The SoniXs MCB-3 sets new standards in inline strapping. With a cycle rate of 36 packages per minute, an integrated digitization package, and innovative double pusher technology, the machine combines maximum efficiency with future-oriented technology. It will be available on the market from January 2026 and is already considered the new benchmark in packaging automation.

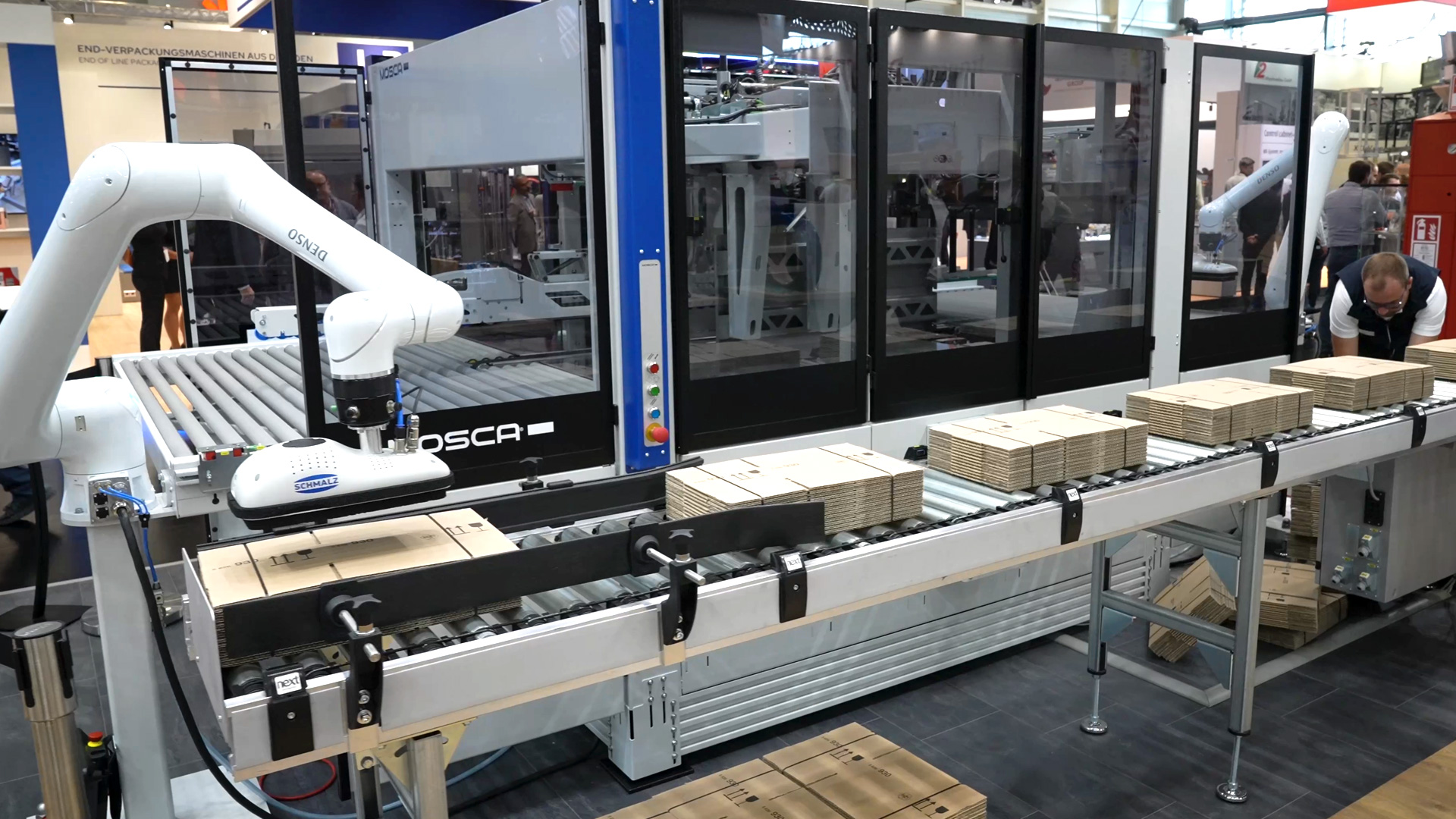

Mosca unveiled the SoniXs MCB-3 for the first time – an inline strapping machine specially developed for use behind fully automatic corrugated cardboard systems. With a speed of 36 cycles per minute, it achieves a level of performance that was previously unattainable. Crucially, the machine does not become a bottleneck for the entire system, but rather maximizes its output.

A central element of the SoniXs MCB-3 is the digitization package. This allows customers to read all performance-related key figures directly from the machine and integrate them into their production control system. This data opens up new possibilities for process optimization and creates transparency regarding efficiency, utilization, and maintenance requirements. Mosca thus makes it clear that the future of packaging technology lies not only in higher speeds, but also in smarter data usage.

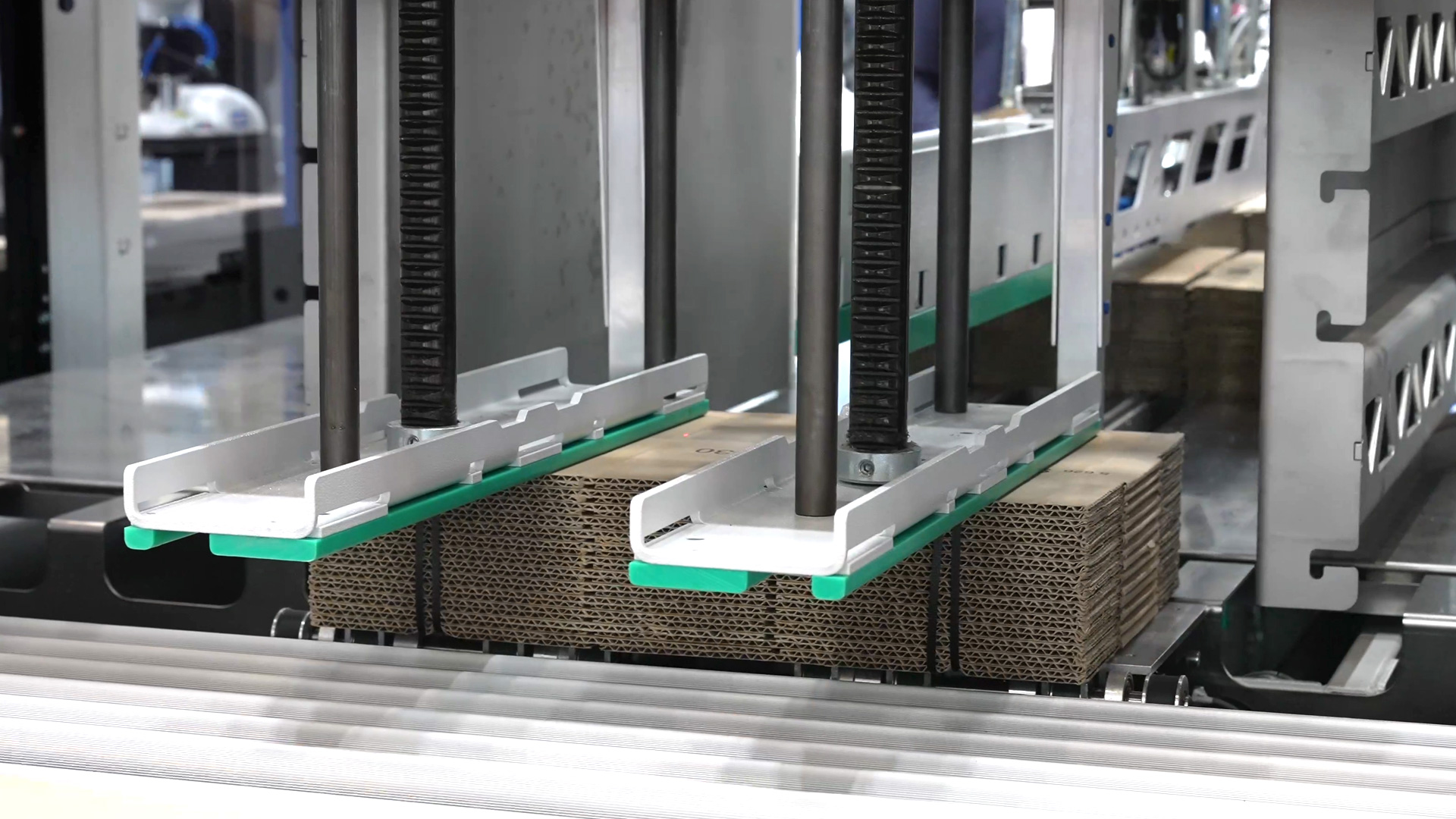

In order to achieve high cycle rates, the machine was equipped with a newly developed double pusher system. This system works independently and allows the next package to be ready while the previous one is still being processed. This ensures seamless operations without delays. Thanks to this solution, the speed could be increased to 36 cycles per minute.

Although the SoniXs MCB-3 is primarily designed for the corrugated cardboard industry, the technology is also used in other industries. These include the food industry, the building materials industry, and wood processing. Mosca offers a comprehensive portfolio – from hand-held devices and compact tabletop machines to large packing presses that strap entire pallets. Stretch wrappers and special solutions are also part of the range. Depending on the application, strapping can be used for bundling, as a carrying aid or as a closure security measure, for example in the pharmaceutical industry.

In addition to innovative products, Mosca attaches great importance to comprehensive customer service. After the installation of a system, service teams, consumables supply, and technical support are available worldwide around the clock. This service concept sets the company apart from many of its competitors and strengthens its position as a reliable partner to the industry. Customers thus benefit not only from a technologically leading product, but also from long-term support and security of supply.

Development of the SoniXs MCB-3 began early on and went through several concept phases. With its combination of speed, digitalization, and service quality, Mosca is clearly positioning itself as an innovation leader and setting the benchmark for future developments in packaging automation.