Hydraulic lifts play a central role wherever heavy loads need to be moved safely, in a controlled and reliable manner. In industrial plants, workshops or logistics buildings, stability, precision and operational safety are more important than speed or design. It is precisely in this environment that ALGI positions itself as a long-established manufacturer of hydraulic lift components with decades of experience.

For more than seven decades, the company has been developing and manufacturing solutions for demanding application scenarios. The focus is not on individual components, but increasingly on fully integrated systems that are geared to the real requirements of heavy loads.

Hydraulic drives are considered particularly robust, low-maintenance and load-stable in lift construction. Especially with high payloads, they offer design advantages over other drive concepts. Cylinders, power units and the associated control system are designed to move large masses evenly and position them precisely. In practice, this means that the cabin remains controllable even at maximum load, load changes have less of an abrupt effect, and the entire system operates more smoothly. This feature is crucial for industrial applications, as goods that are unevenly distributed or very heavy are often transported here.

A key issue with heavy-duty lifts is the so-called deflection of the cabin. If a lift cabin is loaded with heavy loads while stationary, it can lower slightly due to hydraulic forces. This deflection may be explainable from a design perspective, but in practice it poses a safety and comfort problem. An absolutely stable cabin position is essential, especially when loading and unloading heavy goods. Even slight changes in height can disrupt the flow of materials or lead to dangerous situations. There is therefore a high demand for technical solutions that reliably prevent this deflection.

ALGI responds to this need with an electric lock in the form of a locking bolt. This component supplements the hydraulic lift with a mechanical-electrical safety device that is specially designed to keep the cabin stationary. Shortly before reaching the stop, a bolt extends, onto which the lock is hydraulically applied. In this state, the cabin is mechanically fixed. It remains stable during subsequent loading, preventing any springing. Only when the journey is resumed does the cabin lift slightly, the bolt retracts and normal lift operation begins. The function is technically unspectacular, but its effect is decisive. It ensures a significantly higher level of safety and precision in daily operation.

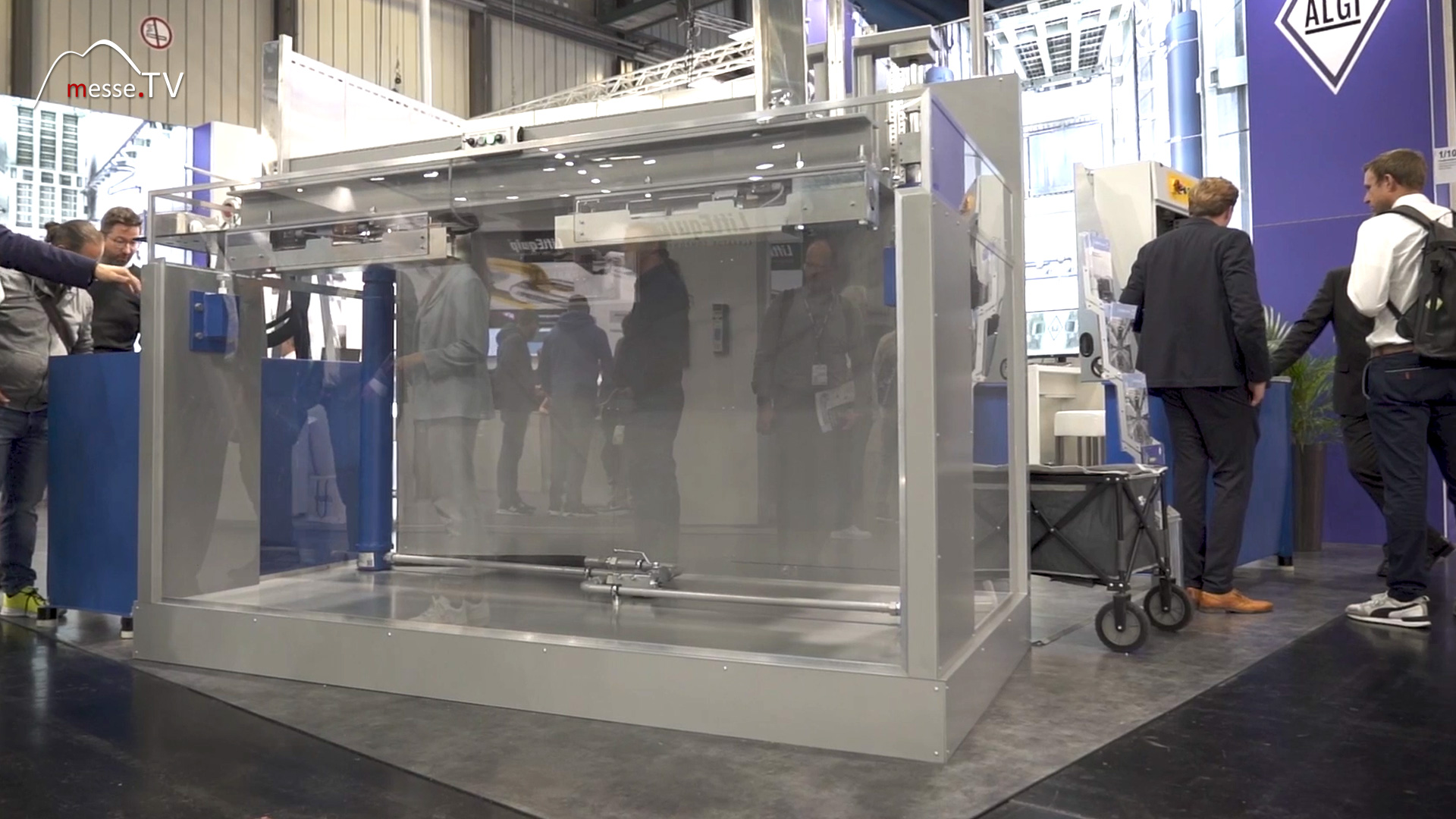

A key aspect of current developments is the desire of many customers for integrated solutions. Instead of purchasing the drive, steel construction, cabin and additional components from different suppliers, there is growing demand for systems from a single source. This is exactly where ALGI comes in. In addition to cylinders and power units, the portfolio also includes complete steel construction and specially designed cabins for heavy-duty applications. The electric locking system is not an add-on, but a logical component of the overall system. Typical components of such a complete package are:

In many industrial projects, electric locks are now an explicit part of tenders. The reason is obvious: safety requirements are increasing, standards are becoming more precise, and operators expect solutions that not only work but also actively minimise risks. Electrical locking to prevent deflection is therefore no longer an optional detail, but increasingly a required standard. It adds an additional level of safety to hydraulic technology without unnecessarily complicating operation.

It is striking that the solution presented is not a revolutionary individual innovation. Rather, it is a consistent further development of existing technology. The hydraulic drive, steel construction, cabin and locking mechanism interact to form a closed system. It is precisely this system logic that characterises ALGI's current approach. The hydraulic lift is no longer understood as the sum of individual components, but as a technically coordinated overall package that meets the real demands of industrial applications. This clearly positions the company in a segment where reliability, safety and technical clarity are more important than spectacular innovations. For operators of heavy-duty lifts, this is precisely a decisive criterion.