Plöckl Media Group is now one of the leading international companies in the field of industrial labeling. RFID FlagTags are a key product in its portfolio. These have been continuously optimized in recent years and represent a practical solution for many industrial applications. FlagTags are available both pre-printed and blank. Users can print them themselves using standard RFID barcode printers, which allows for a high degree of flexibility. The adhesive-free area is particularly noteworthy: it makes handling easier when several thousand units have to be processed every day.

The technology also offers decisive advantages in environments that are problematic for classic RFID solutions. Liquids, metallized packaging, or blister cartons normally significantly impair readability. Thanks to the special design of the FlagTags, in which the antenna is positioned above the packaging, the signal quality remains stable even under these conditions. This means that even pharmaceutical products in blister packaging or tightly stacked metal plates can be reliably detected in bulk.

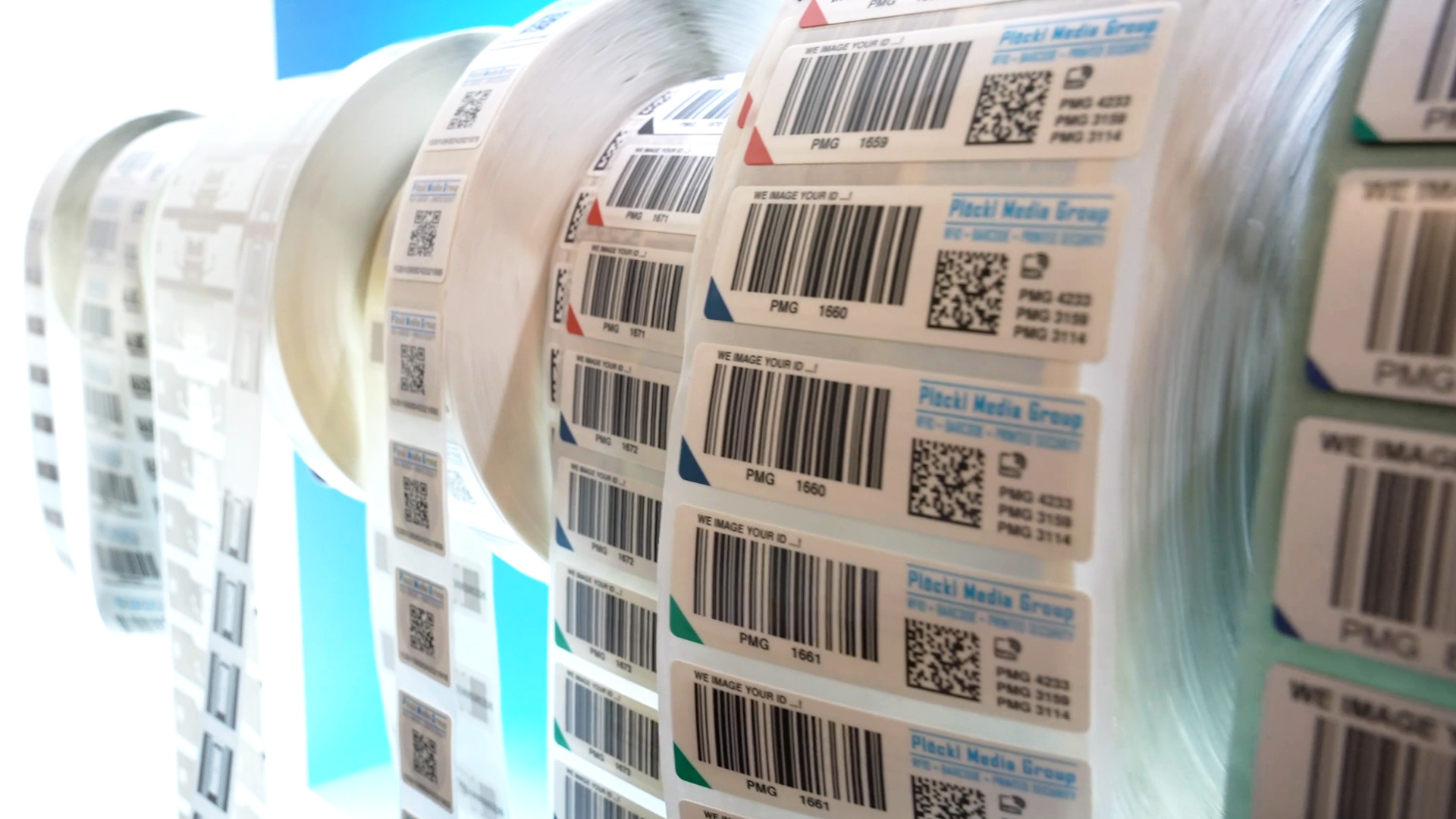

The company's philosophy is to adapt products to industrial processes—not the other way around. In industry in particular, it is hardly possible to change existing processes for new labeling solutions. That is why Plöckl Media Group creates customized labels that are tailored precisely to the needs of its customers. The portfolio comprises around 150 basic products, which can be quickly expanded to several hundred configurations through various variants. Differences include adhesives, temperature ranges, film types, print variants, and ranges. One customer may need RFID labels with a range of only three meters, while another may require twenty meters. This diversity allows us to meet a wide range of requirements in production, logistics, and warehousing.

A current focus is item tracking. This involves not only tracking pallets or containers, but also recording individual products at the item level. This opens up new possibilities, especially in sensitive industries such as pharmaceuticals and medical technology. The FlagTags can be linked to barcodes and attached to individual packages. In combination with so-called smart shelves or smart cabinets—usually metal cabinets in which medicines or other products are stored—the system automatically detects when an item is removed.

This removal is immediately registered, digitally recorded, and assigned to a shopping cart. Depending on demand, automatic reordering then takes place at fixed intervals. This means that stock levels are constantly updated without the need for manual Excel lists. The advantage is obvious: processes become more efficient, stocks remain transparent, and errors in documentation are eliminated. This represents a significant step forward, particularly in the medical environment, where it must be clear at all times which products are available.

The strength of the Plöckl Media Group lies in the combination of research, development, and production. Projects begin with a clearly defined specification sheet provided by the customer. Development work then begins, right down to the antenna and chip. Every detail is checked to ensure the desired performance. This close integration makes it possible to quickly put innovative solutions into practice. Customers benefit not only from the technology, but also from a competent partner who accompanies the entire process chain – from the idea to the prototype to series production.

With its RFID solutions, the Plöckl Media Group is making an important contribution to the digitalization of industrial processes. Automated product recording and complete traceability open up new opportunities in logistics, production, and trade. Whether it's the secure labeling of pharmaceutical items, the monitoring of ESD packaging with conductive coatings, or the recording of metallic components, the group's technologies prove their effectiveness in a wide variety of scenarios. This makes it clear that Plöckl Media Group is positioning itself as an innovation partner for companies that want to make their processes more efficient and secure. With an international presence, a broad product portfolio, and strong development capabilities, it demonstrates how industrial marking works in a connected world.