In many buildings, lifts have been operating reliably for decades, but at the same time they are becoming outdated in terms of technology and energy efficiency. Hydraulic systems in particular are considered durable, but their control, regulation and energy efficiency often no longer meet current standards.

The modernisation of such existing lifts is therefore less a matter of replacement due to wear and tear than a targeted further development of existing technology. The focus is on interventions that have as little impact as possible on ongoing operations while still enabling noticeable improvements. Particular attention is paid to the drive system, as it has a significant impact on the interplay between ride comfort, energy consumption and maintenance requirements. The challenge is to integrate new components in such a way that they remain compatible with the existing infrastructure while at the same time opening up digital functions that were not previously available.

Hydraulic lifts have proven themselves particularly in goods lifts and in buildings with special requirements. Their robustness allows central components to remain in the shaft for very long periods of time. It is precisely this fact that makes lift modernisation attractive: instead of replacing entire systems, the drive and control system can be renewed while load-bearing components continue to be used. Modern, frequency-controlled drives offer clear advantages. They enable finer control of movement, reduce start-up and braking losses and significantly lower energy consumption. At the same time, they contribute to smoother running. Sustainability and energy savings are not abstract concepts here, but a direct result of a modern drive system design.

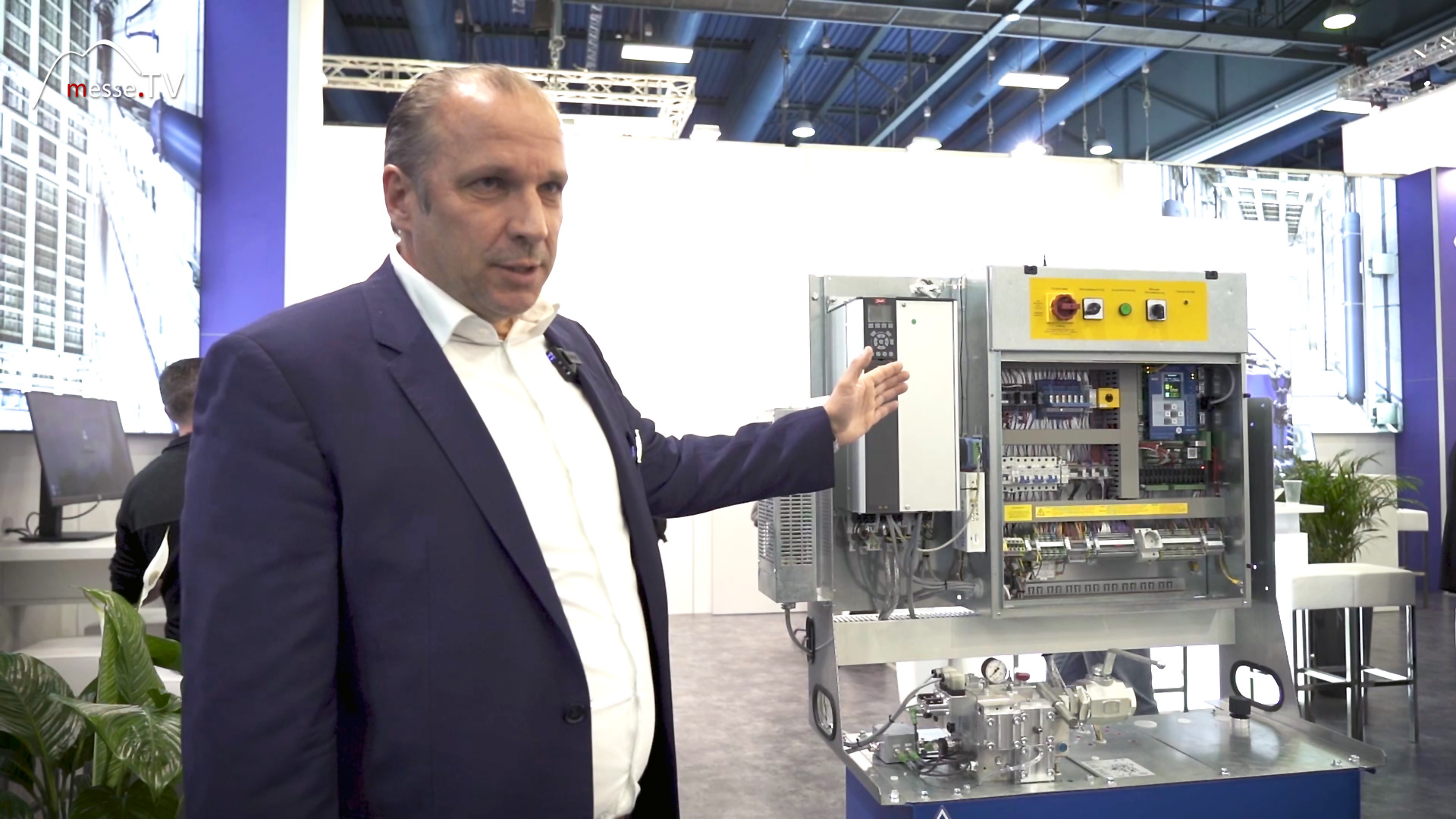

A key advance in modern lift technology lies in the networked interaction between the control system and the drive. This connection allows operating data to be read out and parameters to be adjusted without being physically present at the system. Such a networked concept enables remote access to system values and extends classic maintenance processes with digital functions. This creates significant added value for operators and service companies. Downtimes can be analysed more quickly, and adjustments can be made in a targeted manner without unnecessary on-site visits. The networked drive system thus becomes an active part of system operation and not just a mechanical component.

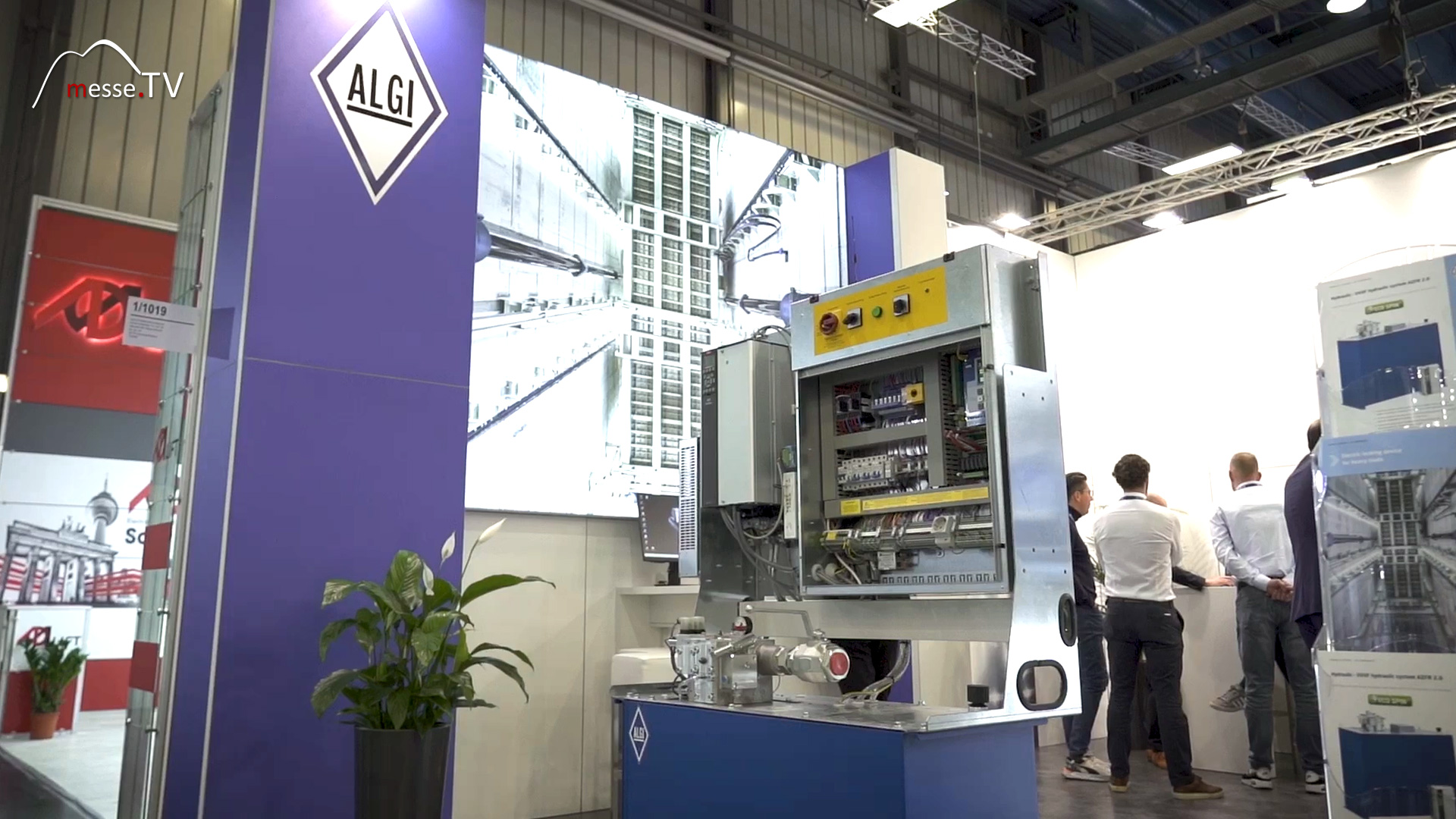

In addition to technical performance, feasibility plays a central role. In sensitive environments such as hospitals or hotels, an elevator must be quickly available again after modernisation. Concepts based on pre-assembled modules significantly reduce installation time. The unit, control system and frequency converter are prepared in such a way that only a few plug connections need to be made on site. Fastening is carried out via clearly defined points. This approach minimises downtime and at the same time reduces the risk of assembly errors.

Another aspect of modern lift solutions is the bundling of technical components into a coordinated overall system. Operators prefer solutions in which the drive, control and regulation are not considered in isolation, but are designed as a functional unit.

The further development of existing systems is more than just a technical measure. It is a strategic decision for economic efficiency, operational safety and sustainability. Hydraulic lifts in particular demonstrate how the targeted renewal of individual components can generate long-term benefits. As a long-established family business, Algi adopted this approach early on and translated it into practical solutions. The combination of proven hydraulics and networked control technology is exemplary for an industry that is advancing technologically without abandoning its fundamentals. Algi is thus clearly positioning itself in the field of modern lift modernisation with networked drive systems.