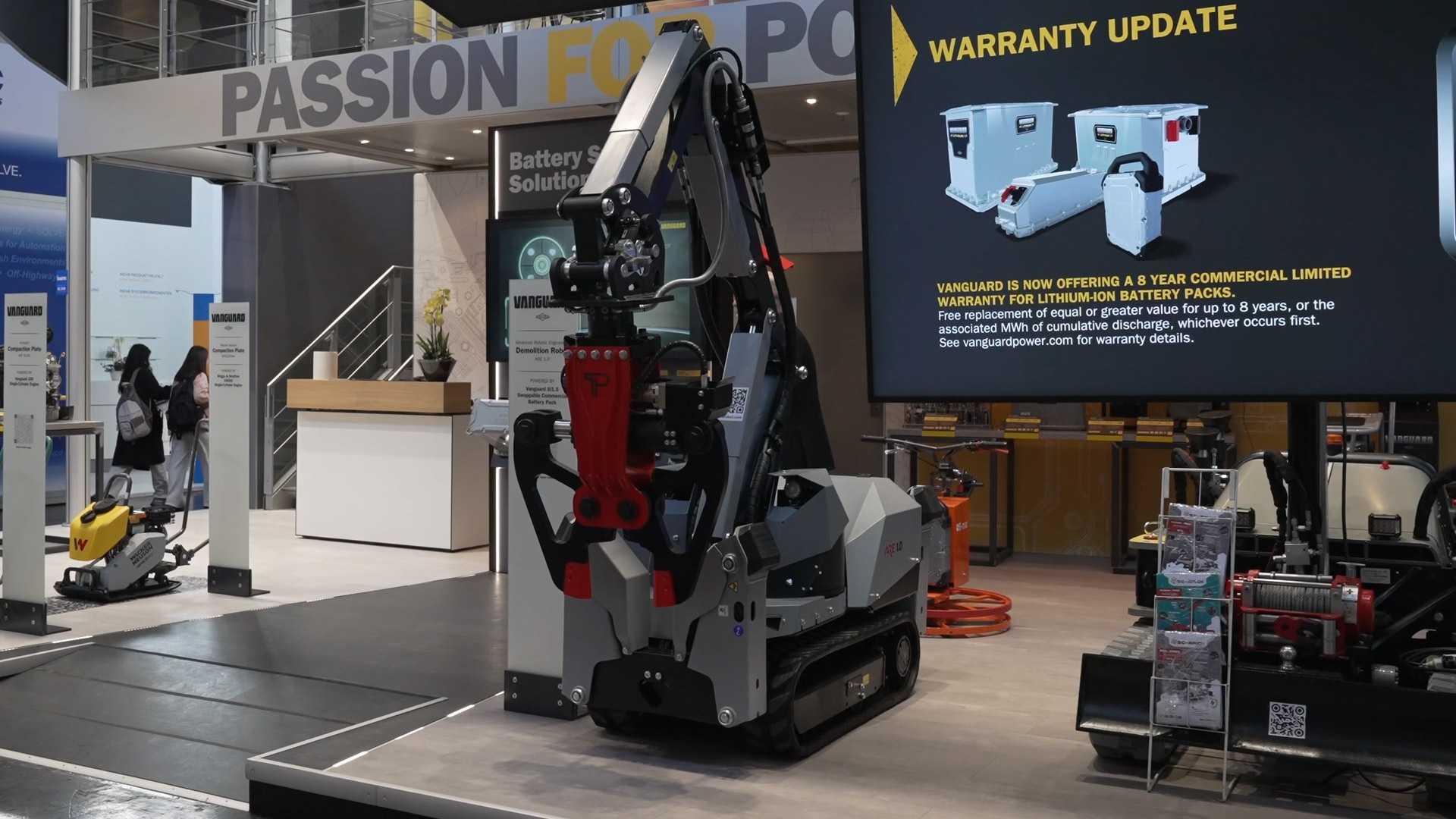

by B. Velonavy - 2025-04-08The road-rail excavator is an indispensable machine in modern track construction. The new platform on display offers a variable concept with selectable drive, optimized cab and a more powerful drive train for the first time. It was specially developed for the requirements of rail construction and is used on almost every track construction site.

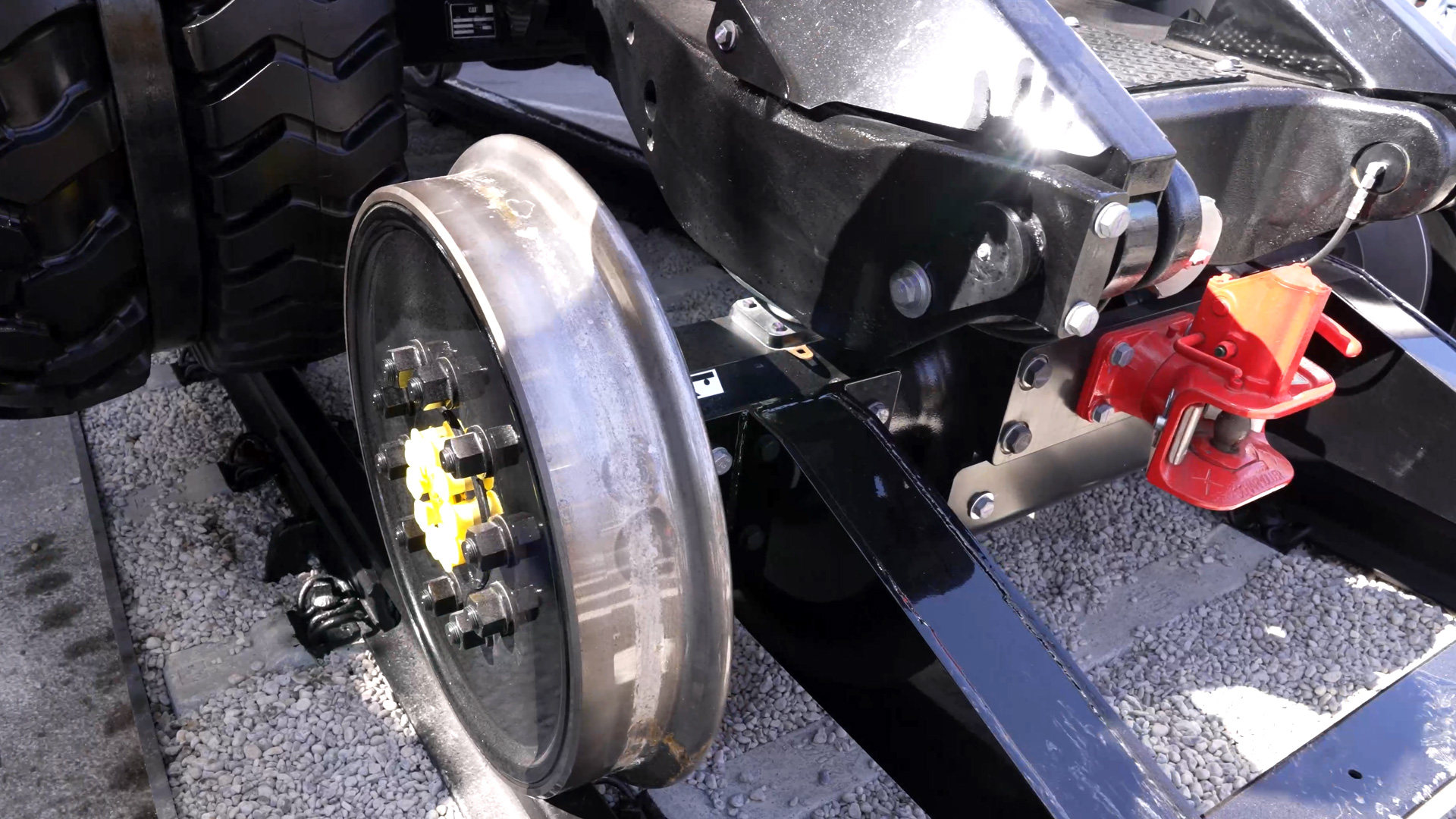

Operation via rubber wheels - rail wheels take over guidance and braking

The road-rail excavator runs either on the road or on rails. In rail operation, the machine in this version is driven exclusively by the rubber tires, which run directly on the rail. The rail wheels are not driven, but have brake disks - visibly integrated into the chassis. The drive via the tires ensures flexibility, while the braked rail wheels provide precise guidance.

Alternatively, the platform can also be configured with driven rail axles, whose solid construction indicates the built-in travel drive. This allows the excavator to adapt to different requirements on site - depending on the terrain, type of application or technical specifications.

Modular platform concept with configurable rear and drive system

The new platform is based on a basic concept that offers the operator various options. In addition to the choice of drive system - rubber wheel drive, rail wheel drive or a combination - the rear module can also be adapted as required. This allows the machine to be configured for a wide range of applications in infrastructure construction. The modular design not only saves costs during development, but also makes servicing, spare parts supply and conversions easier. This makes the platform a long-term solution for construction companies and rail service providers.

Powerful diesel engine with powerful hydraulics for implement use

The version presented here is equipped with a Caterpillar diesel engine with a displacement of 4.4 liters and 183 hp. The power generated is transferred to a high-performance hydraulic pump, which operates all hydraulic consumers - including the swing motor, the excavator arm and a wide range of attachments. The machine is therefore designed for heavy tools and intensive operations in the track area. Thanks to the combination of powerful drive and modular platform, it meets both general and specialized requirements in permanent way construction.

Cabin concept with a focus on ergonomics, overview and operating logic

The redesigned cab offers better visibility and a modernized lighting system that allows precise work even in poor lighting conditions. The operating logic has been significantly simplified: screens and controls are arranged so that all functions can be accessed directly via the joysticks.

The driver does not have to take his hands off the control unit during operation - a clear safety advantage during operation. The intuitive operation not only makes it easier to get started, but also increases productivity on the construction site.

Swivel lift limiter protects neighboring tracks and overhead lines

The lift swivel limit is a key safety feature, particularly in the rail infrastructure sector. It allows the definition of a precisely limited working area - both laterally and vertically. This reliably prevents the excavator arm from inadvertently swinging into a neighboring track or the overhead line.

This is particularly essential on electrified lines or where trains are running in parallel. The adjustment is made via the control system, which reliably maintains the defined working area. This function significantly increases safety for people, machines and infrastructure.