At Fachpack 2025 in Nuremberg, Beckhoff will be presenting the MX system: a modular platform that replaces the classic control cabinet with the same functionality and can be integrated directly into the machine frame. Plug in the modules, screw them in place, connect the plugs – the result is a ready-to-operate control and supply center with significantly fewer components, shorter assembly time and noticeably less space required.

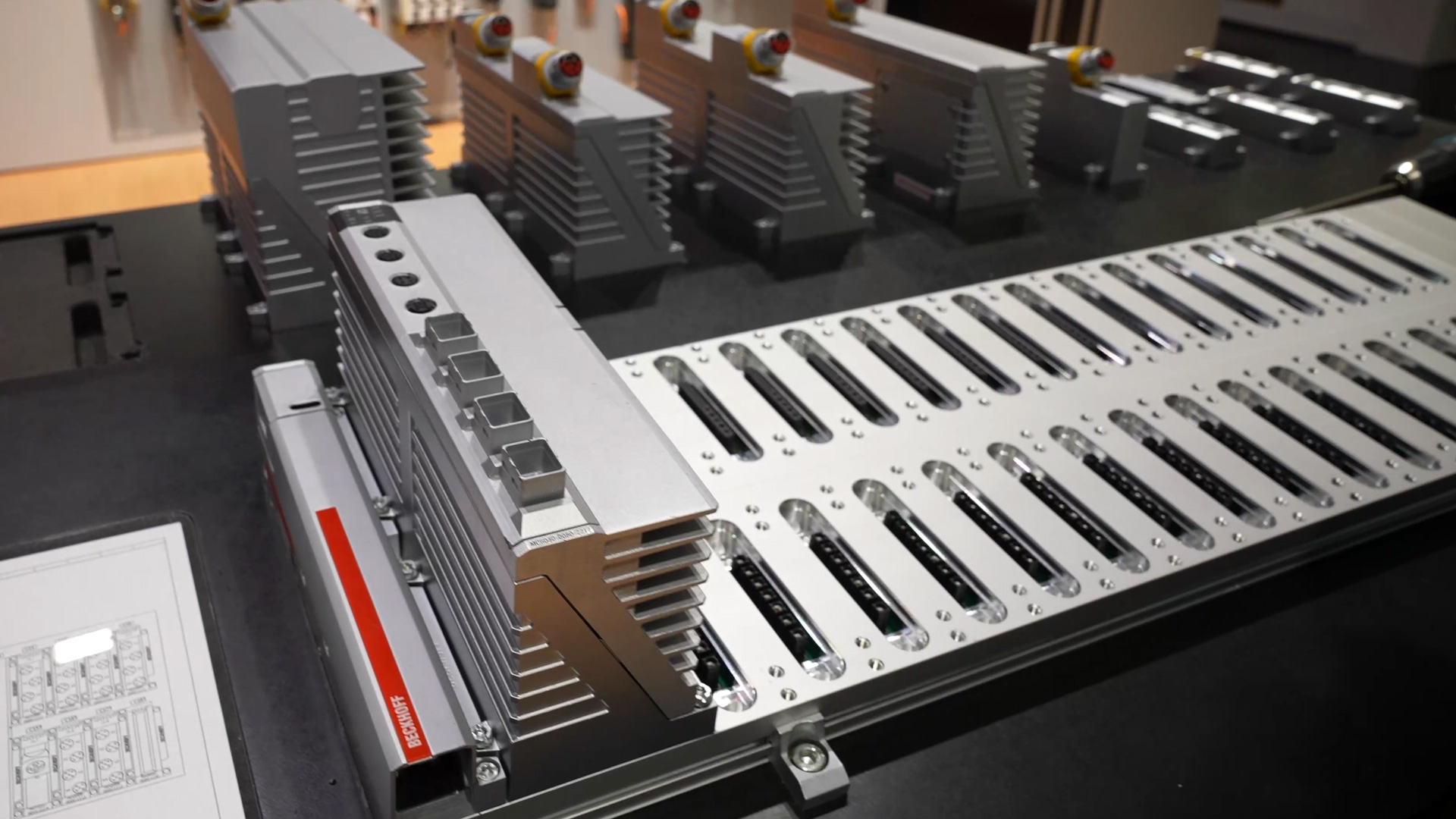

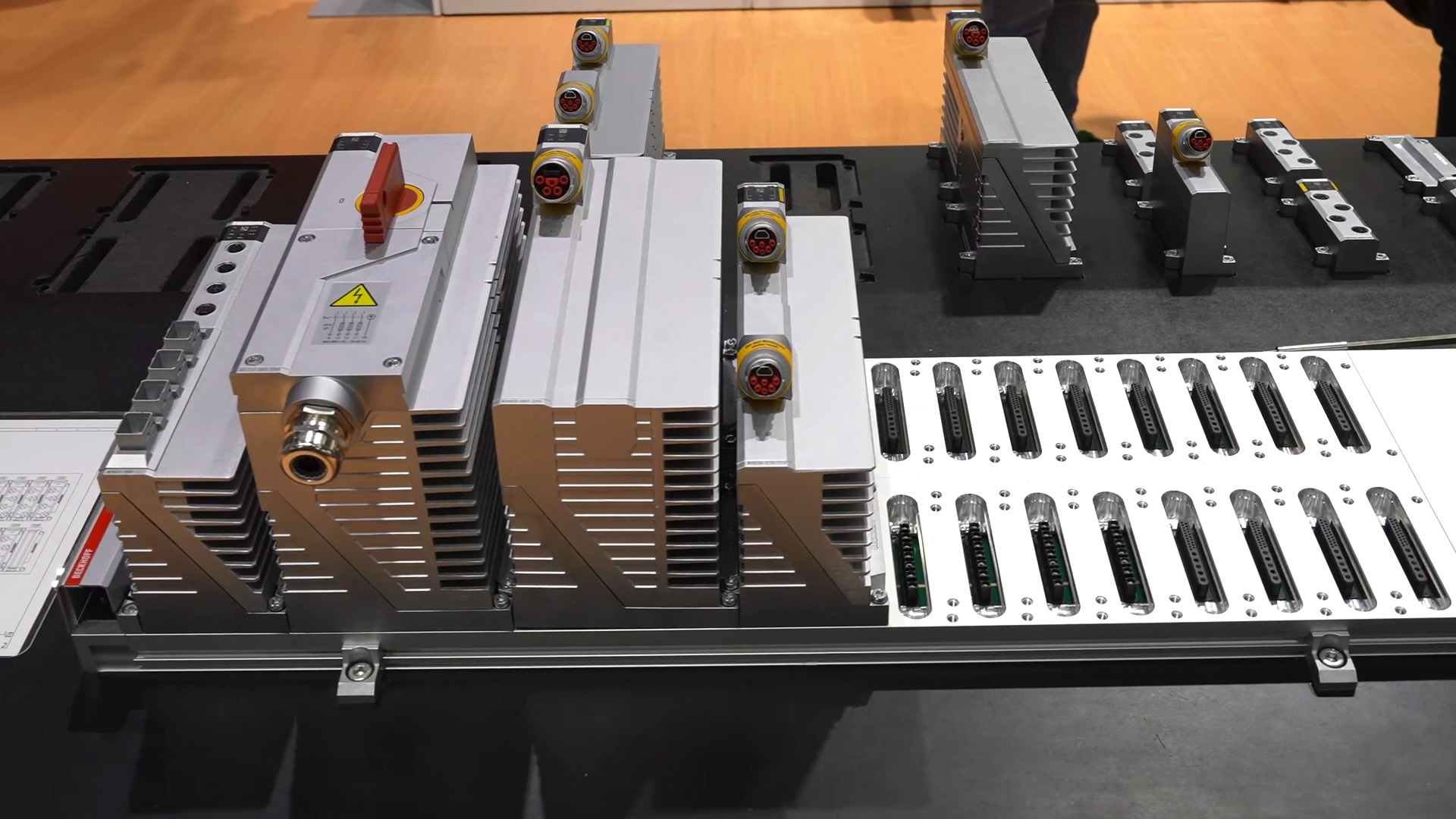

At the heart of the approach is the backplane, onto which function modules – for example, for power supply, control, drives, or I/O – are simply placed and fixed with a few screws. The time-consuming assembly and wiring of a control cabinet is no longer necessary.

The benefit lies in speed: shorter project times in engineering, faster commissioning, and fewer sources of error. Especially in times of skilled labor shortages, this is a measurable advantage for machine builders and operators.

Open terminal strips are replaced by pre-assembled connectors and cables. This makes assembly traceable, facilitates standardization, and lowers the entry barrier for teams without electrical certification. For users, this means less specialized knowledge for setup, clear interfaces, and consistently reproducible quality—from prototypes to series production.

Because the MX system is integrated into the machine, no separate control cabinet space is required. In many cases, even an air conditioning unit is not necessary. When servicing is required, the clear module structure ensures speed: remove the affected module, attach the replacement module, tighten eight screws, connect the motor cable – and the system is quickly back up and running. Fewer individual components also simplify diagnosis; downtimes are reduced and availability increases.

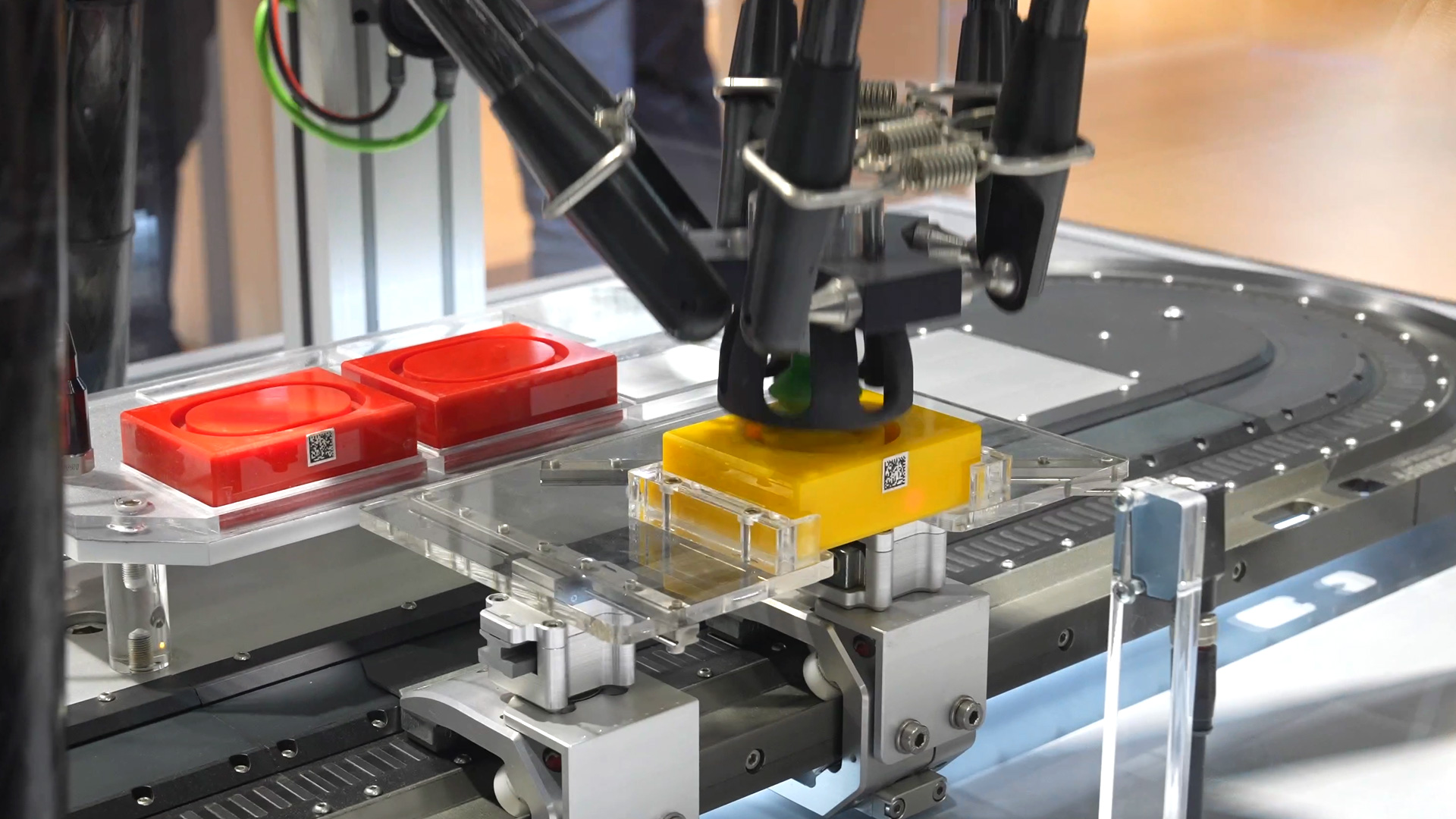

The system is aimed at “all types of machines,” with particular relevance in packaging technology. Special machine builders reduce their engineering time, large operators compensate for scarce service resources and ensure high uptimes. Beckhoff presents the appropriate portfolio: PC-based controllers in various form factors – from DIN rail PCs to MX system PCs – and comprehensive drive technology. In addition, the manufacturer demonstrates the intelligent transport systems XTS and XPlanar, which have become established as standard in many packaging lines and can be consistently combined with the MX system.

Beckhoff remains true to its open architecture and connects to numerous third-party systems. At the same time, there is a trend toward integrated systems: those who combine control, drive, transport, and power supply from a single source can reap the benefits of the platform, including in maintenance and service. The MX system is designed for this purpose.

A practical advantage: The MX system is designed to IP67. It can be mounted on the outside of the machine and is therefore insensitive to dust and moisture. A demo is running at the booth under light “water rain” – the modules continue to work. This underlines the claim to bring control cabinet functions to where they are needed, without additional housings and without air conditioning.

Beckhoff has its roots in control cabinet construction and is now known for PC-based control technology. These two worlds come together in the MX system: mechanically robust, electrically cleanly integrated, and software-integrated into the automation environment.

For machine builders and operators, this creates a building block that not only replaces the control cabinet, but also rethinks it – modular, maintenance-friendly, and optimized for availability. The result: less planning and installation effort, faster commissioning, simpler service scenarios, and a compact footprint on the machine. This is precisely what the Fachpack presentation aims to achieve: control cabinet functionality as a pluggable system – with consistently practical benefits from design to operation.