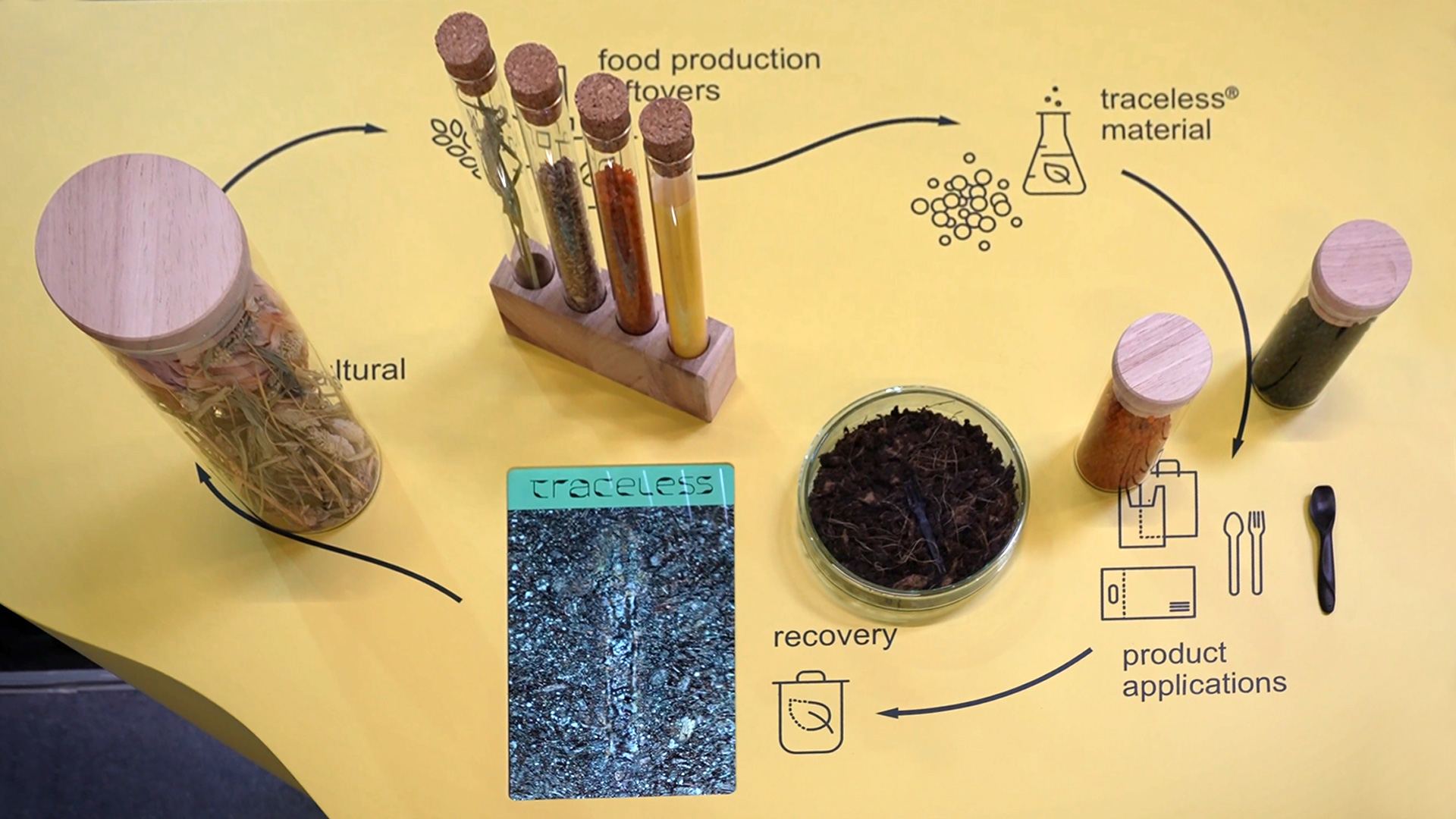

A company from northern Germany has set itself the task of developing a material that is produced entirely according to the principles of the cradle-to-cradle principle. From the outset, the aim was to avoid using any materials that cannot be returned to the natural cycle. The material is manufactured in a resource-efficient manner, requires significantly less energy in production, and is free of harmful additives. The result is a solution that is not only sustainable but also has a CO₂-negative balance—from raw material extraction to leaving the company premises.

The material has a special feature: it binds more CO₂ than is produced during its manufacture. Emissions are not only avoided during production, but also reduced on a net basis. It also differs fundamentally from fossil-based plastics in terms of recycling. During incineration, only the CO₂ that the plants used previously stored is released. This means that the climate balance is neutral – comparable to the combustion of an apple or other organic materials. The material can therefore be disposed of without any negative impact on the environment.

Although the material is home compostable, it cannot currently be disposed of in the organic waste bin. The reason for this is the regulatory classification, which dates back to the days of problematic bioplastic bags. Technically, decomposition in industrial compost would be possible, but this is not yet permitted by law. As a result, the material currently ends up mostly in the paper bin, where it is sorted out in recycling plants and then incinerated in a climate-neutral manner. It does not interfere with existing processes in residual waste or yellow bags either. The company's goal is to achieve recognition as a separate material class so that disposal can be made easier and more sustainable in the long term.

Founded in 2020, the company has now raised more than €36 million in Series A financing and is growing rapidly. A new production facility near Hamburg is set to produce several thousand tons of the material in the future. The start-up has long since become a scale-up with over a hundred employees, which is now taking the step into industrial production and broad market launch.

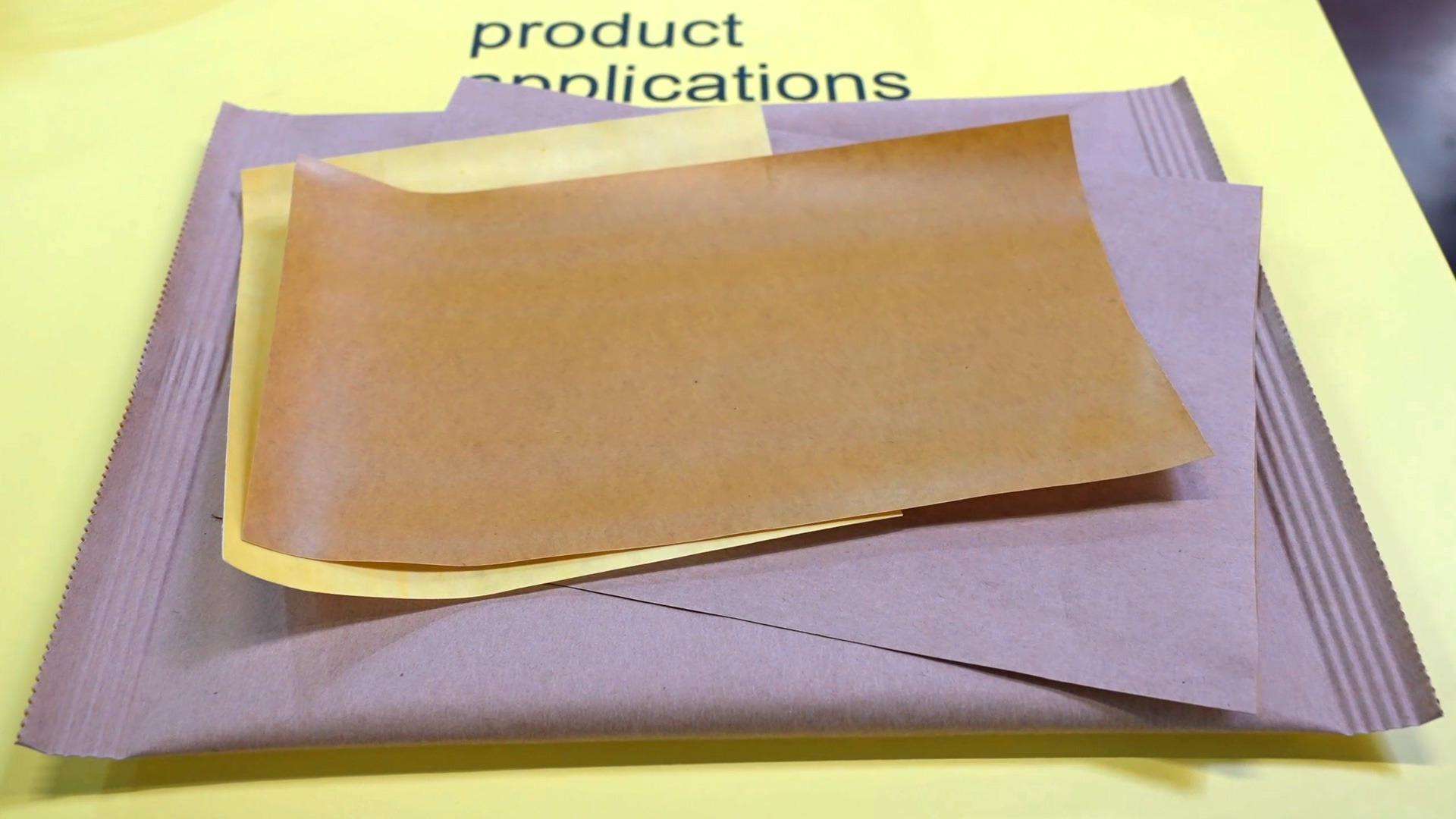

The versatility of the material is evident in numerous projects. The company is collaborating with Mondi on paper coating and with the manufacturer Hartl on injection molding. Retail companies such as Otto are also among the early partners. This collaboration is resulting in practical solutions for various industries that can replace fossil-based plastics. With growing production capacity, broad market launch is approaching—a step that is of great ecological and economic significance.