In lift construction, motion is not an abstract process, but a safety-critical condition. Position, speed and deceleration must be precisely recorded at all times in order to minimise risks for users, maintenance personnel and equipment.

With the increasing technical complexity of modern lifts, the importance of sensor technology that not only measures movements but also reliably translates them into control-relevant information is also growing. Safety is no longer achieved solely through mechanical redundancy, but through the quality of the data recorded and its evaluation. Fritz Kübler GmbH has been developing systems for recording, measuring and transmitting motion information for many years. As a second-generation family-run company, the manufacturer operates internationally and has several production and development sites. Its specialisation in motion sensor technology forms the basis for applications in various industries, but is particularly relevant in lift construction, where technical precision is directly linked to personal safety.

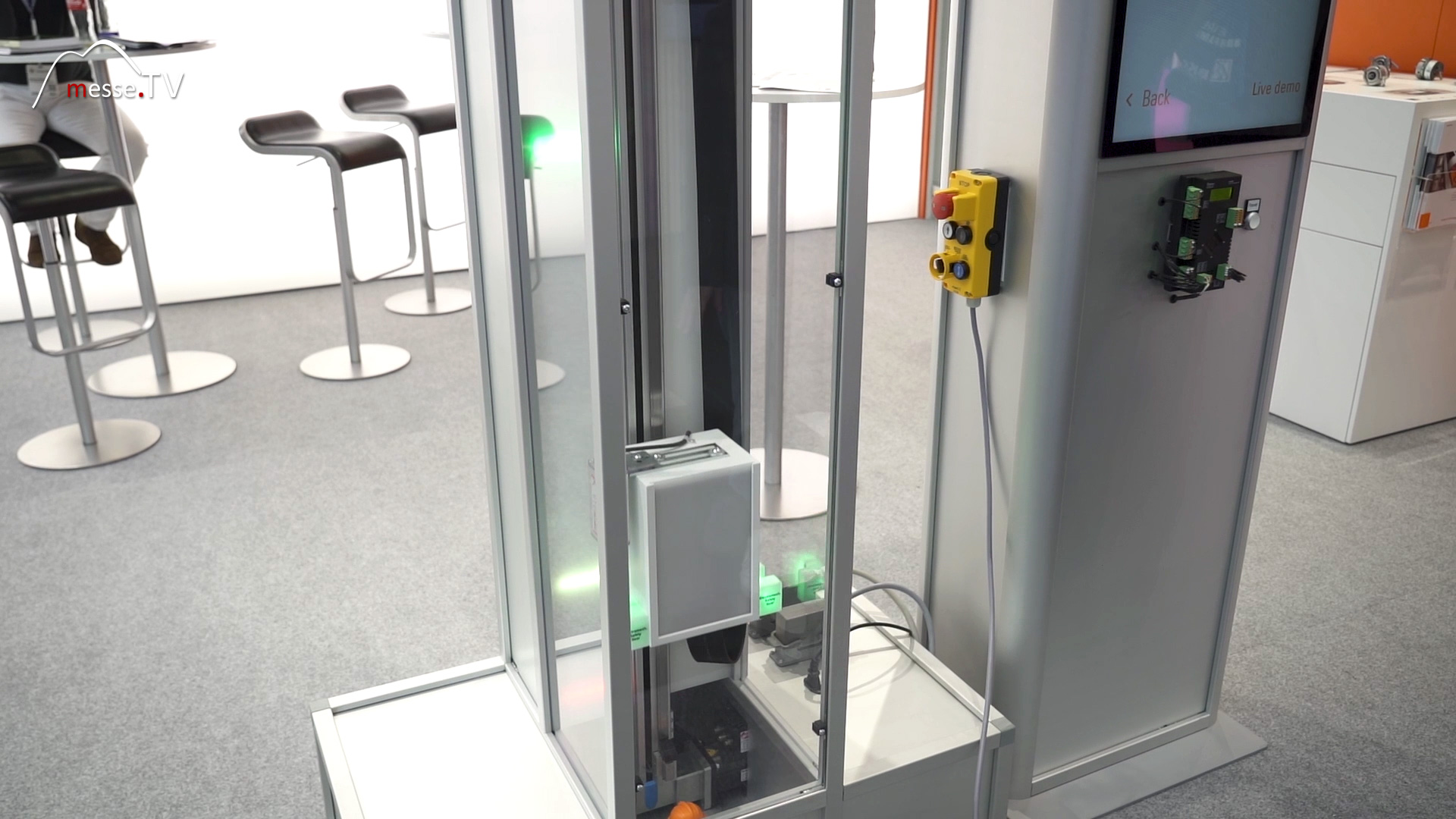

In classic lift construction, safety-related functions are often covered by several separate components. Limit switches, speed limiters and other mechanical devices each perform clearly defined tasks. Modern sensor technology makes it possible to combine these functions and evaluate them digitally on the basis of continuously recorded motion data. A key example is a shaft copying system consisting of a sensor for recording speed and position and an evaluation unit. The sensor data is continuously processed and forwarded to the control system. This allows safety-related functions to be triggered directly without the need for additional mechanical components. Movement thus becomes the central source of information for safe operation.

The digital processing of motion information allows several safety functions to be mapped with software support. These include end position monitoring, control of unwanted car movements and functions for detecting overspeed. In certain system configurations, it is even possible to dispense with a separate mechanical speed limiter, as its task is taken over by sensors and evaluation. This approach reduces the number of individual components and simplifies the system architecture. At the same time, the requirements for sensor reliability and functional safety of the evaluation increase. Safety is not achieved here through mechanical diversity, but through precise data acquisition, stable algorithms and comprehensible system logic.

A particularly sensitive stage in the life cycle of a lift is the assembly phase. During this time, the drive and control system are often not yet active, but movements are still taking place in the shaft. Especially in the case of scaffold-free assembly, there is an increased risk for the assembly personnel. Sensor-based systems can also perform protective functions in this early phase. Continuous position detection allows movements to be limited to a very narrow range. Platforms can only move minimally, preventing uncontrolled movements. Safety is thus ensured not only during regular operation, but also during installation of the system.

During operation, sensor-based systems enable comprehensive monitoring of safety-relevant conditions. Excessive speed, unwanted cabin movements or unusual delays can be reliably detected. Additional control functions ensure that deviations are identified at an early stage and appropriate measures are taken. Typical safety-related functions include:

In addition to immediate safety, the energy consumption of lifts is also becoming a greater focus. Sensors and digital evaluation make it possible to put systems into energy-saving modes in a targeted manner. In buildings with clearly defined usage times, the power supply can be switched off outside of operating hours. During these phases, the lift remains in a safe position, the brakes are applied in a controlled manner and no energy is consumed. This results in noticeable savings overnight or at weekends without compromising the safety or availability of the system. The lift thus becomes part of a more efficient and sustainably operated building.

The use of modern motion sensor technology shows that safety in lift construction is increasingly being organised on a data-based basis. Movements not only provide snapshots, but also form the basis for decisions on operation, maintenance and energy use. Instead of looking at individual functions in isolation, motion data is evaluated holistically. In this environment, Fritz Kübler positions itself as a supplier that understands motion sensor technology as an integral part of modern lift technology. The combination of precise data acquisition, digital evaluation and safety-oriented functions illustrates how existing lift systems can be further developed technically without calling their basic architecture into question.