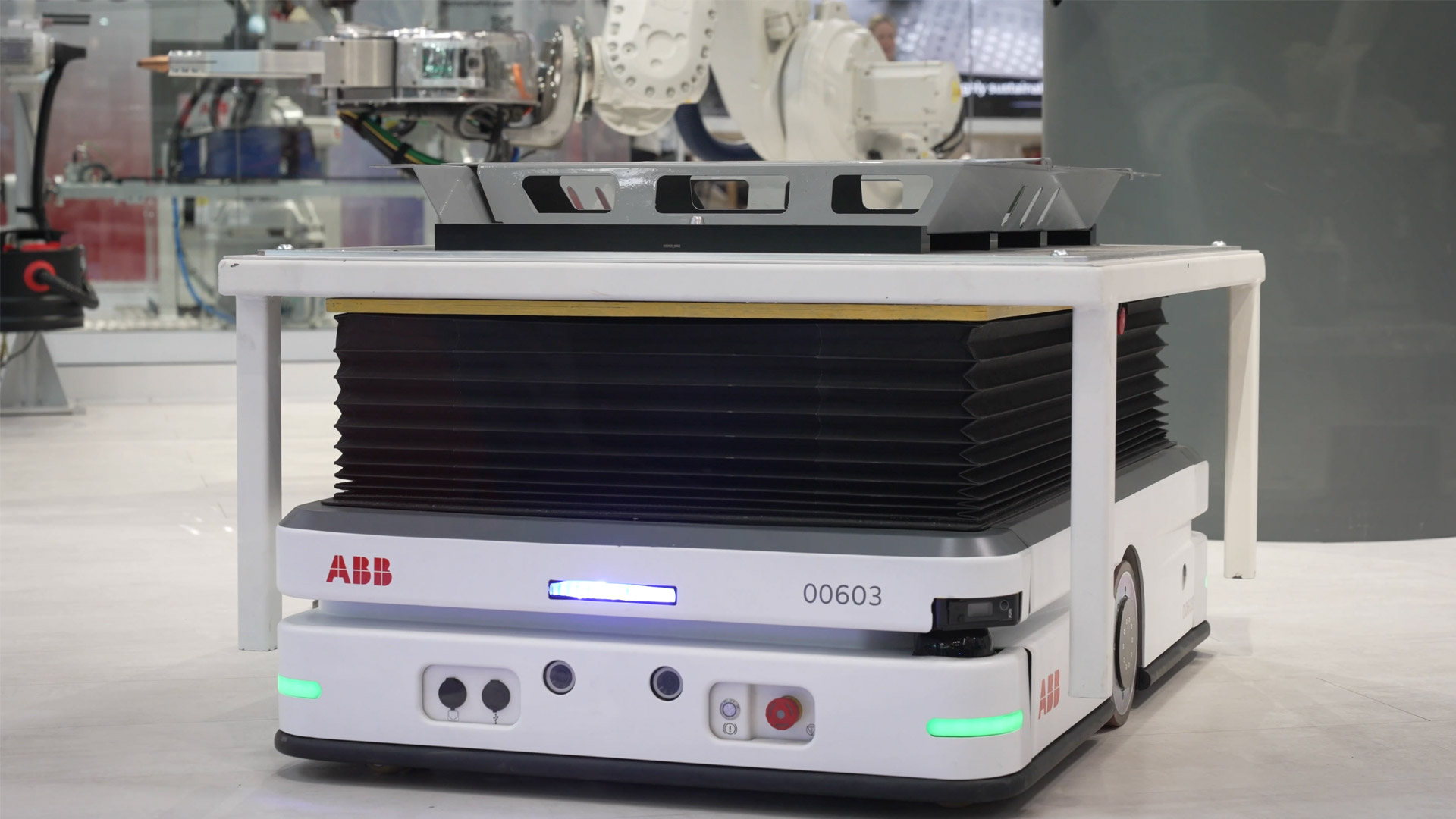

ABB is expanding its portfolio of autonomous mobile robots (AMR) with the new P603, which has been specially developed for intralogistics applications. The compact transport robot is equipped with Visual SLAM navigation and enables high-precision orientation in dynamic environments. Despite its small size, the P603 can move various loads, including pallets, open and closed containers, and racks up to 2.5 meters in length and weighing up to 1,500 kilograms.

A key feature of the P603 is its open interface for so-called top modules. This allows the robot to be flexibly adapted to individual applications. Together with ABB's software platform, users can easily program specific applications and integrate them into existing processes.

This means that the AMR is not only used to transport goods to the palletizer or depalletizer, but also connects storage areas directly to production lines or other automated and manual processes.

The P603 has a lift height of 160 millimeters, which makes it particularly ergonomic when employees work directly with the AMR. It also meets the highest safety standards: it stops reliably in front of obstacles and only continues its journey when the path is clear again. This ensures predictability and repeatability throughout the entire material flow.

The AMR Studio Fleet Manager can be used to control not only P603 models, but also other AMR types from ABB. These include the T702, a tow AMR, and the P604, another platform variant.

This allows different robot types to be combined within a fleet and tailored to a wide range of intralogistics tasks.

Thanks to Visual SLAM (V-SLAM), the AMR learns and understands its environment precisely. Unlike many other systems, the P603 stays on fixed routes to ensure punctuality, especially when carrying heavy loads.

At the same time, its special suspension allows it to be used on uneven or older floors, such as those often found in brownfields, i.e., existing industrial facilities. This reduces structural modifications and facilitates integration into existing production environments.

ABB is thus demonstrating how modern AMR technology scores not only in terms of load capacity and flexibility, but also in terms of sophisticated navigation, safety, and compatibility within mixed robot fleets.