At EMO 2025, Rondo Ganahl AG will demonstrate how the circular economy works in practice: from collecting waste paper to producing its own paper to finished, custom-fit packaging. The focus is on corrugated cardboard with internal printing and dimensionally stable fiber-molded inserts that replace plastic and polystyrene – as mono-material solutions that can be completely recycled.

Rondo covers the entire value chain: waste paper is collected, processed in its own paper mill, and then converted into corrugated cardboard and molded parts. This “one-stop” approach not only ensures short distances and high process reliability, but also enables consistent CO₂ and PCF calculations across all stages.

A unique technical feature is corrugated cardboard with internal and external printing in a single run. This creates stable outer packaging with a functional interior layout (labeling, insertion instructions, branding) without any additional process steps. This saves time, prevents tolerance errors, and improves information management directly on the packaging.

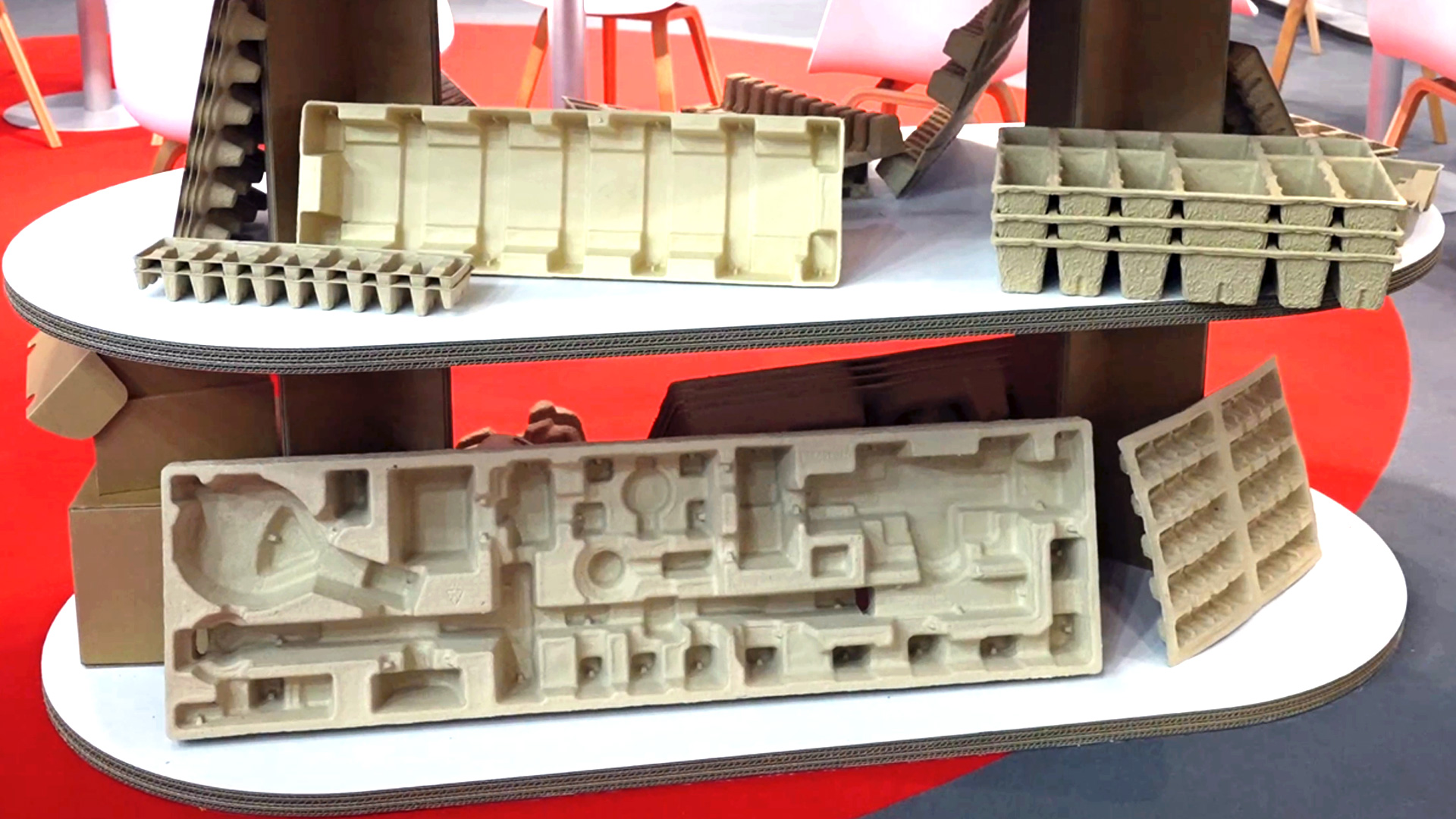

Rondo has been expanding its fiber casting segment for around five to six years. The molded fiber parts replace plastic blisters or Styrofoam padding – for example, in helmets, tube trays, or sensitive measuring devices. The inserts are made of monomaterial based on recycled paper, can be completely disposed of in the paper bin, and close the material cycle back to paper fiber.

With a view to the upcoming EU Packaging Regulation (PPWR), Rondo is addressing key requirements ahead of schedule: higher recycling rates, design for recycling, and the replacement of plastic where technically feasible. Monomaterial packaging made from fiber simplifies sorting, increases the material recycling rate, and reduces regulatory risks in future product portfolios.

The ecological difference starts with the raw material: paper fibers are based on renewable wood, while plastics are based on non-renewable sources. Rondo emphasizes this systemic advantage—supplemented by the ability to reliably report CO₂ and PCF values. This means that sustainability is not just claimed, but made quantifiable throughout the process.

Fiber-cast inserts can be stacked inside each other. Compared to bulky polystyrene blocks, significantly more sets fit on a pallet – depending on the application, by orders of magnitude more. This reduces storage and transport volumes, reduces truck trips and thus costs and emissions. In addition, the precisely fitting shape minimizes the risk of transport damage.

The industry focus is deliberately broad – the technical requirements are what matter. Whether coffee machines, safety helmets, or flow meters: combinations of printed corrugated cardboard and fiber-cast inlays secure the goods, dissipate forces, and reliably protect sensitive components – completely without plastic.

What is special is the depth of the system: Rondo produces outer cartons (corrugated cardboard), inner components (fiber casting), and the necessary raw materials in its own paper mill. This bundling enables tailor-made solutions, short development cycles, and stable supply chains – “everything from a single source,” from fiber input to ready-to-use packaging.