Nabtesco is considered the world's largest manufacturer of cycloidal gears. Around 60 percent of all industrial robots today use these high-performance components in their axes. The company covers the entire spectrum: shaft gearboxes are mostly used for smaller applications such as cobots or humanoid robots.

These can be manufactured more compactly and are designed for lower torques. Larger industrial robots, on the other hand, rely on cycloidal gears, which can withstand extreme loads and are also characterized by their durability.

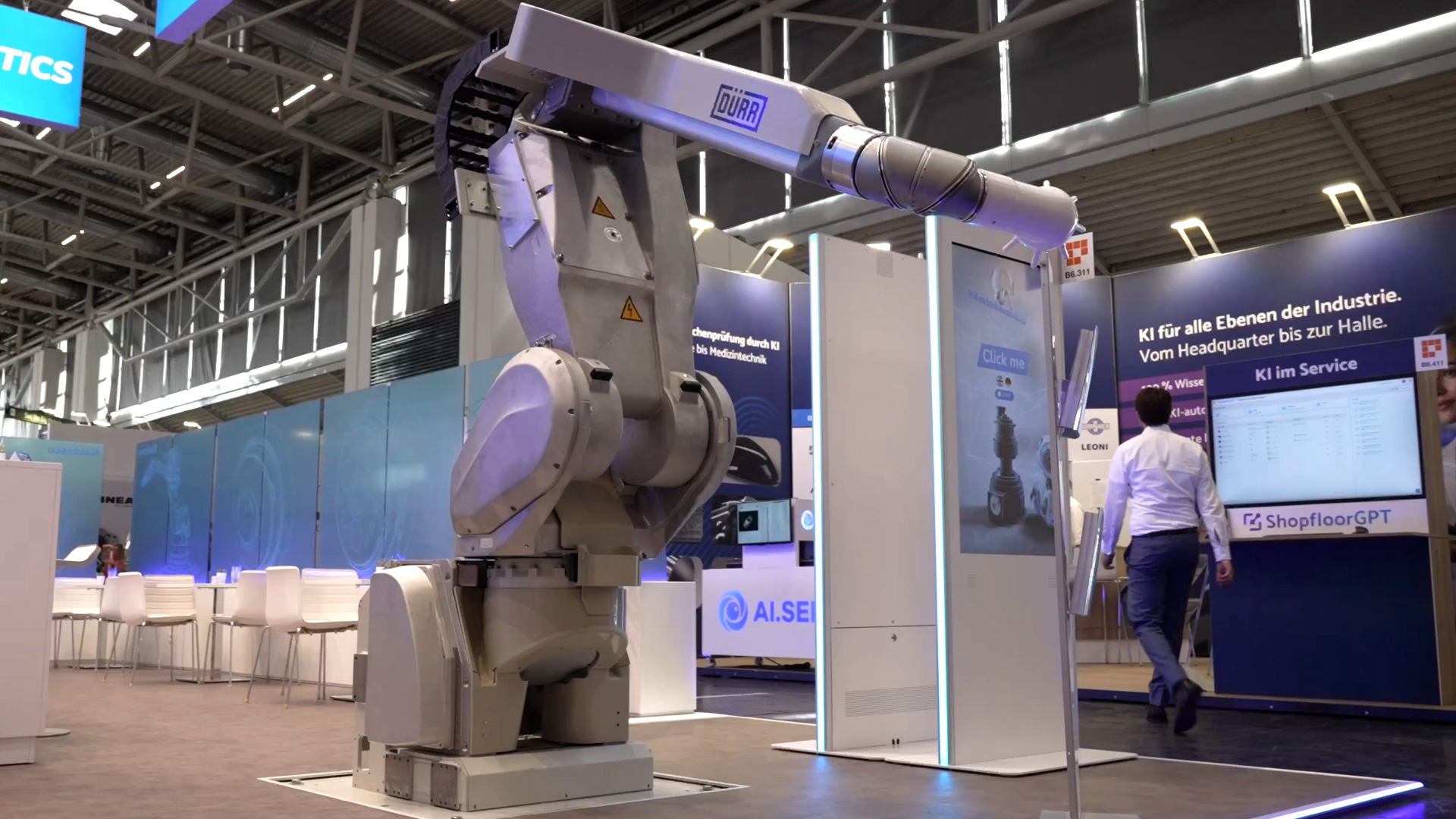

At automatica, Nabtesco used a painting robot to demonstrate how the gears are installed inside a robot. It usually starts with a hollow shaft gear in the base axis, through which cables and lines can be routed. The second axis is often subject to the highest loads and requires a solid shaft gear that reliably transmits high torques.

Nabtesco gears are designed to absorb five times their rated torque without damage. Hollow shaft gears are then used again at the top of the robot joints to create additional space for cables.

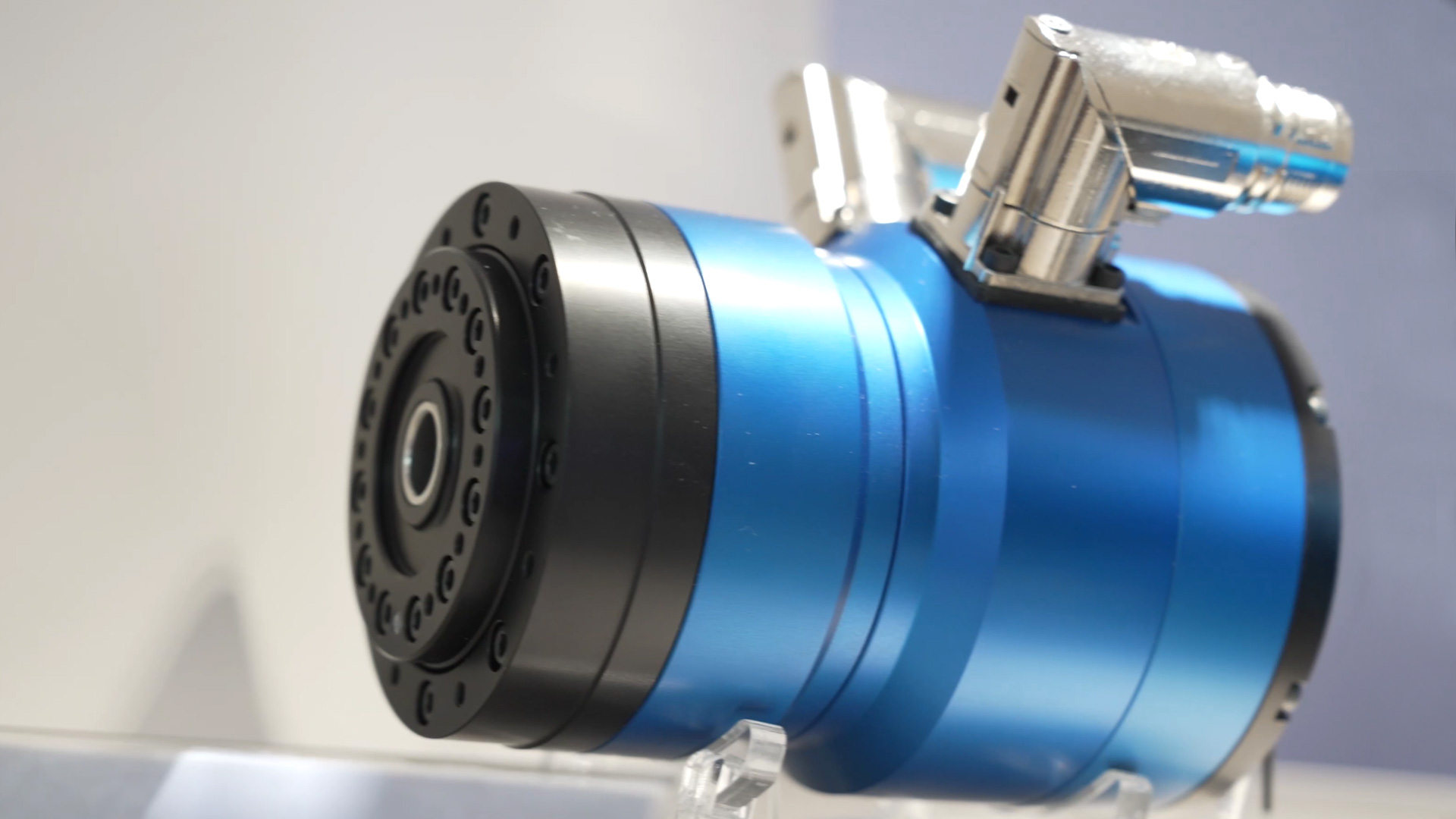

Another highlight at the trade fair stand was the modular actuator concept. These drive units can be individually configured according to customer requirements—for example, with an integrated brake or additional controller. This allows machine builders and robotics manufacturers to design their applications flexibly and in a space-saving manner.

The high power density of the actuators makes them particularly interesting for areas where installation space is limited, such as cobots, exoskeletons, or precision engineering special-purpose machines.

These solutions also play an important role in classic mechanical engineering, wherever high precision is required. The modular design allows specific requirements to be met and the drive to be optimally adapted to the task at hand.

A look at the next stage of development reveals the so-called digital gearbox. Nabtesco integrates sensor technology directly into the gearbox unit without requiring any additional space. This allows parameters such as temperature, load, and remaining service life to be monitored directly.

Such data forms the basis for intelligent evaluations: AI tools can, for example, make recommendations for changing driving profiles in order to achieve a longer service life. They can also predict when a gearbox change is advisable before a failure occurs. These predictive maintenance concepts are designed to help minimize downtime and reduce operating costs.

Nabtesco also showcased an emotional application at automatica: an exoskeleton for paraplegics that brings people who are confined to wheelchairs back up to eye level. The system has six active and four passive degrees of freedom, enabling users to stand up, climb stairs, and walk sideways.

Although such an exoskeleton cannot yet replace a wheelchair, it helps to activate the muscular and skeletal systems, promote bone density, and strengthen the cardiovascular system. It also gives those affected the feeling of walking independently again—an important contribution to social participation.