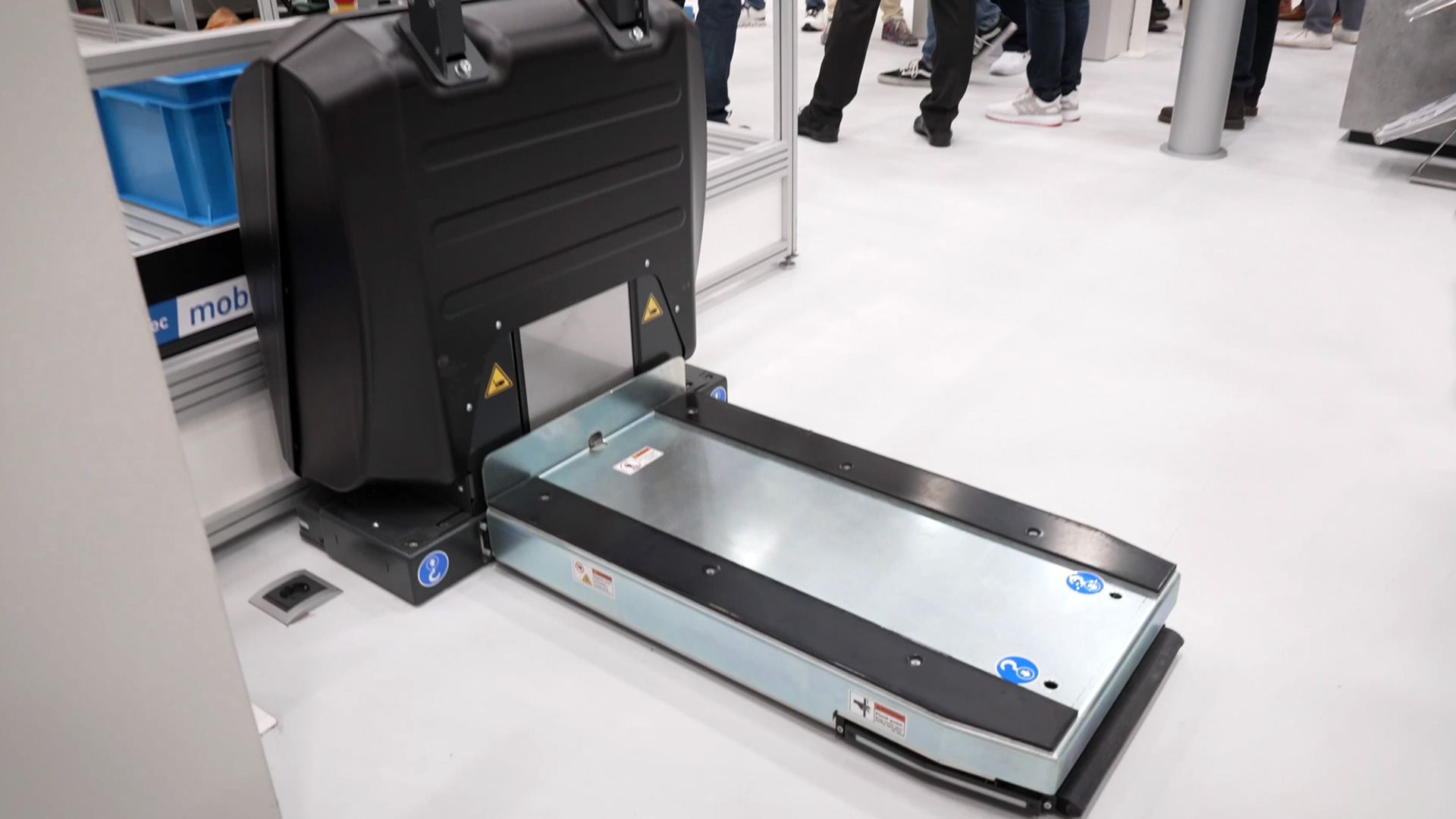

Omron is presenting its new OL-450S mobile robot at the trade fair. The vehicle is designed for autonomous material transport and moves independently through warehouses and production halls. With a load capacity of 450 kilograms and a speed of 1.2 meters per second, the OL-450S is particularly suitable for transporting trolleys and material containers within manufacturing or logistics areas.

The robot has a lifting height of 300 millimeters, which allows it to lift trolleys or other loads and position them precisely. Omron has equipped this model with 360-degree safety monitoring, which enables the system to react to obstacles at any time.

The OL-450S independently detects small changes in the environment and avoids them; for larger adjustments, the map is re-read or updated directly via the scanners. Alternatively, an existing DXF file of the hall layout can be imported into the system to define the travel paths.

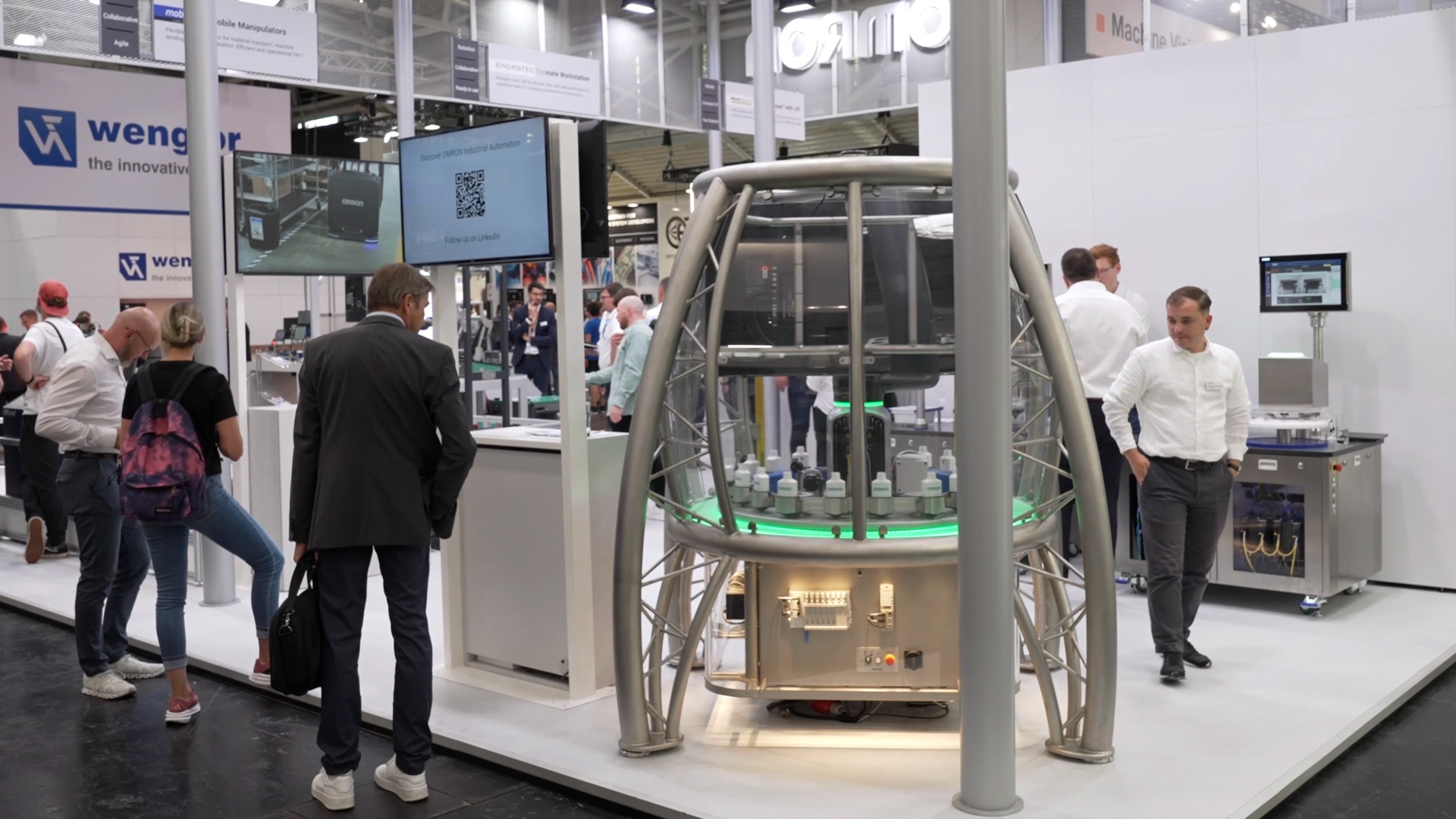

The primary areas of application for the OL-450S are in intralogistics. The system is highly flexible: whether in the food and consumer goods industry, the automotive sector, or in digital factories, the robot can be integrated across industries. With its portfolio, Omron essentially serves all areas that require automated transport.

A key difference between Omron and other providers is its wide range of models. In addition to the OL-450S, the company offers a complete fleet of other mobile robots with payloads ranging from 60 to 1,500 kilograms. The spectrum ranges from very small, compact vehicles to systems with high payloads, including special customer-specific superstructures.

All vehicles communicate via a central fleet manager that is connected to the customer's ERP system. This distributes transport orders so that the vehicle closest to the destination is always used. The system also takes load statuses into account and optimizes the deployment of the entire fleet.

Thanks to the network, each robot knows where the other vehicles are, and fleet management enables seamless monitoring of travel times and battery statuses.

The robots charge themselves: they recognize when their battery needs recharging, drive to the charging station independently, and start charging. Manual intervention is usually not necessary. However, if necessary, the vehicles can also be moved manually at any time—for example, in the event of a malfunction.

Omron emphasizes that there is often more to buying a mobile robot than just the hardware. Not every company has the necessary expertise to handle programming and integration in-house.

That is why Omron works with a comprehensive partner network that offers complete automation solutions, including installation and software customization. Omron considers this combination of technology and service to be a key differentiator from many of its competitors in the market.