When it comes to tunnelling technology and tunnel boring machines, there is no getting around Herrenknecht. We visit the global market leader at bauma 2016 to gain an insight into its work, challenges and solutions. If you want to aim high in this business field, you have to be able to drill far down.

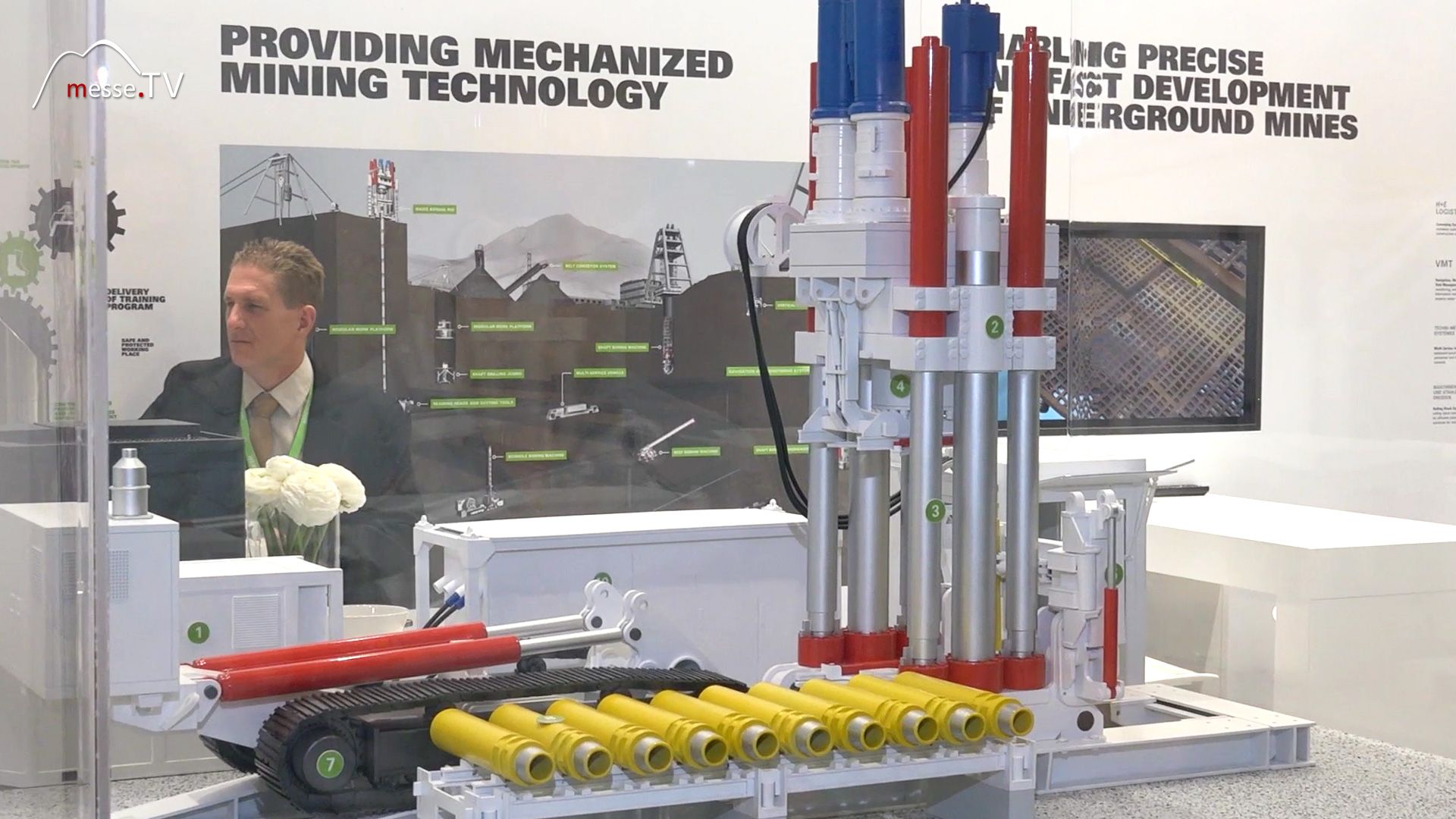

Felix Rother: Mr. Hotz, Herrenknecht is obviously a company that has something to do with underground mining. Could you explain to me what Herrenknecht stands for? Stefan Hotz: The Herrenknecht brand stands for customer-oriented solutions in the mechanized mining sector. We implement things that we got from our big parent company, i.e. we are active in the tunneling business. And we have now translated these solutions and applications into "applications for mining and underground".

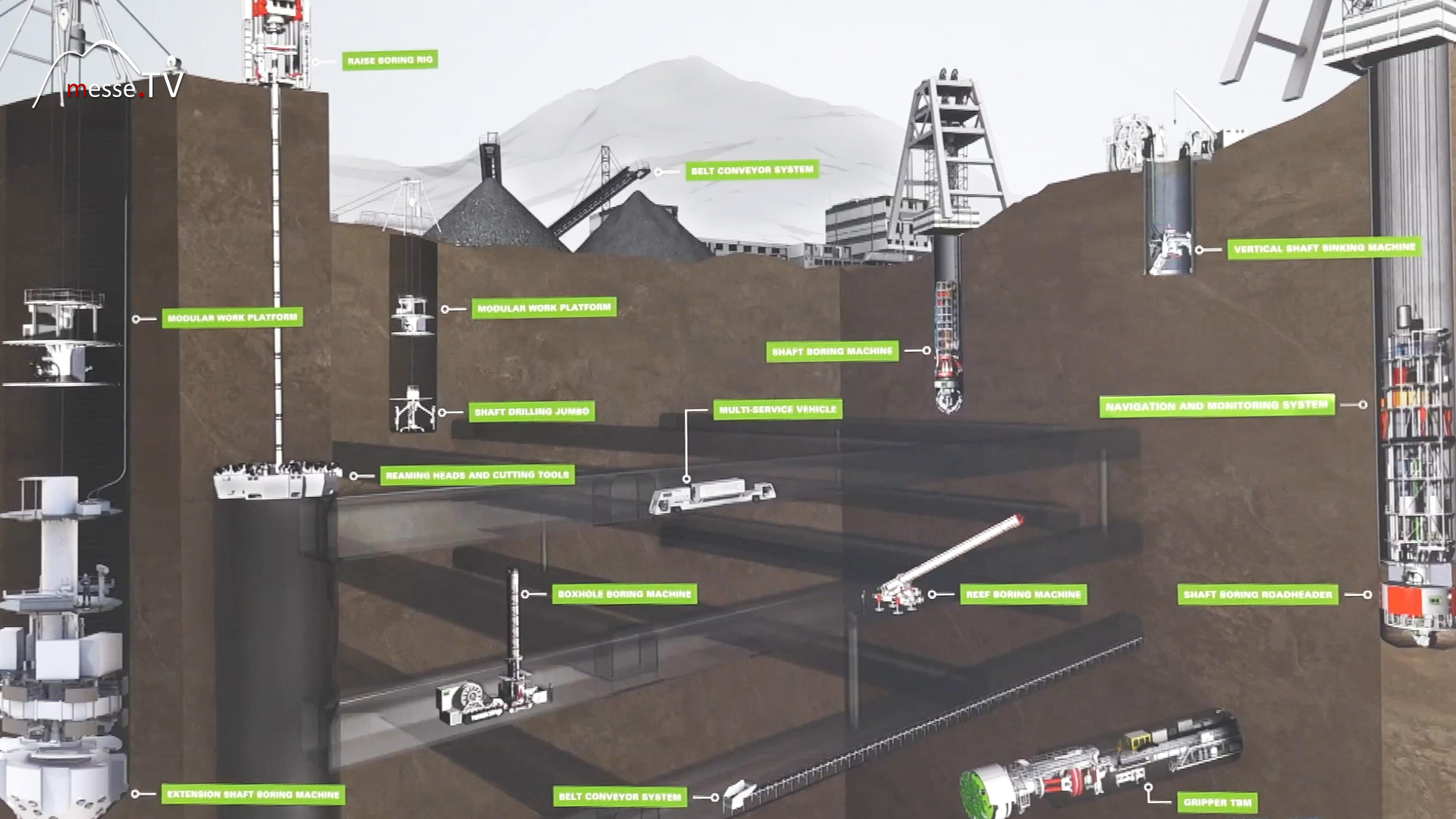

Felix Rother: We see that Herrenknecht does pretty much everything in underground construction. Or what exactly does Herrenknecht do? Stefan Hotz: In general, it's about drilling holes underground, and we do that in all dimensions and in all directions. And you can see that here in this overview diagram. You can see the various applications we have for underground mining. Here, holes are drilled from the bottom to the top, in large dimensions. Here, for example, a so-called shaft is being sunk with a fully automatic shaft boring machine.

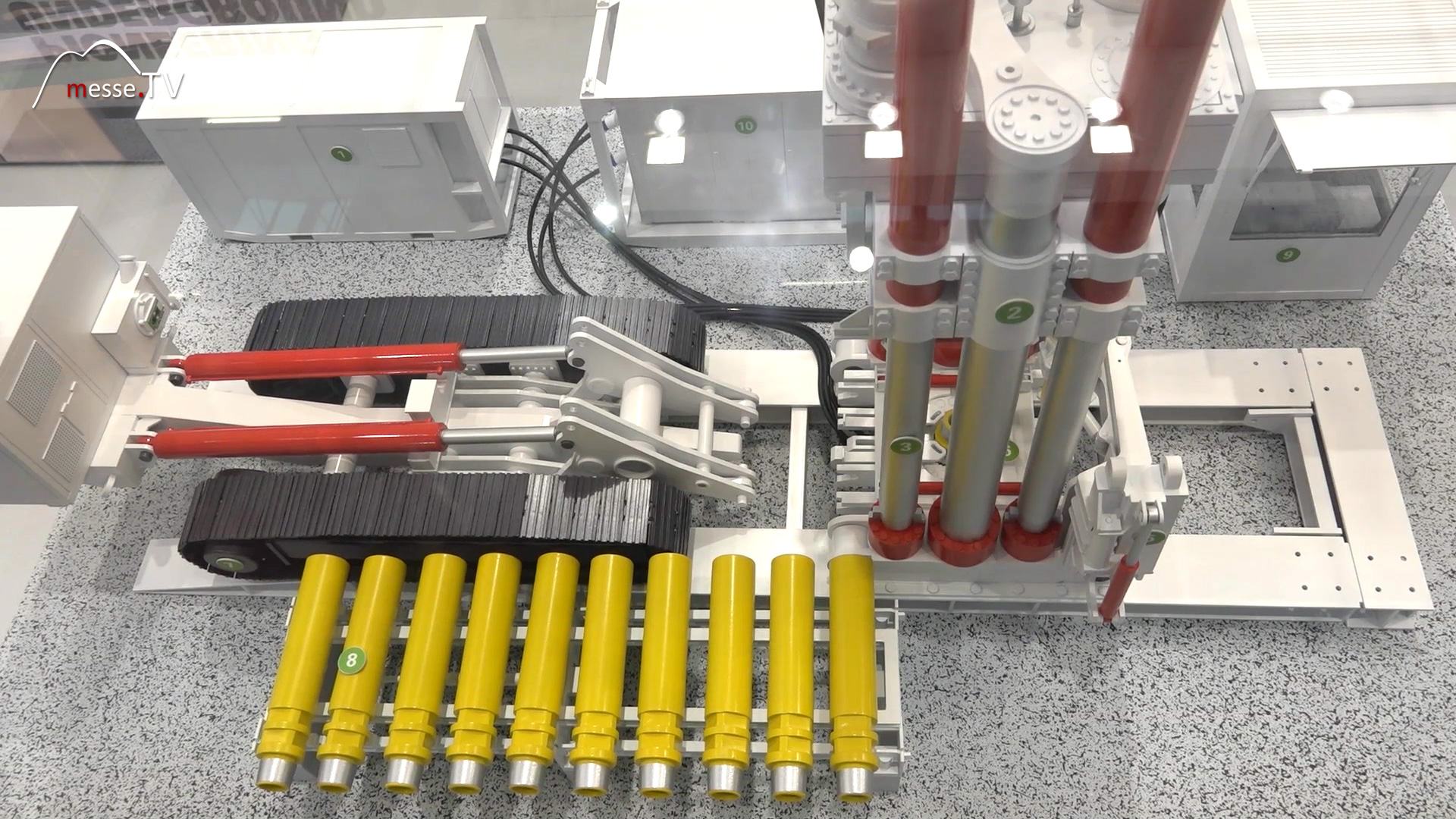

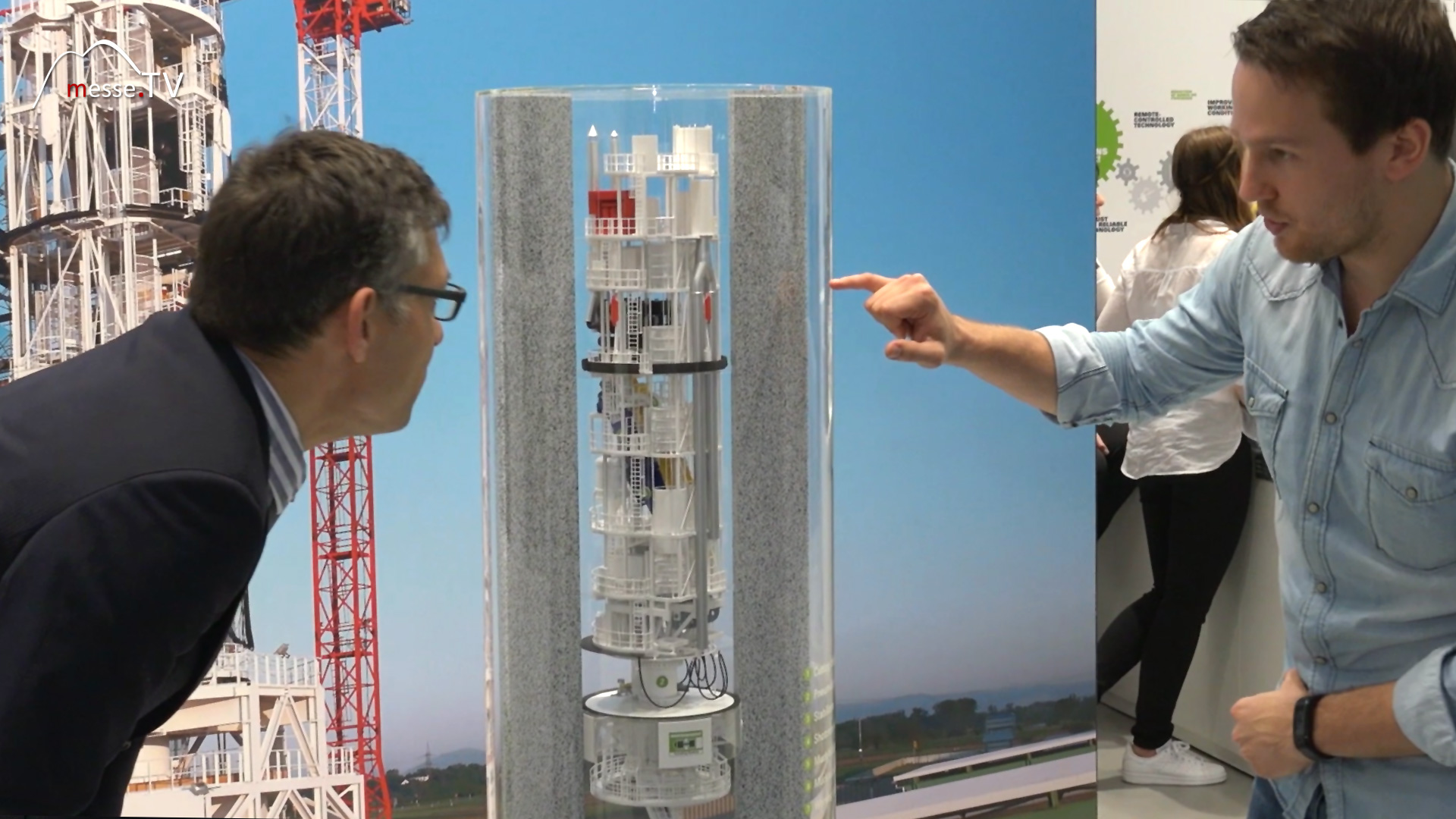

Felix Rother: Safety is a big issue in underground mining, can we perhaps take a look at that over there? Stefan Hotz: Yes, of course. Felix Rother: What do we see here now that really stands for safety - and what perhaps also defines Herrenknecht? Stefan Hotz: In general, I have a machine here to drill shafts, I drill from top to bottom. What we try to do is keep the people operating the machine out of the danger zone under the motto hands-off. In other words, there is a so-called automatic pipe handler here, which automatically takes these yellow parts upwards, backwards and inserts them into the machine. Felix Rother: In other words, the motto is hands off, so nothing can happen. Stefan Hotz: Hands off - people get out of the danger zone if they don't jump around, then they can't hurt themselves. And that's the idea behind it. Felix Rother: Now you've also said that the wreath lifts everything down here. How does that work - explain that to me again? Stefan Hotz: I drill from top to bottom over the entire distance - access is required from below - then the drill string comes down, I install this large ring and then I pull it upwards - with a lot of force and it rotates in the process. And through this turning process - there are still so-called roller bits at the top - I loosen the material, which falls away downwards. And then the whole thing is pulled upwards and that's how this shaft is created. Felix Rother: How big is this ring? How can we imagine it? Stefan Hotz: Well, it can be between 1.50 meters and 8-9 meters. So those are pretty decent dimensions and the length of this shaft can theoretically - if the geology plays along - be up to 1,500 - 2,000 meters.

Felix Rother: In theory, that means I can tear everything up to 2000 meters from below and it just trickles down! Stefan Hotz: Exactly. Yes, but as I said, geology is always important in mining. If it plays along. Felix Rother: I think there's also another machine over there. The big difference between this one and this one. Stefan Hotz: There are 2 differences. Firstly, if I don't have access from below, then I have to use a machine like this. Felix Rother: That means the machine is now from top to bottom - not from bottom to top. Stefan Hotz: Exactly, but this machine also goes from top to bottom and that's when I produce a so-called blind shaft. Here, the material has to be discharged from below via the shaft to the top. Felix Rother: Does that mean that there are always people on these intermediate levels? Stefan Hotz: Yes, exactly, there are people on these intermediate levels and they operate the individual areas, but the general rule here is also hands-off: Hands-off. There are no longer many people on the machine and again with the ulterior motive of keeping people away from dangerous processes so that they can't injure themselves and accidents can't happen. Felix Rother: In other words, hands off as far as possible. Stefan Hotz: Yes, exactly, hands off. There are actually two reasons for this. Firstly, because of the risk of accidents and secondly, as we said earlier in mining, it's also about saving costs. That there are fewer people in the machine. Felix Rother: So if you can summarize these concepts, you can say that it's about safety, of course it's always about costs and efficiency and it's about keeping people away to guarantee this safety. Where are we heading? Will it be possible to dig these holes from a distance of 10 kilometers so that nothing can really happen or where are we going? Stefan Hotz: Well, people can never be completely removed, but it is possible to move many monitoring processes away from the machine, for example. We have another application here, for example: from our office at home, we can see exactly what's going on in the machine via data transmission and the trend in mining is definitely towards greater automation and fewer and fewer people, that's right. Felix Rother: What's next in the future? Stefan Hotz: Well, I think we've laid the foundations for automation and now we're moving on to really reducing the number of people. That's one thing and the other, of course, is that it's always very important in mining to achieve the performance that the customer then demands. Felix Rother: Then I wish you and Herrenknecht the best of luck with networking and automation in order to be able to guarantee this safety in the future and thank you. Stefan Hotz: Yes, thank you very much!