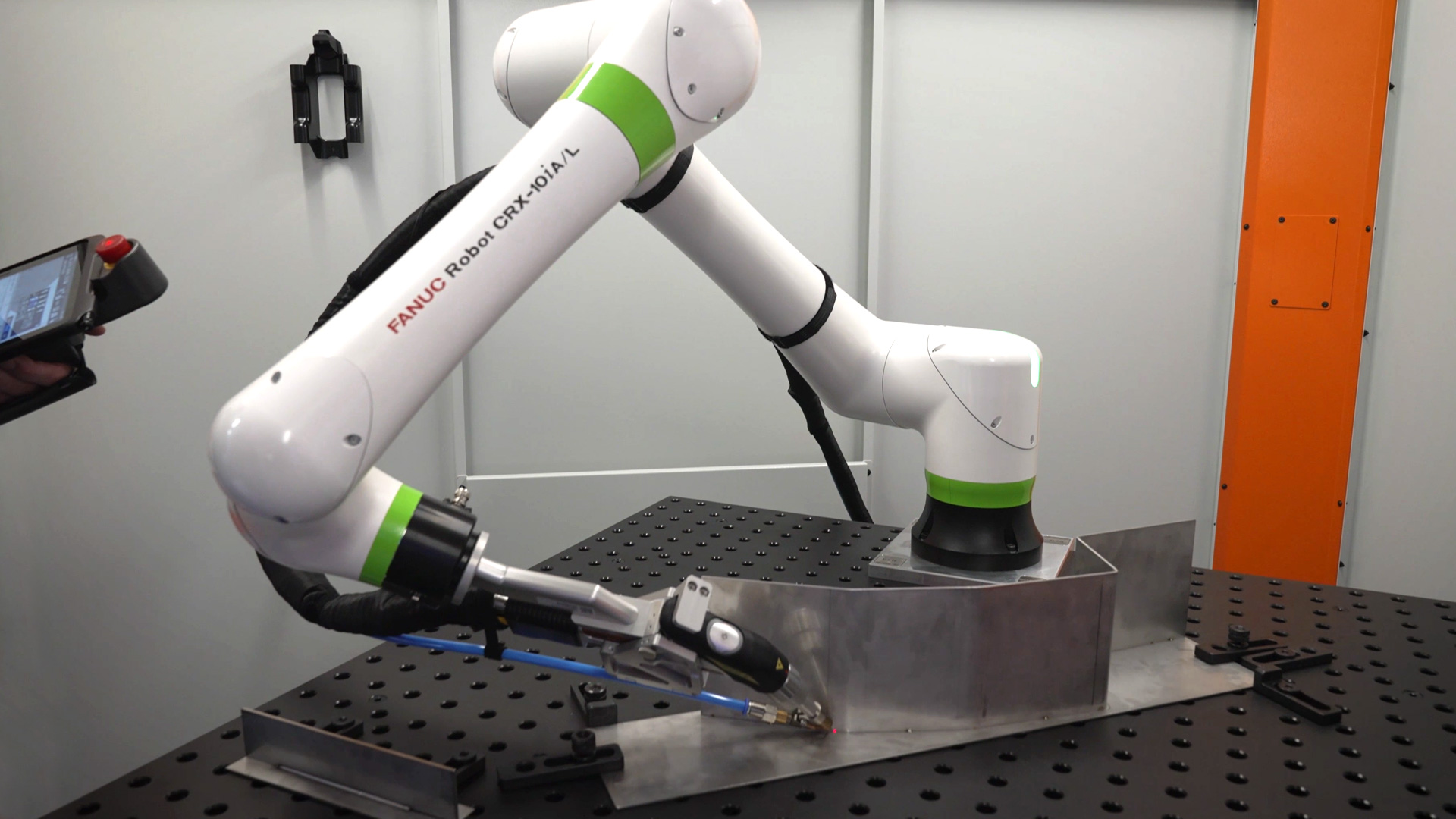

Guttroff is primarily known as a gas supplier, but at the trade fair it is demonstrating how broad its portfolio has become. In addition to gases, the company has its own automation department, where it is presenting a full-package system for laser welding.

This complete system includes all components required for automated welding processes: from the laser itself, to the power source and wire feed, to the robust welding cell.

At the heart of the system is a laser cell that houses all the technology. Visitors to the exhibition hall can see for themselves what the system looks like and how it works. Normally, such a cell is closed, as a class 4 laser is one of the most dangerous categories of laser there is.

The legal regulations, which are formulated by the employers' liability insurance association, among others, are correspondingly strict. These specifications are mandatory, not optional — they define exactly how a laser cell must be designed to protect operators and the environment. Guttroff strictly adheres to these safety standards, both as a manufacturer and in the individual design and integration of such systems.

A key feature of the system presented is its particularly easy handling. Instead of complicated software programming, users can guide the robot directly by hand. The “teach-by-hand” function allows the torch to be moved manually to the desired positions.

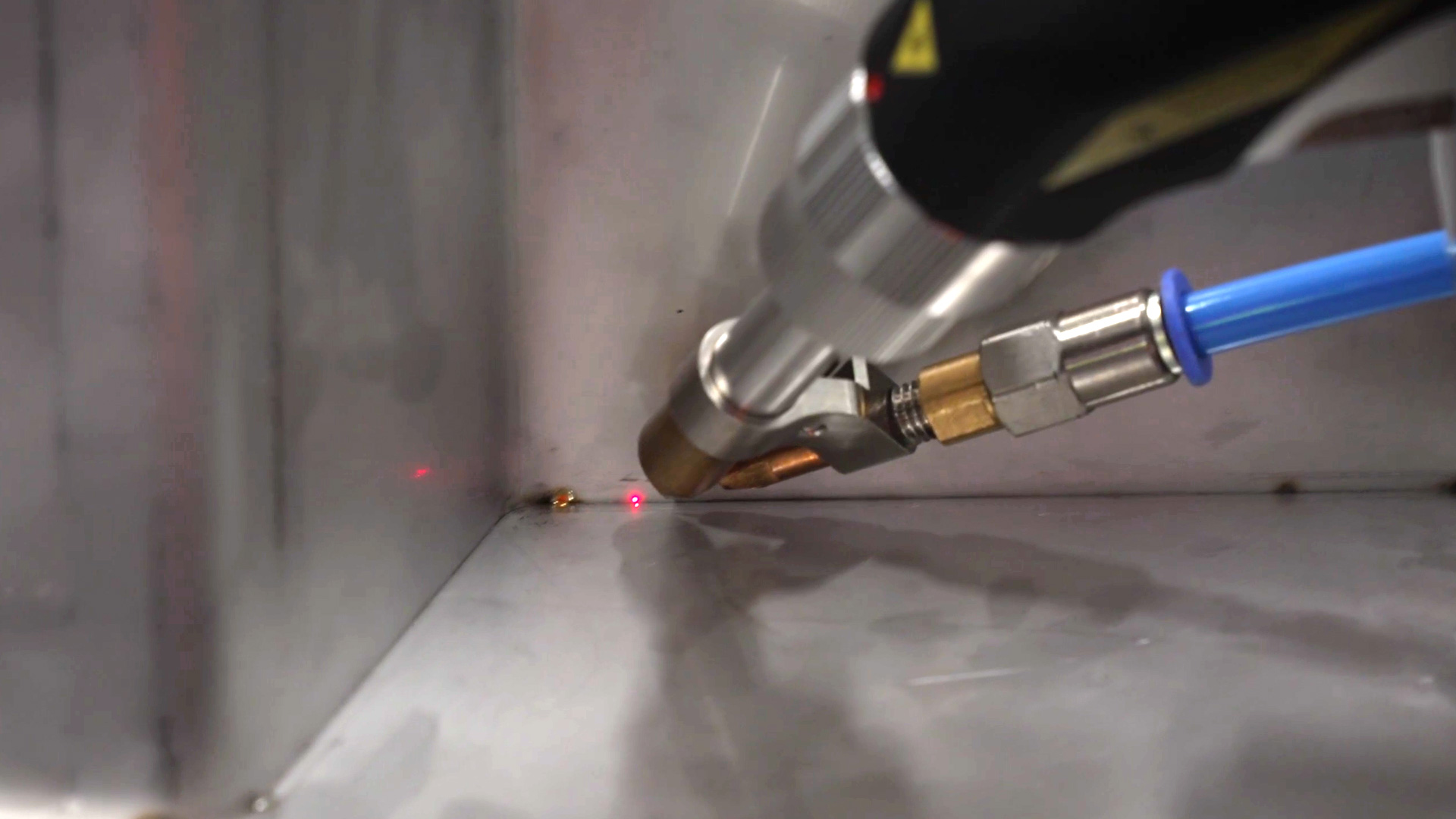

These points are stored by the system so that the cobot then independently follows the programmed paths and sets the weld seams. The starting point is entered via a touch panel, followed by further positions, creating a line that the system executes automatically. This keeps the learning curve for operating personnel low, which is a major advantage, especially in times of skilled labor shortages.

In addition to the standard cell for manual welding, Guttroff Laser also designs cells entirely according to customer requirements. If, for example, a company needs a system measuring five by eight meters, an internal design department takes care of the exact planning and layout.

An open design was deliberately chosen for the trade fair to provide insights into the inner workings of the cell and demonstrate to visitors how clean and safe the structure is. Normally, these side walls are closed so that no one is accidentally exposed to the laser during subsequent use.

Guttroff sees itself not only as a supplier, but also as a partner that supports its customers from the very beginning. Already in the planning phase, the company works with its customers to determine which solution makes sense and which details need to be taken into account.

The company develops concepts, proposes specific variants, and presents them to the customer in detail. From order to delivery to installation, Guttroff takes care of every step, sets up the system, and ensures that everything is ready for operation.

Another focus is on training and safety instructions. Especially for laser welding, a specially trained laser safety expert is required on site. Guttroff points this out early on and offers appropriate training. Even after commissioning, the company returns to the customer for follow-up training or refresher courses to ensure that everything continues to run smoothly even after months of operation.

The robot used is a collaborative robot (cobot) that not only works automatically but can also be easily moved by hand. If it is pushed away during operation, it stops immediately and remains stationary—an additional safety feature.

This allows operators to intervene at any time without having to perform time-consuming shutdowns or resets. The system also recognizes when the battery needs to be charged, automatically moves to the charging station, and then resumes operation.

Guttroff is thus appealing to companies that want to automate but do not necessarily have trained high-tech programmers. Welding paths can be set up intuitively via the touch panel: tap the starting point, define the end point, enter the material thickness, and the process starts.

With its full-service solutions, Guttroff offers much more than just gases or standard systems. The company plans, designs, and delivers complete laser cells that are individually tailored to specific requirements.

Safety plays just as important a role as ease of use. With comprehensive support ranging from consulting and training to after-sales service, Guttroff ensures that the systems are not only installed but can also be operated safely and sustainably.