Fanuc is demonstrating how closely robotics, automation, and artificial intelligence are now interlinked with a wide range of new developments at the automatica. It's not just about higher payloads or faster movements—it's about how systems can become smarter, more flexible, and easier to use at the same time.

A central exhibit is the M-410 palletizer. Designed for loads of up to 800 kilograms with a reach of approximately 3.20 meters, the system is aimed at heavy-duty logistics. However, its special feature lies less in its mechanics than in its control system: With the new A-50 and the integration of the Standard Robot Command Interface (SRCI), the robot can be controlled directly from the Siemens TIA Portal.

Programming knowledge from the classic robot world is not absolutely necessary for this. Anyone familiar with PLC programming can configure the robot without any problems. This opens up completely new possibilities, especially for companies without their own robot specialists.

Another topic that Fanuc is addressing is the increasing role of AI in preventive maintenance. A dedicated application demonstrates how robots can be permanently monitored in a network. The system detects wear or impending failures at an early stage, before production comes to a standstill.

Planning is preventive, so to speak, and downtime can be almost completely avoided. This “zero downtime” concept, supported by AI-based analysis, is becoming increasingly important in industry.

In addition to the A-50, Fanuc is also showcasing the new R-50iA controller. It offers additional performance reserves, enhanced image processing functions, and an integrated energy-saving mode. Cybersecurity has also been consistently developed, which has become a critical factor in view of increasing networking in many production environments.

The controller is complemented by a newly designed teach pendant: 40 percent lighter, with improved haptics and even more intuitive operation. Those who prefer to configure their robots remotely can do so via the Remote Motion Interface. Fanuc thus offers a wide range of options to make getting started with robot programming even more flexible.

To provide customers with the best possible support in integrating these technologies, Fanuc operates a comprehensive training center in Neuhausen. In addition to modern training rooms, there are around 80 guest rooms and a hotel.

The entire portfolio is taught in a practical manner, from the basics of robot operation to complex advanced training courses. In addition, Fanuc offers regular webinars in the “TechTrends” series, which explain technical developments in an understandable way and provide in-depth information.

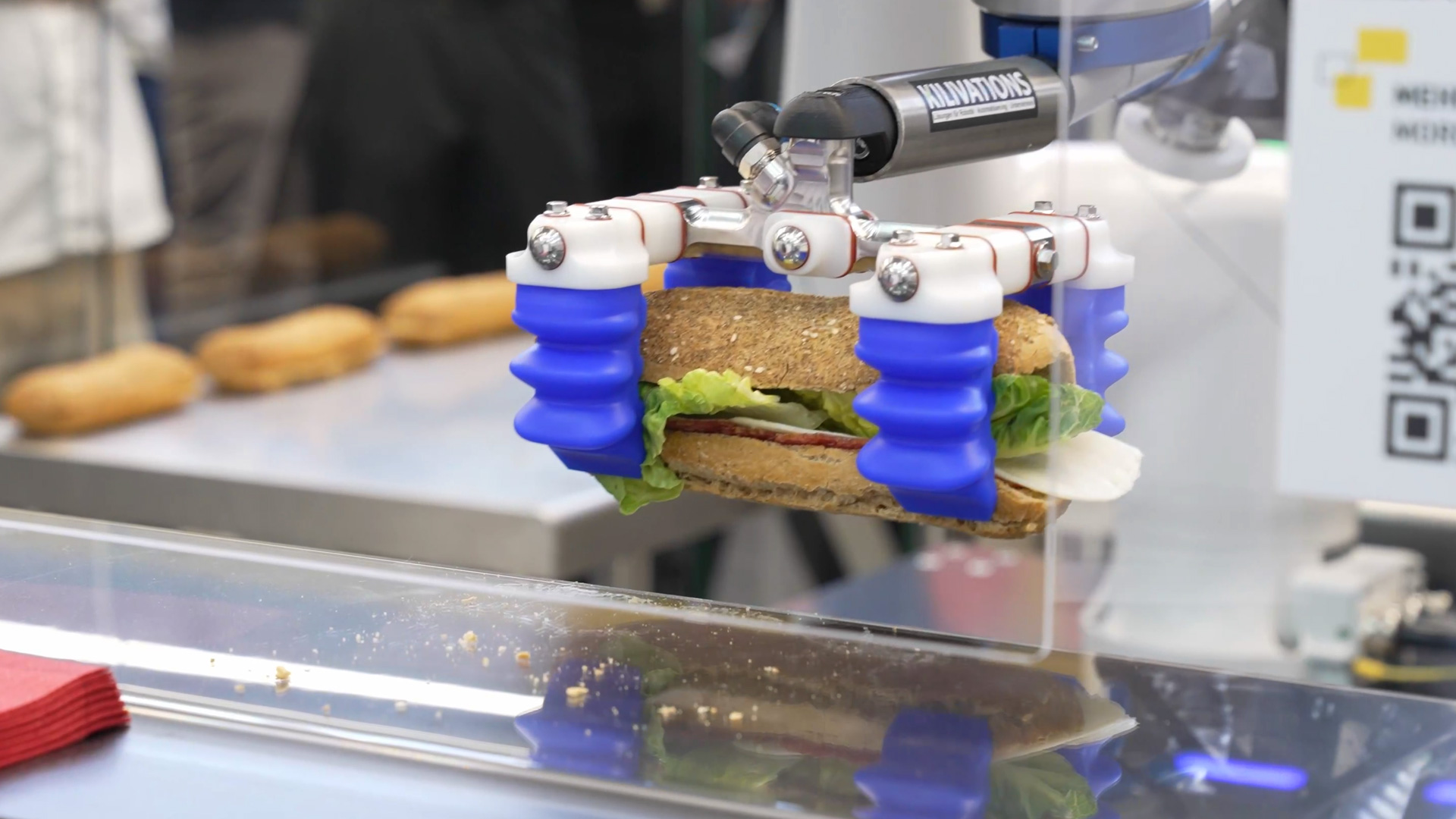

A particular focus is on the collaborative CRX robots, which are specially designed for the food industry. Food-grade grease is used in the axes, and the robots comply with all industry-specific certifications. Thanks to integrated force and human sensors, they react immediately to external influences and stop automatically when touched.

To illustrate this, Fanuc is presenting a practical scenario from food processing: Together with partner companies such as Bizerba, ViscoTec, Schmalz, and plant manufacturer Kilivations, it is demonstrating how rolls are filled automatically. A human places the rolls and adds lettuce leaves and other ingredients, while the robot dispenses remoulade and performs other filling tasks.

One detail catches the eye: a green status LED on the collaborative robots indicates when safe collaborative mode is active. Such visual indicators create confidence in the safety of the collaboration. The interaction between different technology partners also exemplifies how open interfaces can be used to automate entire lines – from cutting to dispensing.

The application presented is intended as a trade fair showcase. It illustrates the current possibilities, but also makes it clear that such systems can be developed significantly further. Through the targeted use of additional camera technology or advanced AI, such lines could be automated even more in the future. For now, however, the solution on display serves as an eye-catcher and a basis for discussion – a deliberately pragmatic approach to clearly conveying the benefits to customers.

Fanuc is opening up low-threshold access to automation, particularly for medium-sized companies that have previously shied away from complex automation solutions. In view of the ongoing shortage of skilled workers, such flexible systems are becoming increasingly attractive: they relieve the burden on existing staff, ensure consistent quality, and enable companies to remain competitive even with limited personnel resources.

Finally, Fanuc points to the dynamic developments of recent years. The past two to three years in particular have shown how rapidly the fusion of classic robot technology and learning systems is progressing.

What used to be separate worlds – mechanics here, software there – are increasingly growing together. Intelligent systems analyze data streams, independently adapt motion sequences, and continuously optimize processes. This makes automation not only more efficient, but also more robust and adaptable.