The development of modern lift systems is no longer determined solely by load capacity and speed. Efficiency, use of materials and global applicability have become key criteria. International markets in particular demonstrate how different technical standards, construction methods and regulatory frameworks can be.

For manufacturers of drive and lift components, this means developing solutions that are both technologically sophisticated and flexible in their application. A German family business whose roots date back to the early twentieth century is a prime example of this approach. Since its foundation in 1910, the company has remained in family hands and has developed over decades from a national supplier to a globally active industrial enterprise. The active role of the founding family continues to shape the strategic orientation and long-term thinking of the company to this day.

International expansion took place gradually, driven by technical specialisation and stable customer relationships. Today, the company is present in more than a hundred countries and has locations and partnerships on almost every continent. This growth is not a short-term effect, but the result of continuous investment in development, manufacturing and market proximity. In recent years in particular, global demand for energy-efficient and space-saving lift solutions has increased significantly. Densely populated cities, rising construction costs and stricter sustainability requirements are leading to classic concepts being increasingly questioned. This is precisely where new drive technologies come in, enabling more compact designs while reducing energy consumption.

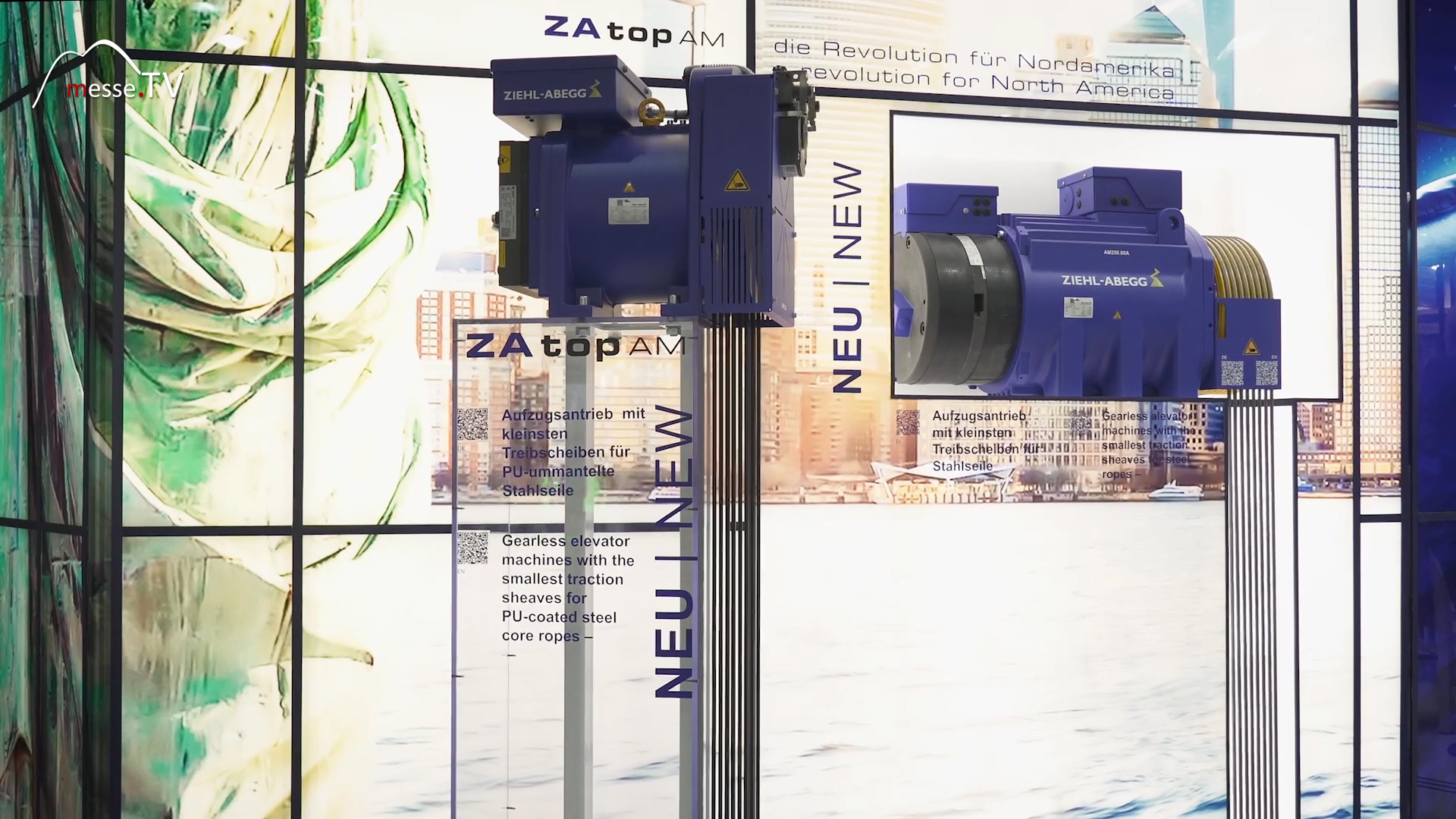

The North American region is a clear example of this market diversity. While certain technologies have been established in Europe for years, they are still considered novel in some parts of the USA and Canada. This applies in particular to the use of plastic-sheathed ropes in lifts. These rope systems have proven themselves in Europe for more than a decade, but they represent a real innovation in the North American market. At international trade fairs, products that are specifically tailored to these regional characteristics are therefore presented. Presentation areas that represent individual regions of the world illustrate how solutions can be adapted to local conditions without sacrificing a common technological basis.

At the heart of current developments is the combination of drive and plastic-sheathed rope technology. These ropes differ fundamentally from classic steel ropes. They have a plastic sheath that protects the inner steel strands and at the same time enables other mechanical properties. This results in decisive advantages for drive construction. The most important effect is the possibility of using significantly smaller drive sheaves. Smaller drive sheaves require less torque, which in turn allows for more compact motors. This makes it possible to develop machines that are significantly smaller, lighter and more efficient than conventional systems with the same payload. This connection is technically clear, but its implications for lift construction are far-reaching.

The reduction in the size of drives opens up new degrees of freedom for lift manufacturers. Machine rooms can be smaller or eliminated altogether, shafts can be planned more efficiently and the overall use of materials is reduced. This aspect is particularly relevant in urban building projects, where every square metre counts. In addition, the lower weight of the drive components has a positive effect on the overall design. Lighter machines reduce the static requirements on buildings, which in turn allows the use of slimmer supporting structures. This results in an overall system that is not only more technically efficient but also more economically attractive.

The effects described above benefit not only lift manufacturers, but also subsequent operators. More efficient drives require less energy, which reduces operating costs. At the same time, the lower material consumption reduces the ecological footprint already in the manufacturing phase. The typical advantages of this technology can be summarised as follows:

In this context, sustainability is not understood as an isolated feature, but as the result of technical optimisation. When materials are saved, machines are made smaller and energy consumption is reduced, this automatically has a positive effect on the environment and resources. This approach is particularly valuable for international markets with different regulatory requirements, as it is universally applicable. Ziehl-Abegg positions itself in this environment as a supplier that combines technological innovation with long-term responsibility. The combination of a family-run structure, global presence and consistent further development forms the basis for solutions that meet both current and future requirements. This shows what technical progress in lift construction can look like when it is consistently thought out from a system perspective.