Revolutionary robot control from Evasive Robotics

by A. Bergmeier - 2025-07-14Robots with emotions: An unusual trade fair appearance

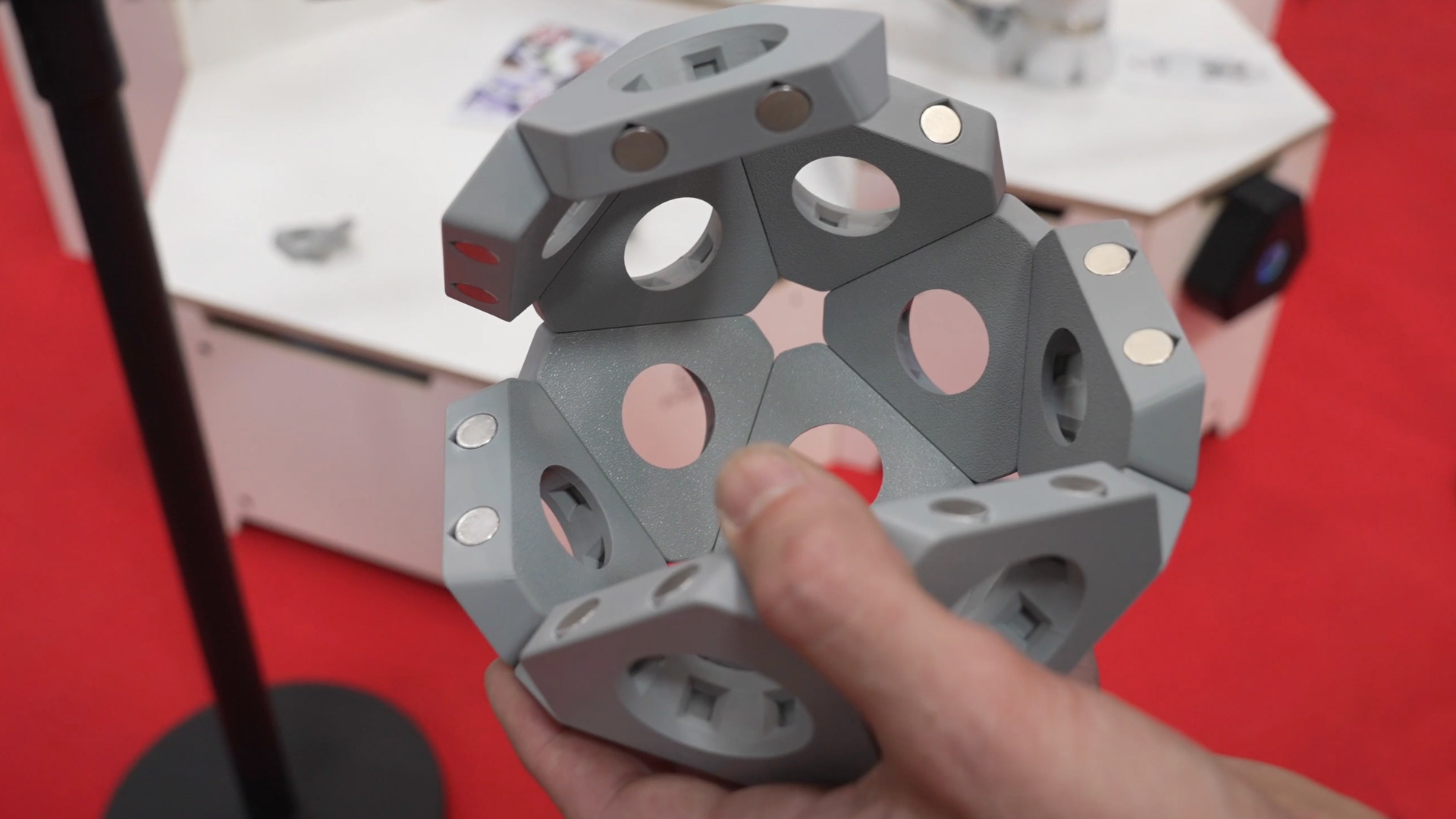

Evasive Robotics is showcasing a special project at the trade fair: robot heads decorated with flowers, known as “EvaHeads,” were created as part of a university project. The aim was to give machines emotions and enable them to interact with people in a new way.

The company is thus demonstrating what its technology makes possible behind the scenes – even though this is not a product, but rather a demonstration of the software's capabilities.

Avoiding collisions: dynamic control instead of rigid safety zones

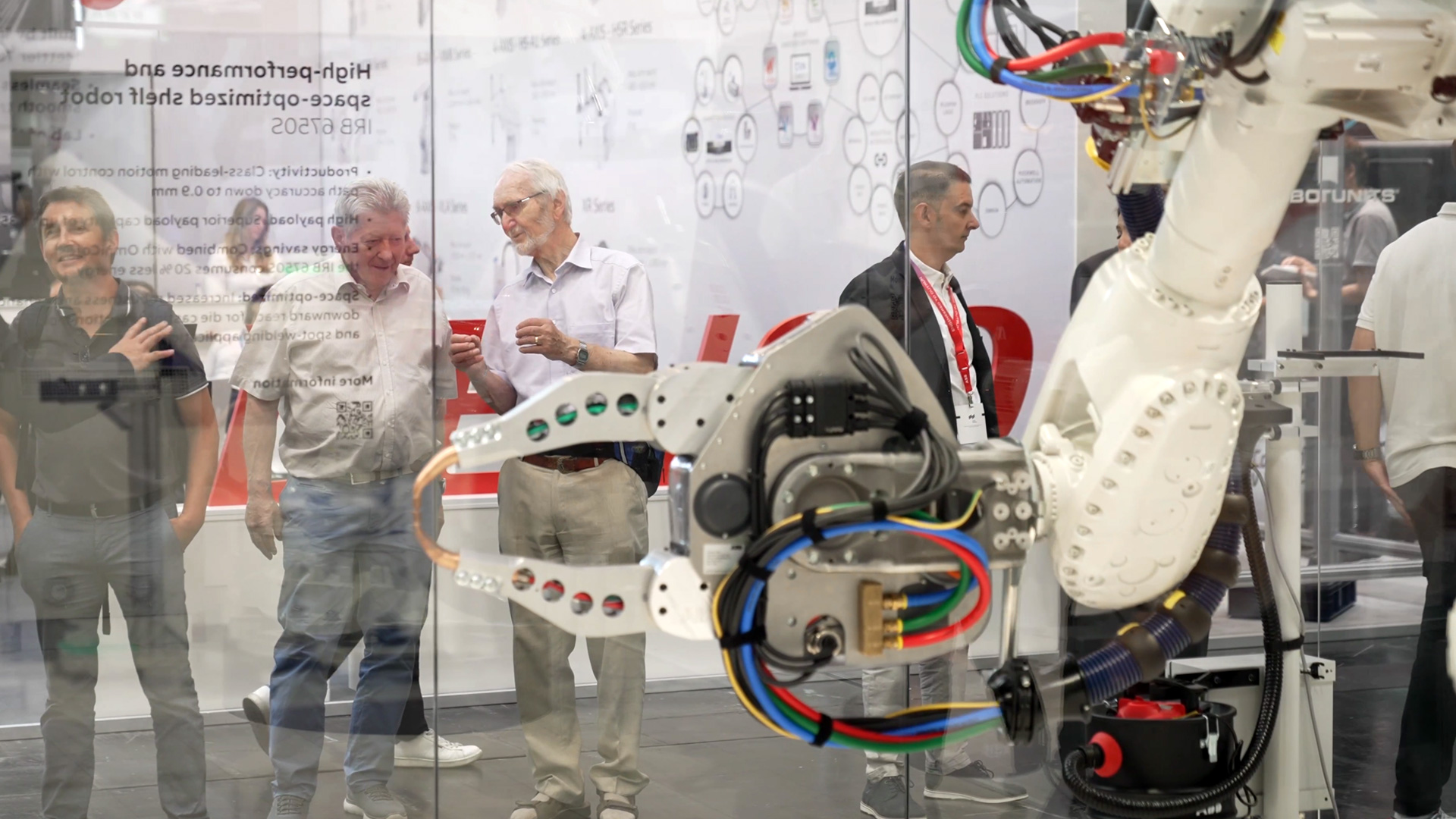

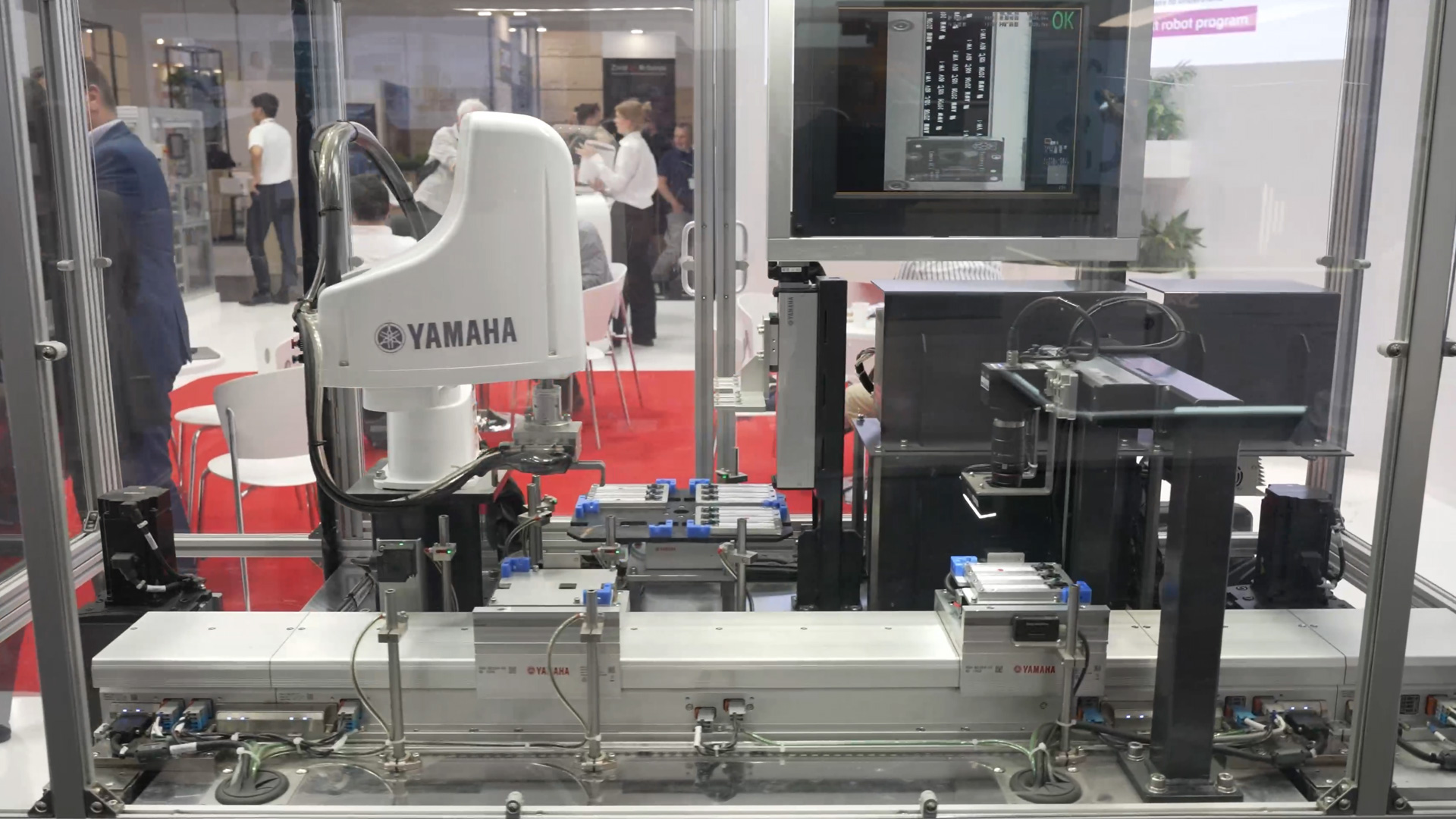

Evasive Robotics takes a fundamentally different approach to traditional industry. Instead of placing robots far apart to prevent collisions, the team focuses on allowing many robots to work simultaneously in a confined space. This is made possible by specially developed algorithms and a completely independent control technology programmed by the company itself – from scratch, without using existing solutions.

The software calculates the positions and shapes of all robots involved in real time, as well as their joint angles and mechanical ranges. This allows different robots – even those from different manufacturers and of different designs – to operate simultaneously on a workpiece or in a workspace without interfering with each other. If they come too close, they automatically move out of the way. This kinematics-independent control system is unique on the market to date.

No fixed movement plans, just flexible state targets

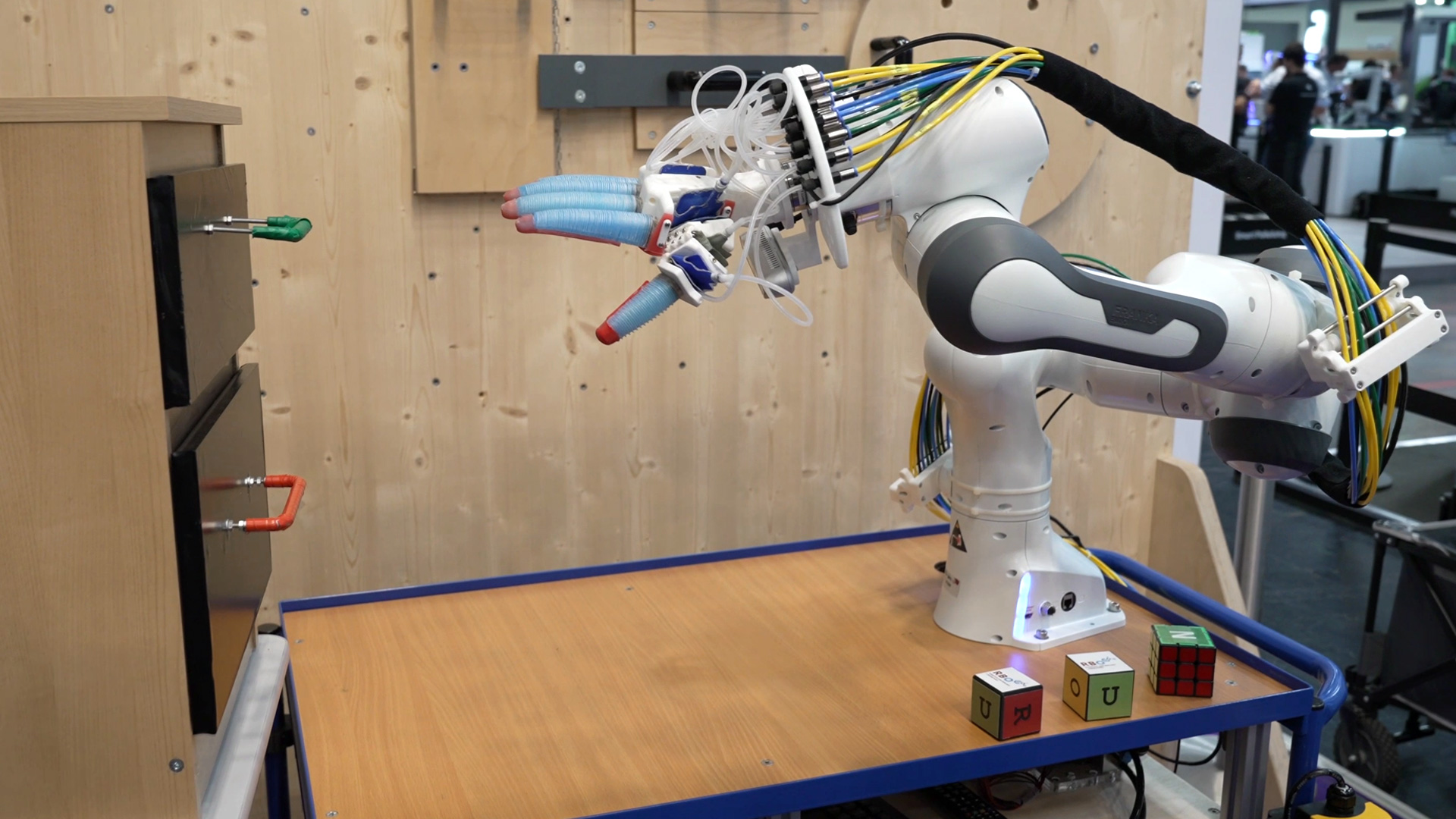

The principle differs significantly from conventional automation: Instead of programming a robot step by step (“Go here, grab there, pull open the drawer”), Evasive Robotics only defines the goal – for example, that the drawer should be opened.

The robot then visually recognizes objects, triangulates the position of the handle, and independently performs the appropriate movements. If the situation changes – for example, because the drawer slips or is pulled away – it notices this immediately and adjusts its action without having to restart a fixed plan.

Even if the robot is disrupted by external influences, it corrects its behavior live: It searches for the drawer again, grabs it, and opens it without this sequence ever having been explicitly programmed. Only the logical dependencies, such as the fact that the drawer must be grabbed before it can be opened, are stored in the system.

New possibilities for the shop floor and industrial planning

This technology also calls the classic manufacturing structure into question. Until now, “state of the art” has meant positioning robots far apart to avoid collisions.

Evasive Robotics is completely rethinking this and says: “Put them closer together, shop floor space is expensive.” The algorithm ensures that even with complex tasks, several robots can work close together without getting in each other's way.

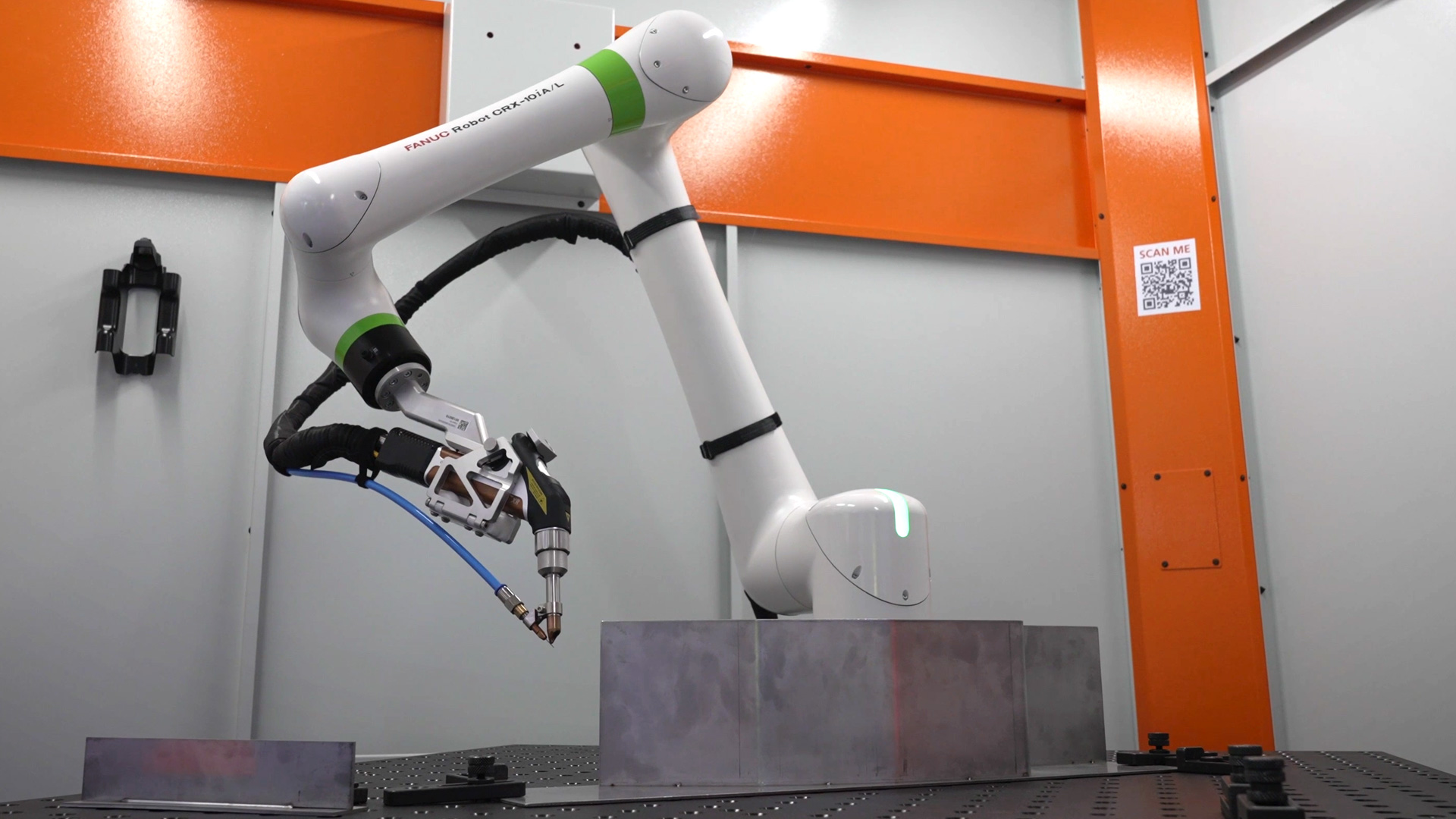

This opens up completely new perspectives for industrial layout planning. Instead of wasting a lot of space for safety distances, the available space can be used more efficiently. This potential is particularly evident in multi-robot bin picking, where several robots simultaneously remove parts from a box, or in measurement technology, where robots measure a car body in parallel. The algorithm independently decides which robot intervenes when and where.

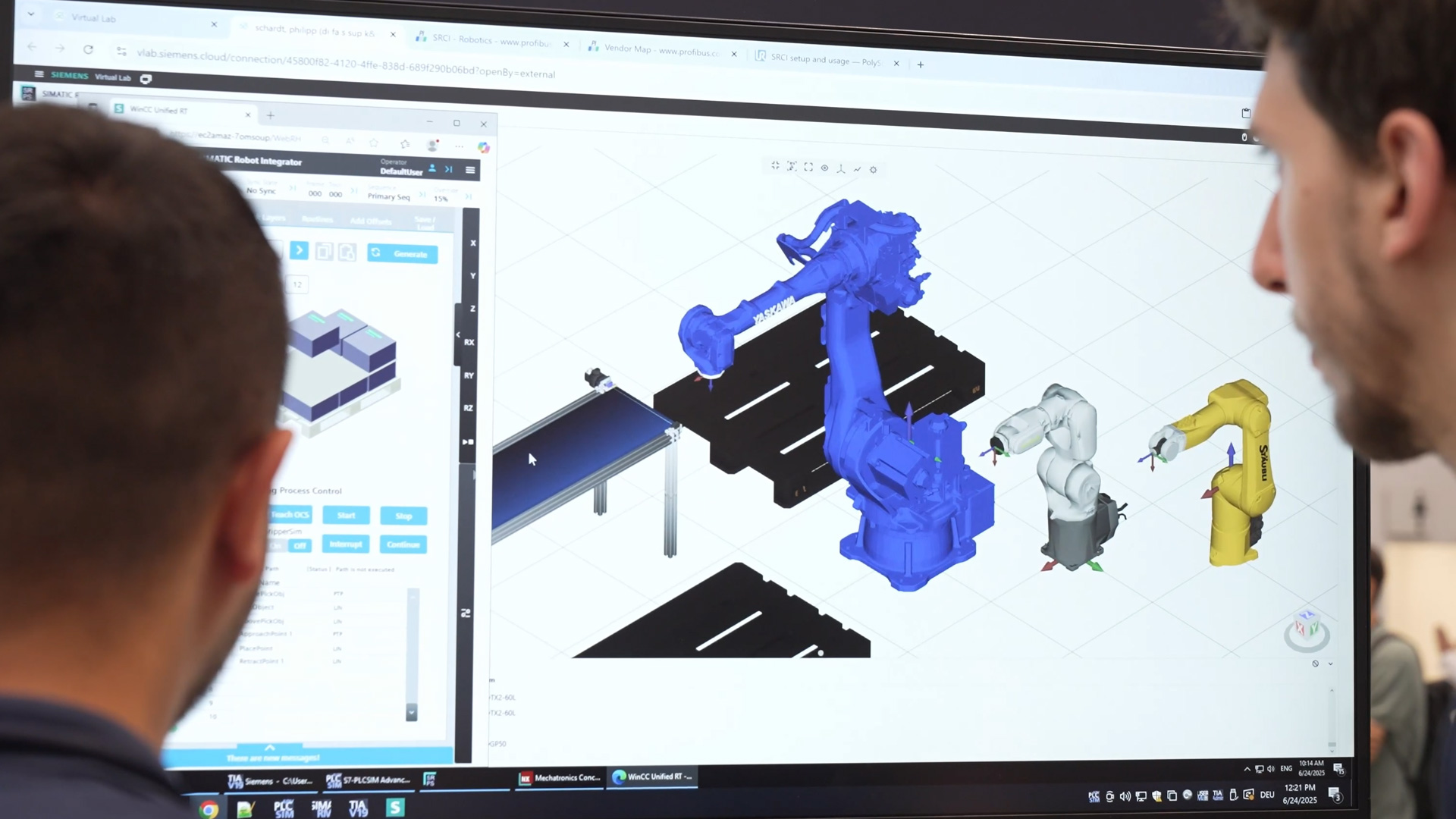

Low computing power, big impact: the hidden key

While other providers solve similar problems using enormous computing power – for example, in supercomputers – Evasive Robotics relies on highly optimized software that requires minimal computing power.

The company is keeping the exact technical implementation under wraps, even referring to a certain “magic.” However, one thing is clear: this efficiency also makes the technology interesting for medium-sized companies, as no complex IT infrastructure is required.

Prospects extending to medical robotics

Evasive Robotics sees applications in a wide range of industries. Possible uses include surgery, similar to the Da Vinci surgical system, where several arms operate simultaneously in a confined space.

The algorithm can also be used in traditional manufacturing, in measurement or assembly processes, to easily integrate new measuring points into the system – the algorithm itself organizes which robot needs to be where and when. This eliminates the need for complex manual engineering work.

The company is convinced that this will solve problems that many in the industry are not even aware of yet – and that the decisive innovation push is only just beginning. The technology breaks with decades-old concepts of automation and promises to fundamentally change the shop floor.