Fiber-based packaging is at the heart of modern sustainability strategies. With its thermoformable packaging, MM Board & Paper presents a solution that combines ecological responsibility and high product quality. The possible applications range from food and pharmaceuticals to fragrances and other industries.

The MM molds developed by MM Board & Paper are made entirely from cellulose. The basis is wood, which is processed into wood chips at the company's own pulp mill in Poland and then refined into high-quality pulp. A mixture of different types of pulp is used to create a formula that is precisely tailored to customer requirements. The products are given their final shape using a thermoforming process. This closed production process allows for seamless control over quality and sustainability. A key feature is the use of fresh fibers. This makes the packaging suitable for direct contact with food. At the same time, colored packaging components can be developed to match brand identities. The combination of functionality, safety, and design makes 3D packaging a flexible solution for a wide range of industries.

Production begins with the raw material wood. Over several stages—from chipping to pulp production to thermoforming—the material is processed so that it can be turned into high-quality packaging. The production facilities are designed for parts up to a size of 70 to 80 centimeters. This allows both small packaging units and larger components to be produced, as long as the design guidelines for stability and feasibility are adhered to. The value chain remains entirely in our own hands. This not only ensures transparency, but also adaptability: customer requirements can be quickly translated into specific formulations and shapes.

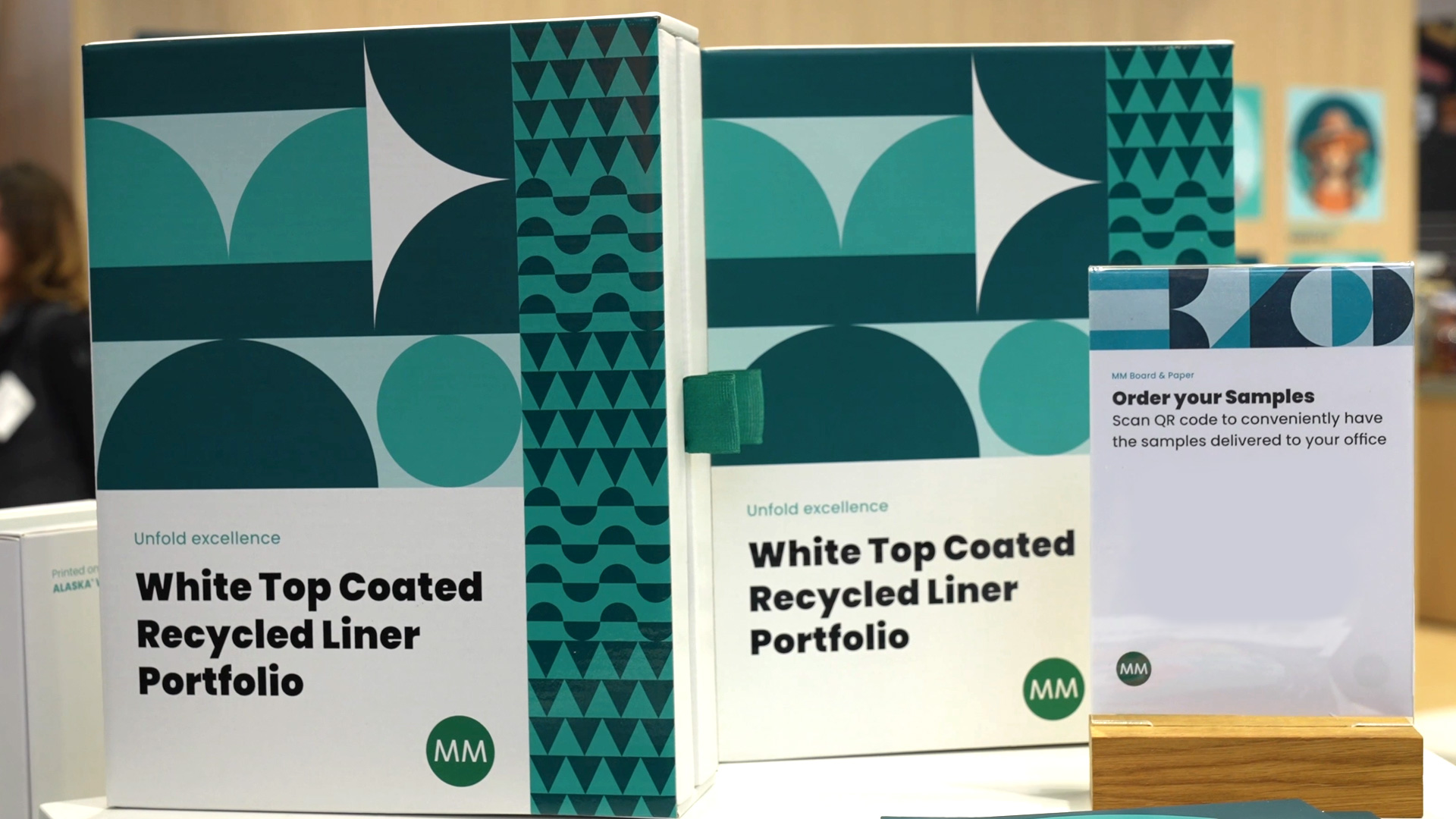

In addition to thermoformable packaging, MM Board & Paper offers a wide range of cardboard and paper qualities. The portfolio ranges from recycled cardboard to virgin fiber cardboard. It covers the liner sector for laminating corrugated cardboard as well as applications for copy paper, kraft paper, and special pharmaceutical papers. One special product is leaflet paper, which is used for package inserts in the pharmaceutical industry. Thin print qualities between 42 and 50 grams per square meter enable space-saving yet stable package inserts.

In addition, kraft papers weighing 70 to 80 grams and cardboard grades weighing 180 grams and above are available. This means that both lightweight print products and robust packaging can be covered. The company supplies formats for offset printing as well as rolls for gravure and flexographic printing. Although formats dominate in Europe, flexibility is maintained. For customers, this means that a single supplier can meet almost all common market needs.

MM Board & Paper is one of the few suppliers in Europe that combines recycled and fresh fiber cardboard in this range. This unique position allows the company to respond to market trends such as the growing demand for recycling solutions as well as the demand for high-quality virgin fiber packaging. Production capacity is around 1.2 million tons per year. Several board machines run continuously – 24 hours a day, throughout the year, interrupted only by necessary maintenance stops. A single machine can produce up to 600 tons of cardboard per day.

With its combination of sustainable 3D packaging, a comprehensive range of cardboard and paper products, and high-performance production, MM Board & Paper has positioned itself as a one-stop shop for a variety of industries. The pharmaceutical industry in particular benefits from the ability to source packaging, package insert paper, and cardboard solutions from a single source. However, food manufacturers and brand owners in other industries also take advantage of the benefits of end-to-end value creation. The combination of sustainability, material diversity, and production reliability makes MM Board & Paper a partner that combines environmental responsibility with market-oriented performance.