Safety components are among the invisible but key components in lift construction. They work in the background, are barely noticeable during normal operation and only become relevant when they need to function reliably.

Interlift demonstrates how technically differentiated this segment is and how high the requirements for quality, compliance with standards and adaptability have become. Especially when it comes to safety-related components, it is not innovation for its own sake that determines market acceptance, but rather robust technology. Jungblut has been active in the field of safety components for lifts and conveyor technology for almost a century. This long market presence shapes the standards for its own products as well as its customer relations. At the trade fair, a wide range of speed limiters will be presented, covering different applications and installation situations. The large number of exhibits is not an end in itself, but rather an expression of a technical range that responds to real requirements in lift construction.

In a safety-relevant environment, experience is not an abstract value, but part of technical reliability. Jungblut does not see itself as a newcomer, but as an established manufacturer that has been developing its products for decades. Production is based on high quality standards, which are reflected in both the choice of materials and the mechanical design. This focus is particularly evident in the speed limiters, which are designed for different speed ranges. From home lifts with very low travel speeds to classic passenger lifts with significantly higher speeds, the current market is largely covered. The portfolio is therefore not aimed at niche applications, but at everyday lift construction.

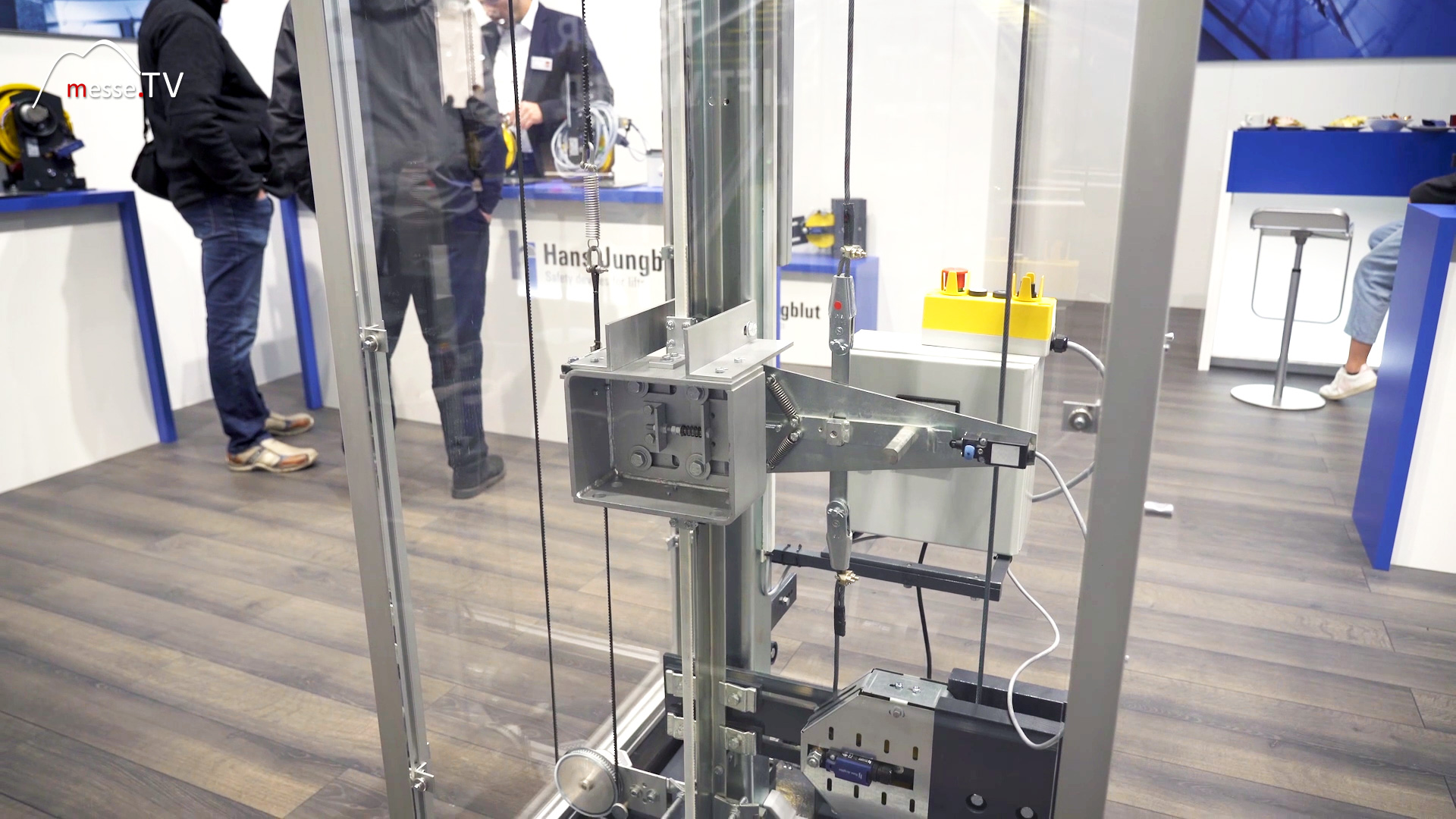

A key feature of the products presented is their coverage of typical speed ranges. Applications start at very low travel speeds, for example in private or semi-public areas. At the upper end of the spectrum are systems with travel speeds of several metres per second, as is common in classic passenger transport. The majority of demand is for standard models, which are installed in many lifts. These models form the backbone of the range and are designed for availability, ease of maintenance and compliance with standards. This standard range is supplemented by smaller and larger variants to accommodate different structural requirements.

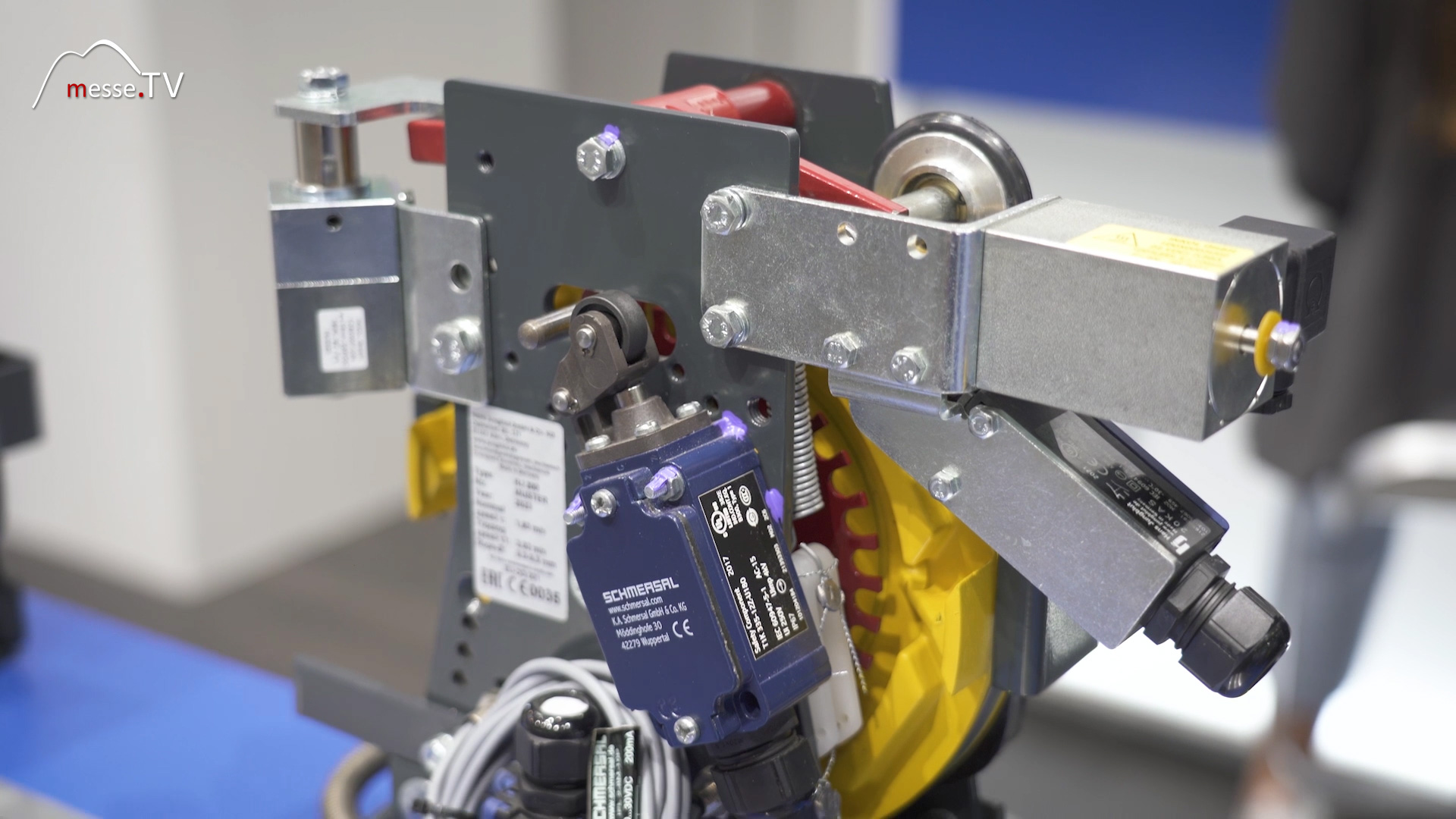

The trade fair will showcase not only the speed limiter as a component in itself, but also its possible extensions. One exhibit has been deliberately equipped with various add-ons to illustrate the technical options to customers. This modularity makes it possible to adapt the basic product to specific requirements without having to completely redesign it. One example is the remote release, which is used for catch tests. It allows the catch mechanism to be triggered in a targeted manner, for example during tests or inspections. The intervention is controlled by a mechanical element that puts the limiter into the catch state. Such solutions are particularly relevant for recurring tests and help to simplify processes. Typical equipment and customisation options include:

In addition to series production, the ability to customise plays an important role. Not every system complies with the standard, and not every installation situation can be solved with a catalogue product. Jungblut therefore attaches great importance to developing special solutions together with its customers. This may involve special attachments or design modifications to existing systems. This openness to individual requirements is particularly important in the safety-relevant environment. It allows even complex or atypical systems to be equipped in accordance with standards without compromising safety. At the same time, the link to series production is maintained, which has a positive effect on quality and cost-effectiveness.

Speed limiters are not isolated components, but part of a complex safety system in the lift. Their design influences the interaction with safety gear, controls and mechanical components. The requirements for precision and reliability are correspondingly high. The presentation at Interlift makes it clear that innovation in this area is defined less by visible innovations and more by attention to detail, compliance with standards and adaptability. Jungblut positions itself here as a manufacturer that relies on proven technology, but continuously develops it further. In a market where safety is the top priority, it is precisely this balance that remains crucial.