Lift construction is traditionally characterised by individual solutions. Special designs are particularly in demand where structural conditions do not allow for classic standard shafts. At the same time, there is a growing need for standardised systems that can be planned more quickly, installed efficiently and operated economically. This tension has given rise to concepts that combine technical individuality with a modular structure.

A family-run business from Frankfurt am Main has been working in lift construction for more than five decades and usually specialises in special systems. Currently, however, it is deliberately presenting standardised systems that have nevertheless been developed based on the logic of individual solutions. The focus is on compact glass lifts with aluminium frames that can be flexibly integrated into different environments.

The system concept presented is based on three models that differ in their square footprint. The designations follow a clear logic. The abbreviation Q stands for the square design, and the number that follows describes the respective external dimensions. This results in variants with different basic dimensions that can be adapted to common installation situations. This system facilitates planning and selection. Architects, builders and operators can quickly identify which model is suitable for the respective situation. Despite standardisation, there is still sufficient scope for customisation, for example in terms of access, design or area of application.

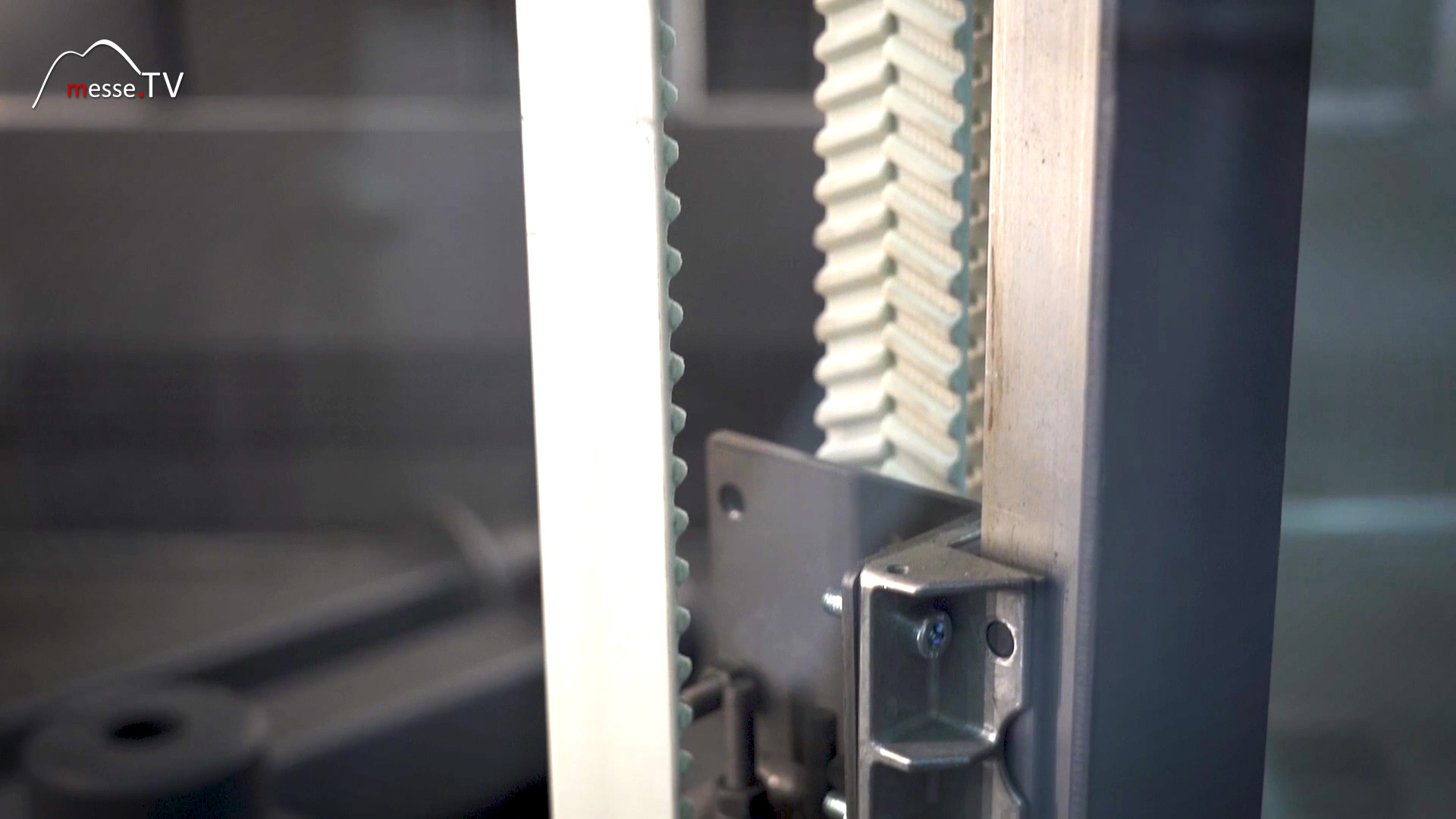

One of the technical features of the system is the belt drive used. Instead of classic cables, a modern plastic belt reinforced with steel cables is used. This combination combines flexibility and stability. The belt runs visibly along the structure, making the technology easy to understand. The entire drive technology is compactly integrated into one corner of the system. This saves valuable space and creates a clearly structured design. Concentrating the technology in one place also has an impact on maintenance and accessibility. Service work can be carried out in a targeted manner without having to open up the entire system.

The corner integration of the technology offers a further advantage. Theoretically, access is possible from all four sides, but in practice a maximum of two access points are realised. This flexibility is particularly relevant in confined or architecturally challenging situations. Depending on the installation location, it is possible to decide where doors should be placed. For operators, this means more freedom in designing the environment. The lift can be better integrated into existing structures without the need for extensive modifications. The system adapts to the building, not the other way around.

A particularly striking feature is the shallow depth of the shaft pit. At around forty centimetres, it is significantly less than what is usual in classic lift construction. This is made possible by the highly integrated technology and compact design of the drive. This feature opens up new application possibilities. In existing buildings, during retrofitting or in sensitive structural situations, interventions in the building fabric can be minimised. Especially where deep foundation work is not possible or economically viable, a shallow shaft pit can make all the difference.

The shaft frame is made of aluminium and is designed as a glass frame. Aluminium offers several advantages. It is light, stable and corrosion-resistant. Rust is not an issue with this material, which makes it easy to use outdoors. At the same time, the glass frame allows for an open, transparent design. The combination of aluminium and glass gives the system a clear, technical character. It blends in with both modern interiors and outdoor areas, such as extensions or separate access points. The lift is visible without being dominant. Typical features of the system include:

The systems presented show how experience gained from custom system construction can be transferred to standardised products. Instead of designing individual solutions from scratch each time, proven principles are systematised. The result is lifts that are plannable, reproducible and yet flexible in their application. Thoma Lifts brings decades of experience from individual projects to this concept. Standardisation does not mean a loss of quality, but rather a focus on essential technical features. The design, drive and shaft are coordinated in such a way that they work in many situations without requiring complex special solutions.

Thanks to their corrosion-free frame and compact design, the systems are not only suitable for classic interiors. There are also applications in outdoor areas, such as for subsequent developments or barrier-free access. The technology remains protected and the construction durable. The concept thus responds to a market that increasingly demands flexible solutions. Buildings are being repurposed, expanded or adapted. Lifts must be able to keep pace with this change. This is precisely where the strength of such systems lies. With these systems, Thoma Lifts demonstrates how technical reduction, clear design and structural flexibility can be combined. The step from purely specialised systems to structured models is not a break, but a further development based on practical experience.