The efficiency of a heating system can be further increased with a condensing boiler. At Heim+Handwerk in Munich, we had a closer look at the pellet condensing boiler from ETA Heiztechnik and learned how modern condensing technology is also used in the field of regenerative heating systems.

Many operators are already familiar with the term condensing technology from the oil and gas sector. The aim is to utilize as much of the energy contained in the fuel as possible. This principle is also applied to pellet heating systems by using the energy contained in the exhaust gases in addition to the classic heat recovery. This technology plays a special role in new builds, where high efficiency requirements are combined with the use of renewable energies. The pellet condensing boiler covers precisely this segment and adds a further level of energy utilization to the classic pellet heating system.

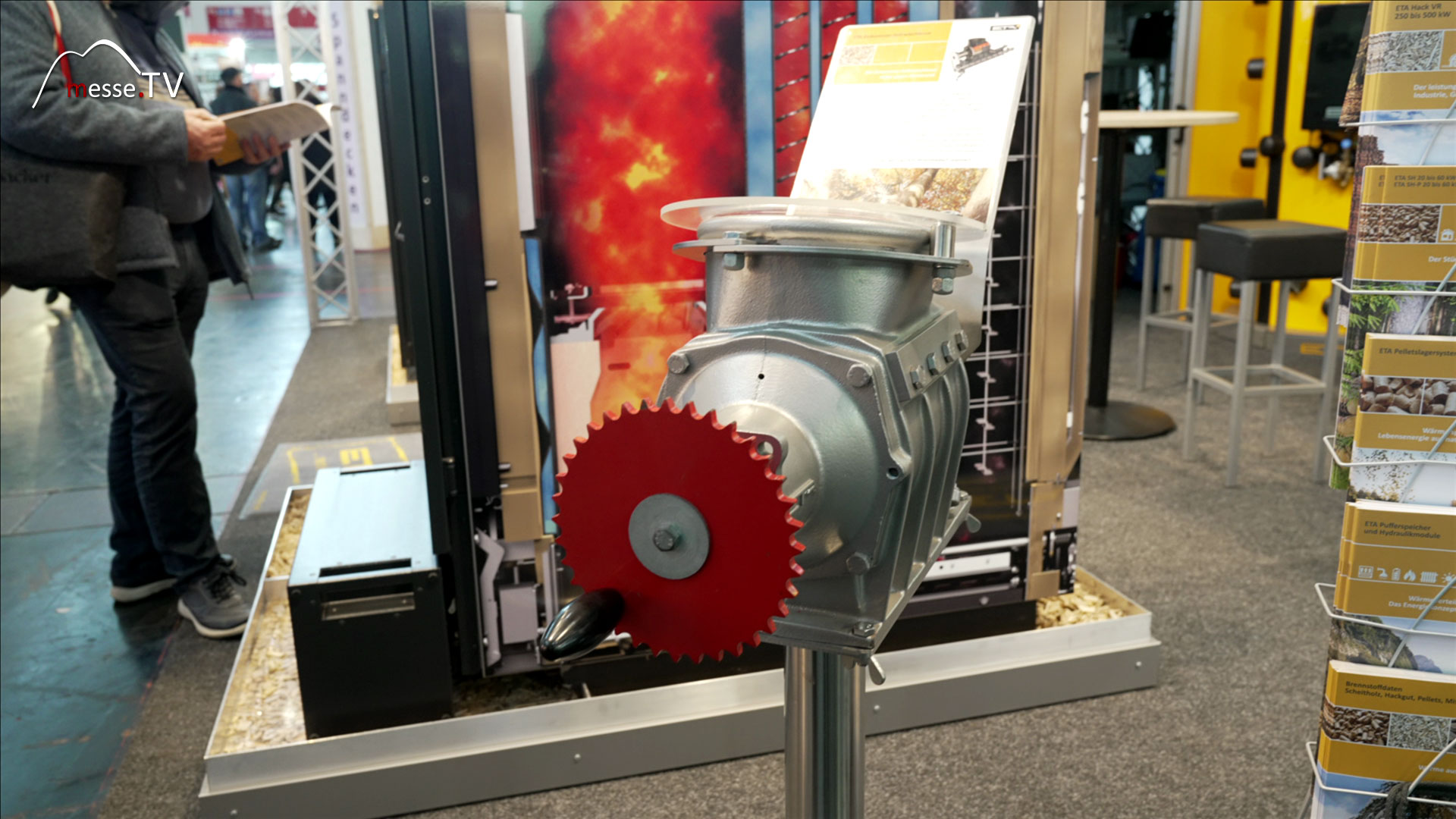

At the trade fair Heim und Handwerk, it will be demonstrated how the pellet condensing boiler works with a suction system. The pellets are fed once a day from the store into an integrated daily container. From there, the boiler is automatically fed, which transfers the heat generated to the central heating system. This solution ensures consistent operation and significantly reduces the manual effort required on a daily basis. Fuel is replenished as required without the operator having to constantly intervene.

Another key issue is ease of operation. Behind the panel door of the condensing boiler is a clearly structured graphical control unit. All important settings can be easily made and controlled via the display, without in-depth technical knowledge. At Heim+Handwerk, it is clear that the control system is designed for clarity and comprehensibility. Operating states, temperatures and relevant parameters are clearly displayed and enable quick orientation.

The target group for pellet condensing boilers ranges from private homeowners to commercial and industrial users. Careful planning is required, especially when converting existing heating systems. Space requirements, pellet storage and integration into the existing heating system must be checked in advance. It is therefore advisable to make an appointment with a specialist installer on site to select the right system. In this way, it can be clarified whether and how the condensing boiler can be optimally integrated into the existing system.