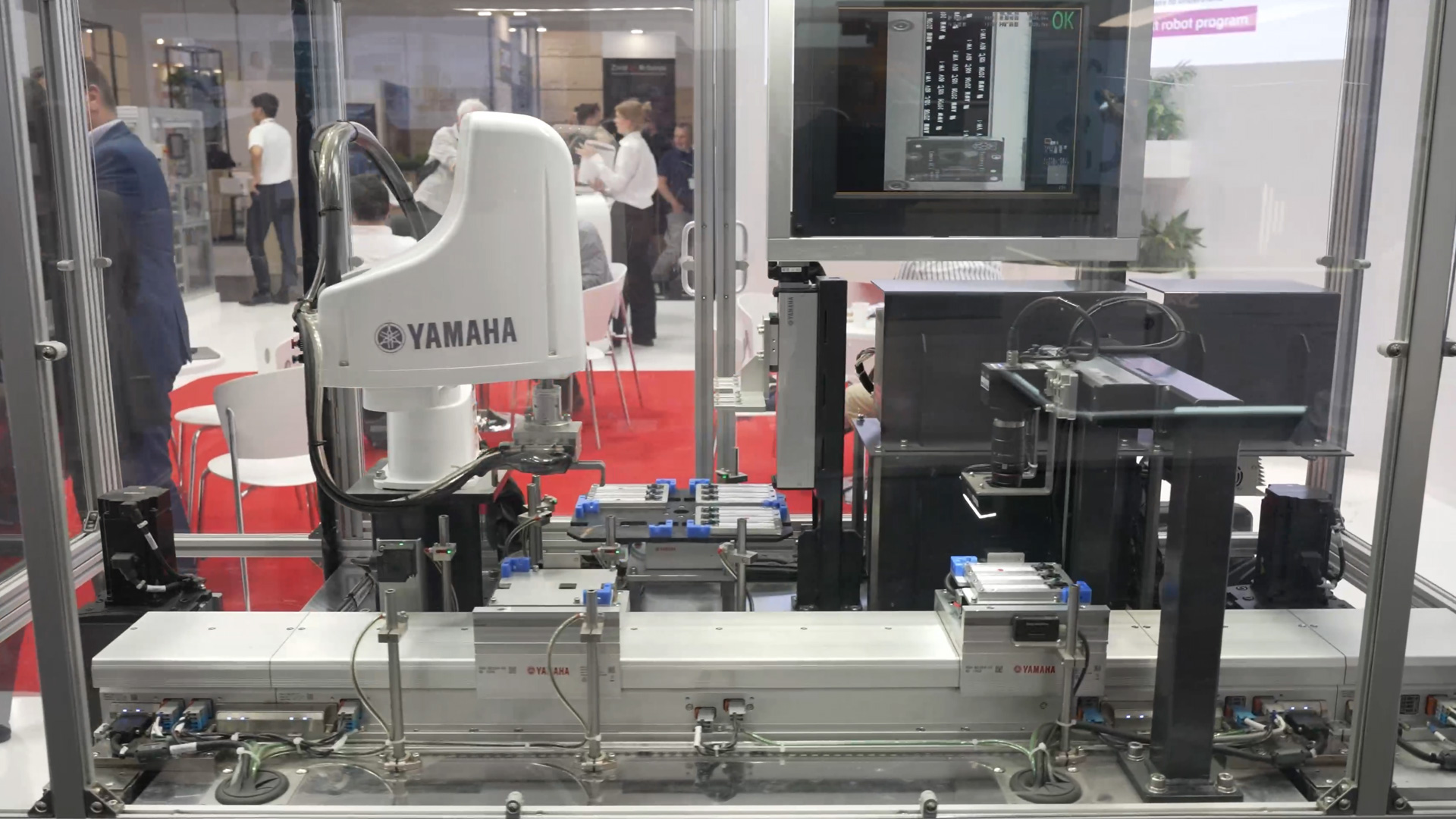

At automatica, Yamaha Robotics will be focusing on a system that combines several tasks at once - in the smallest of spaces. The Linear Conveyor System offers a combination of conveyor technology, robotics and inspection. It demonstrates how high-precision manufacturing and inspection processes can be implemented in a compact and modular way.

The Conveyor System from Yamaha is available in both vertical and horizontal versions. In the application presented here, ribbon cables are checked - first for function and then for correct solder connections using optical inspection.

The modular design allows flexible configuration of the line: test stations, pick-and-place units or assembly tasks can be arranged as required. This makes the system suitable for both production and inspection processes.

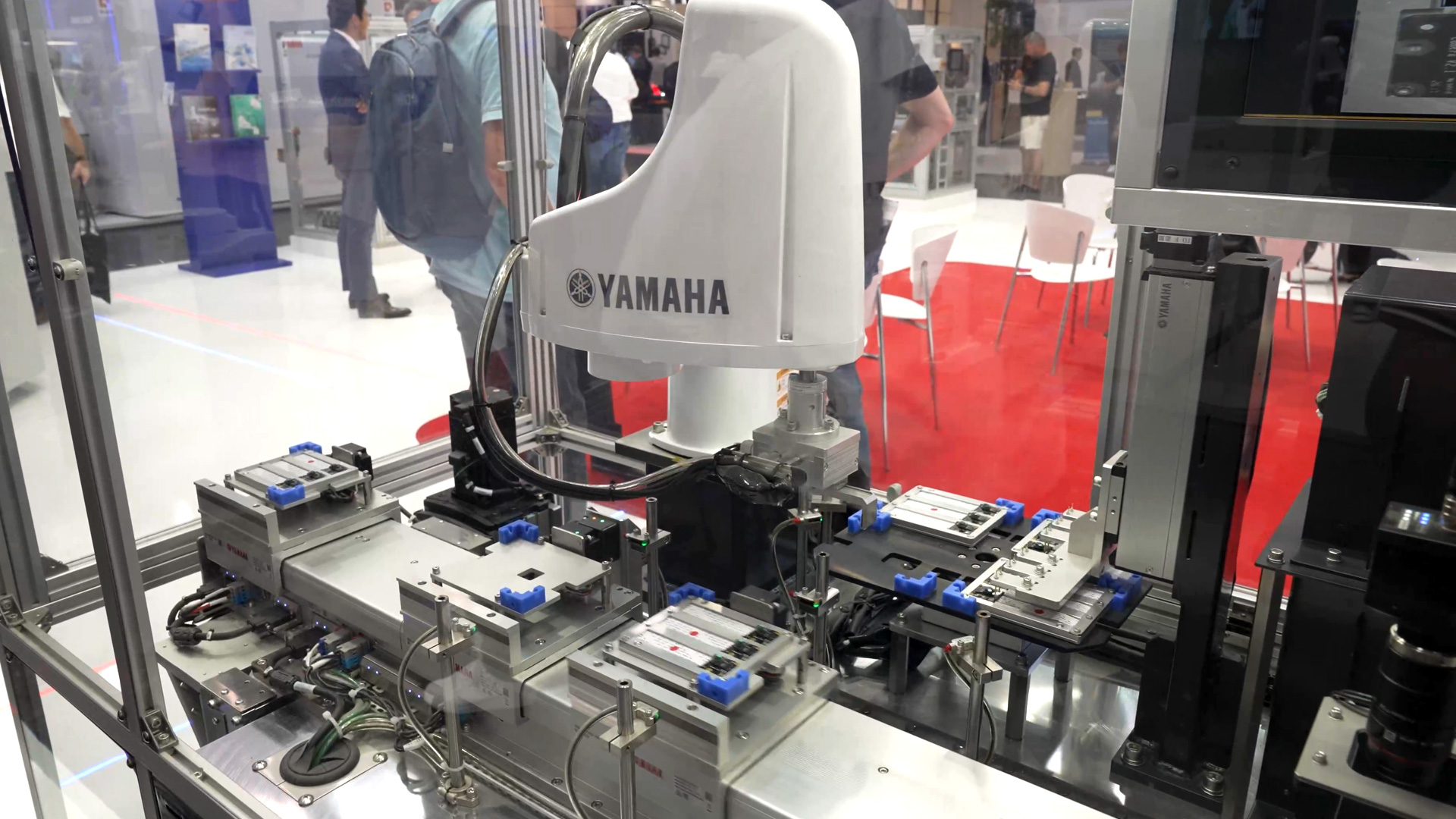

All the main components in the demo system come from Yamaha: the conveyor system itself, the SCARA robot, single-axis axes and the vertically movable traverses. This complete integration enables a coordinated system solution without interface problems - an advantage that is particularly important for compact systems.

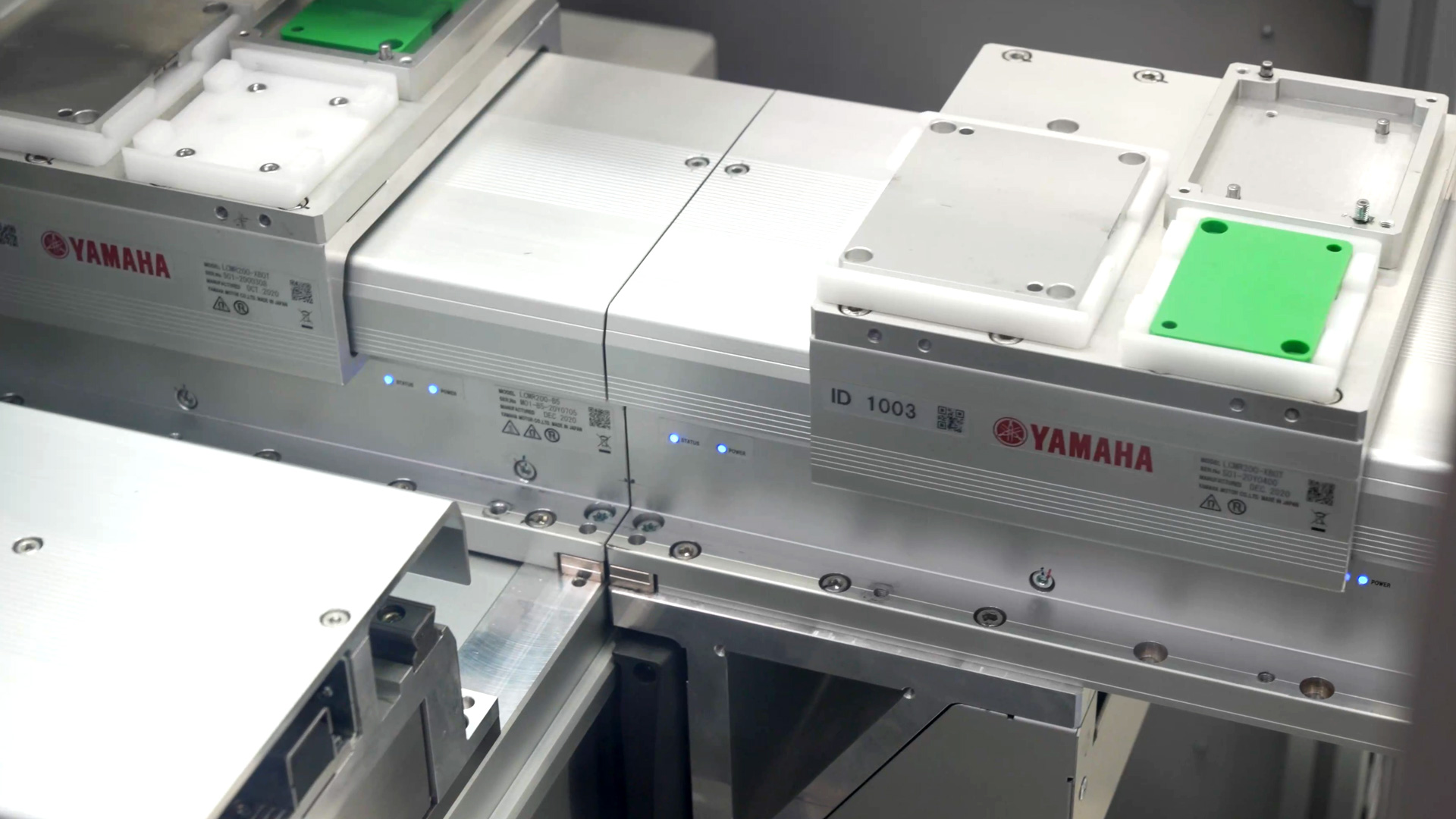

The sliders move magnetically and reach speeds of up to 2,500 mm per second. The repeat accuracy is 5 micrometers. The tolerance inside the slider is around 15 micrometers, which is more than sufficient for many standard applications.

However, if you want to achieve 5 µ throughout, you have to program individual sliders specifically - an effort that is only worthwhile in high-precision applications. In normal operation, the units work in a master-slave network, which allows simple control.

Another part of the system shows an exemplary assembly cell, for example for hard disk assembly. Here, the robots pick up individual components, place lids on them and screw them together. The parts are transported in a circulating manner on the conveyor line.

The cluster can be flexibly adapted - both in terms of length and the arrangement of the modules, depending on the available space and process requirements.

The system allows up to 64 sliders at the same time, although some control modules have to be removed - around 62 are realistically usable. This opens up a wide range of possibilities when designing complex production lines.

The clusters can also be extended or configured at different distances if required. The mechanical axes and drives are designed in such a way that individual adaptations are possible at any time - an important prerequisite for use in customer-specific automation projects.

With this demo line, Yamaha shows that compact automation does not have to come at the expense of flexibility. Especially where space is limited - as is the case in many production halls - the system offers the possibility of combining several processes in a single system.