Hydraulic lifts still dominate the building stock of many cities today. They are considered durable, maintenance-friendly and robust, but are coming under increasing pressure as energy efficiency and sustainability become more important. Operators are faced with the question of how existing systems can continue to be used without completely replacing them or overloading them technically.

Hydroware develops control and drive solutions that address precisely this issue. The focus is on the technical advancement of existing lifts. The aim is to modernise them in a way that recovers energy, standardises systems and takes into account both hydraulic and rope-driven lifts without fundamentally changing the character of the systems. The company was founded in 1998 with a clear focus on hydraulic drives and control systems for lifts. Since then, Hydroware has maintained a continuous presence on the market. The company entered the German market in 2013, and since then its solutions have also been used and further developed here. This long-standing specialisation forms the basis for the current move towards modernisation and sustainability.

Starting with classic hydraulics, the company is expanding its portfolio to include modernisation solutions for cable lifts. Instead of installing new systems, the existing technology is upgraded with a new control system. The approach follows the concept of the circular economy: functioning lifts are retained, but are adapted to current requirements in terms of energy and technology. The new control system is designed to support different drive systems. This eliminates the need for separate control systems for hydraulic and cable-driven lifts. Modernisation thus becomes a targeted intervention rather than a comprehensive replacement.

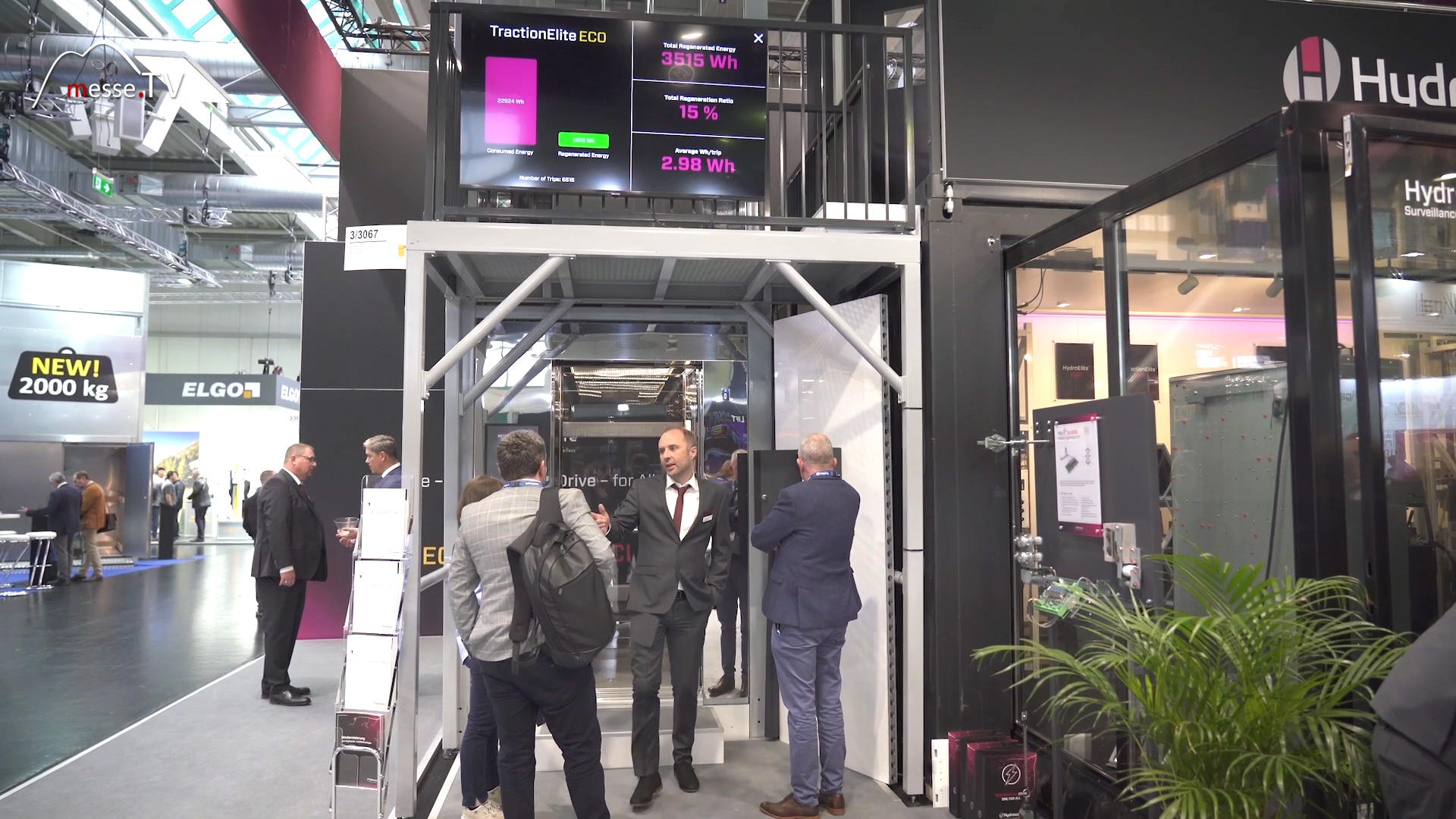

A central element of the development is energy recovery. While conventional lifts draw energy exclusively from the mains, the new system enables the return of regenerative energy. The display shows how much energy is consumed and how much is fed back into the grid. The display clearly distinguishes between consumed energy and recovered power. In addition, the ratio of both values, the so-called regeneration ratio, is shown. Energy efficiency is thus not only implemented technically, but also made transparently traceable.

Under the guiding principle of ‘One for All’, Hydroware pursues the goal of providing a control system for different drive systems. Both rope lifts and hydraulic systems can be operated with the same control architecture. This concept is complemented by a frequency converter developed in-house, which is specially designed for energy recovery. This standardisation simplifies planning, installation and maintenance. For operators, it means less complexity, and for service teams, consistent system logic across different lift types.

A common problem with hydraulic lifts is that the system heats up during operation. The new drive solution offers clear advantages here. Thanks to the modern frequency converter, the oil temperature remains largely constant even during intensive use. The drives heat up significantly less than with conventional solutions. At the same time, it is possible to see how many trips have been made and how energy consumption and energy recovery relate to each other. In practice, a significant proportion of the energy consumed can be fed back into the grid. This not only improves efficiency but also protects mechanical components.

Sustainability is not achieved by completely replacing lifts, but through targeted technical interventions. The focus is on extending the service life of existing systems and reducing energy consumption. This approach follows the principle of the circular economy and avoids unnecessary consumption of materials and resources. Typical effects of modernisation include:

The solution presented shows that hydraulic lifts can also meet today's regulatory and energy requirements. Modern control systems, renewable energy and cross-system concepts help to ensure that existing systems do not become a renovation problem, but remain part of sustainable building technology. Hydroware is thus positioning itself as a supplier that understands technical innovation as further development. The combination of control systems, renewable energy and targeted modernisation makes it clear that lifts can meet today's requirements even with proven technology.