The requirements for lift control systems have changed significantly in recent years. Rising costs, increasing technical complexity and a growing need for flexibility characterise the everyday work of many lift companies. At the same time, the job profile of fitters is changing.

Digital interfaces, networked systems and software-based functions are increasingly becoming the norm. Against this backdrop, the control system is becoming more of a focus as a central element of the system. Rocket Aufzugtechnik has deliberately specialised in precisely this core component. Instead of building up a broad product portfolio, the company focuses on developing an elevator control system that combines as many requirements as possible in a single system. The current generation is the result of intensive feedback from practical experience and has been specifically designed for expandability, flexibility and cost-effectiveness.

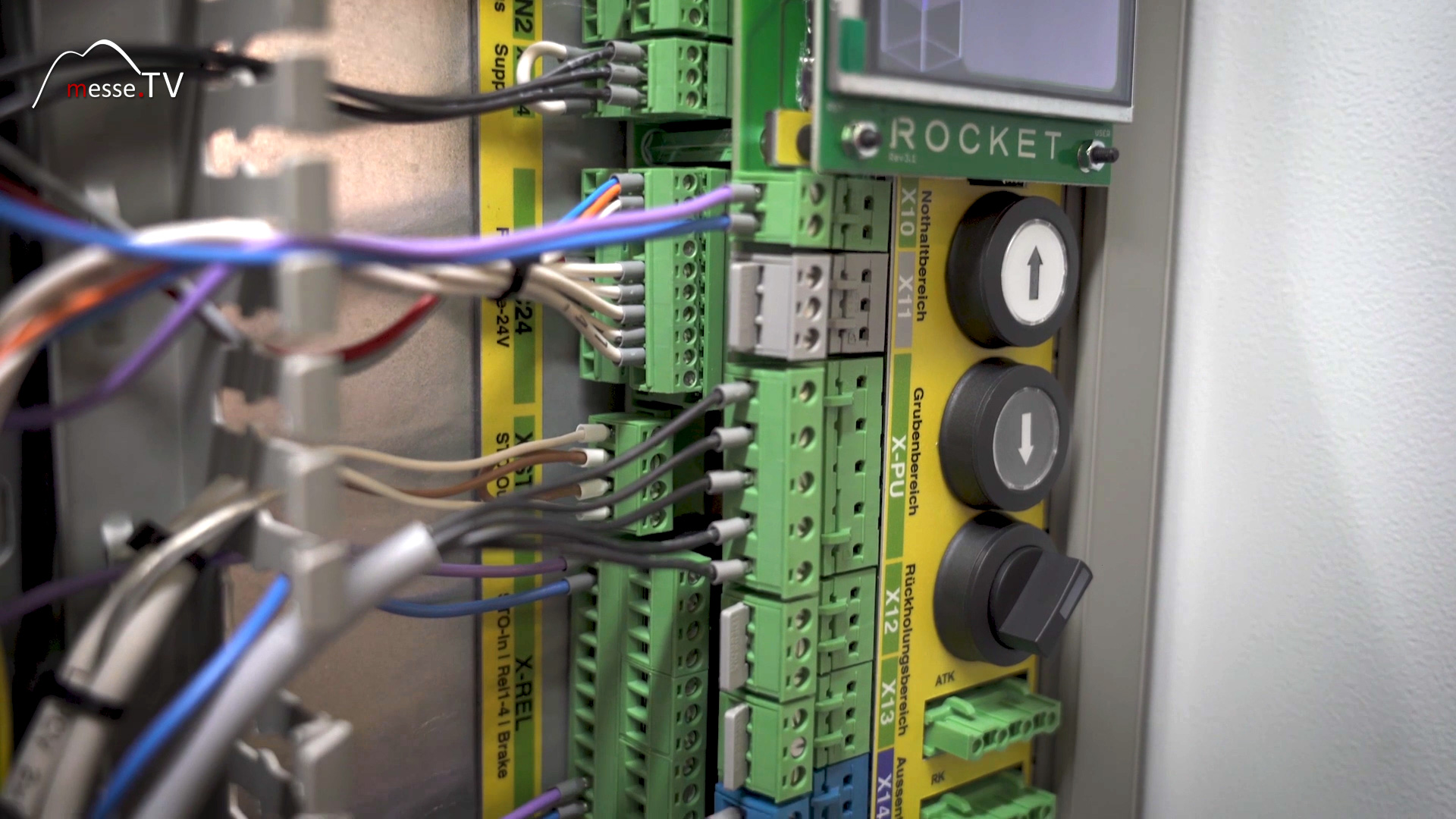

The starting point for the new generation of control systems was the increasing price pressure in the market. Material costs, energy prices and the cost of installation and maintenance have risen significantly. The aim of the development was therefore to reduce installation costs without compromising on functionality. A key concept is minimal basic wiring. The fewer basic components that need to be installed, the faster and more cost-efficiently a system can be put into operation. At the same time, care was taken to make the control system as open as possible. It can control different frequency converters and is compatible with various hydraulic units. No additional circuit boards or external modules are required for this. This level of integration clearly distinguishes the system from classic control concepts, which often consist of many individual assemblies.

A key feature of the new generation is its high degree of integration. Functions that are implemented in other systems via additional hardware are directly mapped in the control system here. This not only simplifies installation, but also reduces potential sources of error. Fewer interfaces mean fewer dependencies and clearer system logic. The control system is completely touch-based and internet-enabled. Settings, adjustments and diagnostics can be made directly via the interface. This brings the control system closer to operating concepts familiar from everyday use of digital devices. Operation is based less on technical codes and more on clear menus and visual structures.

A conscious design approach was to base the system on the smartphone principle. The control system has a modular structure and can be expanded with additional applications. Apps are available for special functions and can be integrated as required. This principle corresponds to the approach that many fitters are familiar with from their private lives. Younger maintenance and service technicians in particular are more familiar with digital interfaces than with classic analogue operating concepts. The training period is shortened because the logic of the control system is intuitive. Adjustments can be made more quickly and errors are easier to locate. The control system feels less like a specialised industrial product and more like a familiar digital tool.

Another requirement was broad applicability. The control system is not limited to a specific type of system. It can be used in both cable lifts and hydraulic systems. Different configurations can be mapped on the software side without having to adapt the hardware. This flexibility is particularly relevant for small and medium-sized lift companies. They often manage a heterogeneous plant portfolio and have to make do with as few systems as possible. A uniform control system simplifies storage, training and maintenance. Typical features of the new control system include:

The presentation at interlift was a deliberate choice. The trade fair is considered a central meeting place for the industry and offers the opportunity to talk directly with users. Feedback from these discussions is immediately incorporated into further development. The control system is not intended to be a finished product, but rather a platform that can be adapted to new requirements. Rocket Aufzugtechnik is thus positioning itself as a supplier that closely links technical development with practical application. The focus is less on maximum functional diversity and more on a clear, integrated solution that proves its worth in everyday use. The control system is intended to be a tool that reduces the workload for both fitters and operators.

The increasing cost pressure in lift construction cannot be offset by cheaper components alone. Efficiency is achieved primarily through simplification. Less wiring, fewer additional modules and intuitive operation contribute to more economical project implementation. Digital lift control thus becomes a lever for combining technical requirements and economic constraints. The new generation shows that control technology today can be more than just a switching element. It becomes the digital control centre of the system, bringing together technology, operation and networking. For modern systems, it is precisely this combination that is crucial.