At automatica 2025, Siemens is focusing on the requirements of mechanical engineering - with an end-to-end approach that extends from the initial design decision to virtual commissioning. The aim is to support machine builders in making complex automation clearer, more robust and significantly more efficient.

Right at the start of a project, machine builders are faced with fundamental decisions: Which robots should be used? Which control system is suitable? And how can the entire motion technology be sensibly integrated?

Siemens offers tools that start at precisely this early stage and enable end-to-end selection and planning. At the heart of this is the company's own engineering framework - the TIA Portal - which brings all components together on a common platform.

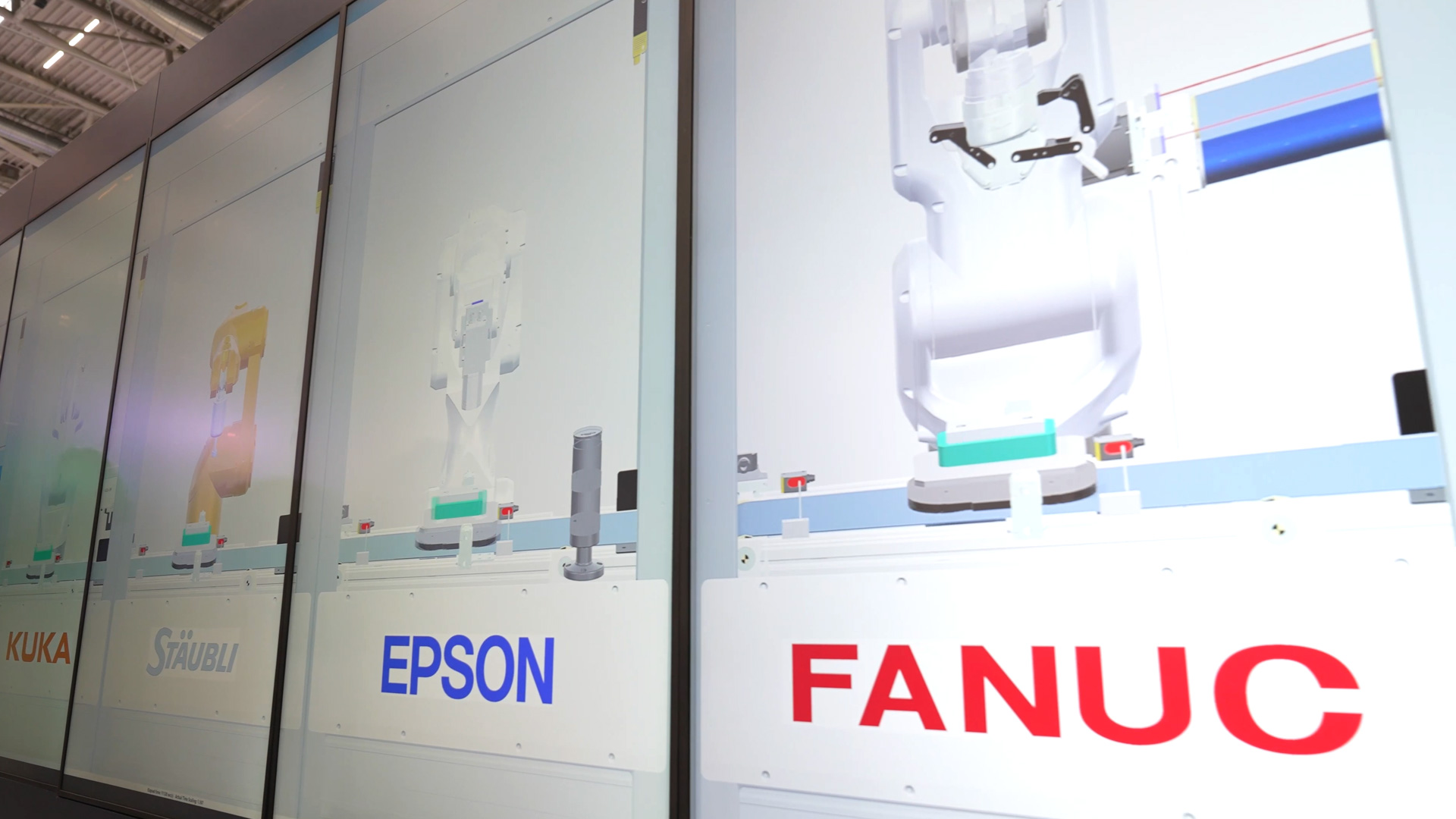

In practice, many manufacturers rely on their own control systems, operating devices and engineering environments. Those who use different robot manufacturers are often faced with a whole collection of different systems - a real burden for maintenance and personnel.

Small and medium-sized companies in particular cannot maintain their own specialists for each platform. Siemens is countering this fragmentation with an open standard that works across all manufacturers.

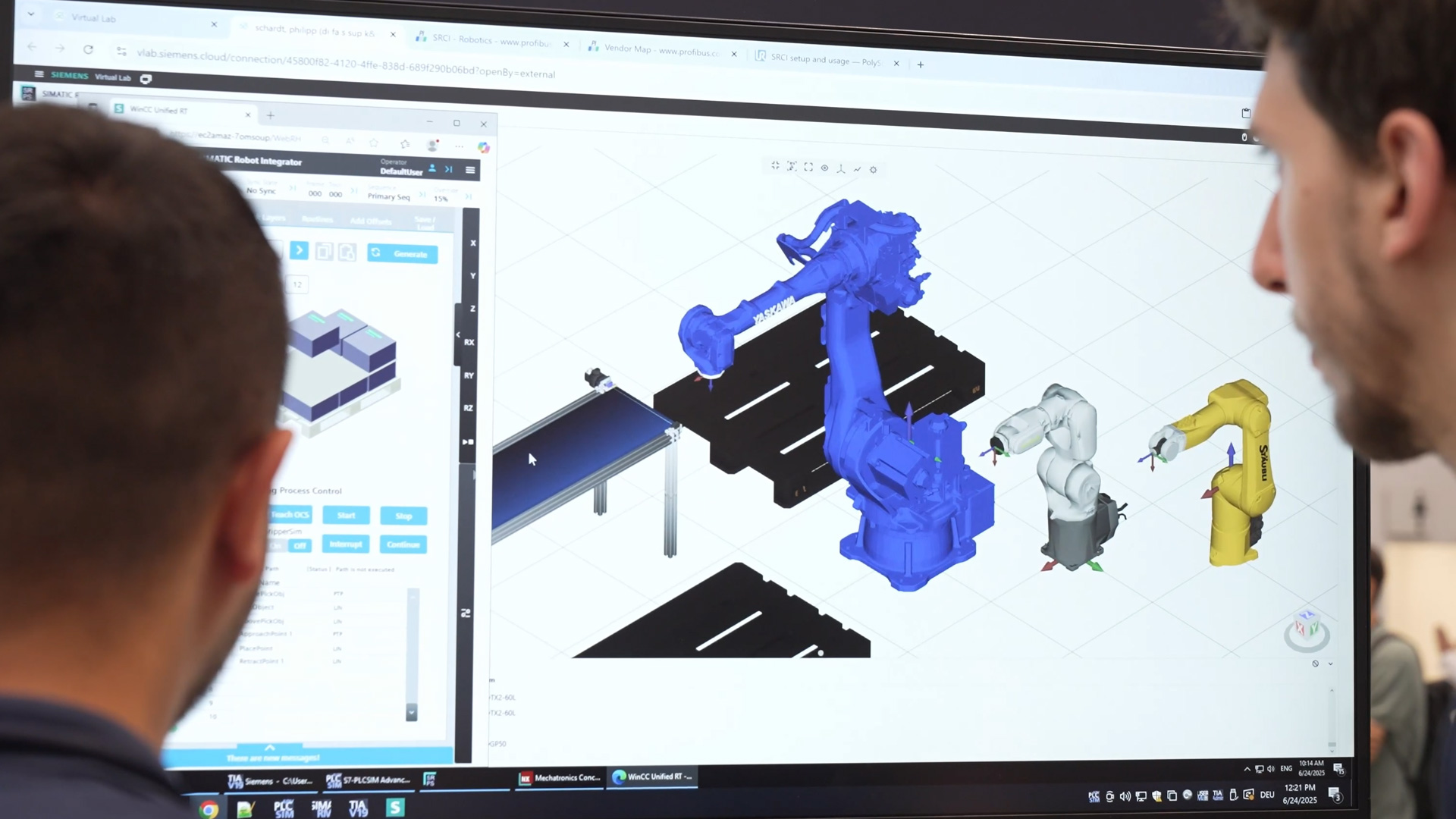

The key lies in the Standard Robot Command Interface (SRCI) - an open interface that does not originate from Siemens itself, but is deliberately open to all market participants. This means that the robots are no longer programmed in their own environments, but directly from the Siemens world - specifically via the Simatic controller in the TIA Portal.

This not only makes robotics integration more standardized, but above all reduces the need to work with third-party tools. For the machine manufacturer, this means the same way of working, regardless of whether the robot comes from ABB, KUKA, Yaskawa or others.

This approach makes engineering independent of the choice of brand. Anyone who develops their own machine standard can set it up flexibly depending on the project - the decision for the robot manufacturer thus becomes a downstream option.

Whether a “blue”, ‘white’ or “orange” robot: the basic concept remains identical. For SMEs in particular, this flexibility is a real step forward - because it reduces dependencies and creates technical and economic freedom.

One point that is crucial in almost every project is commissioning. This is usually the moment when things get hectic - because errors that were overlooked during design or engineering suddenly become apparent.

At this late stage, corrections not only cost time and money, but can also damage machines or pose safety risks for operators. Siemens relies on simulation as a central component of the development process.

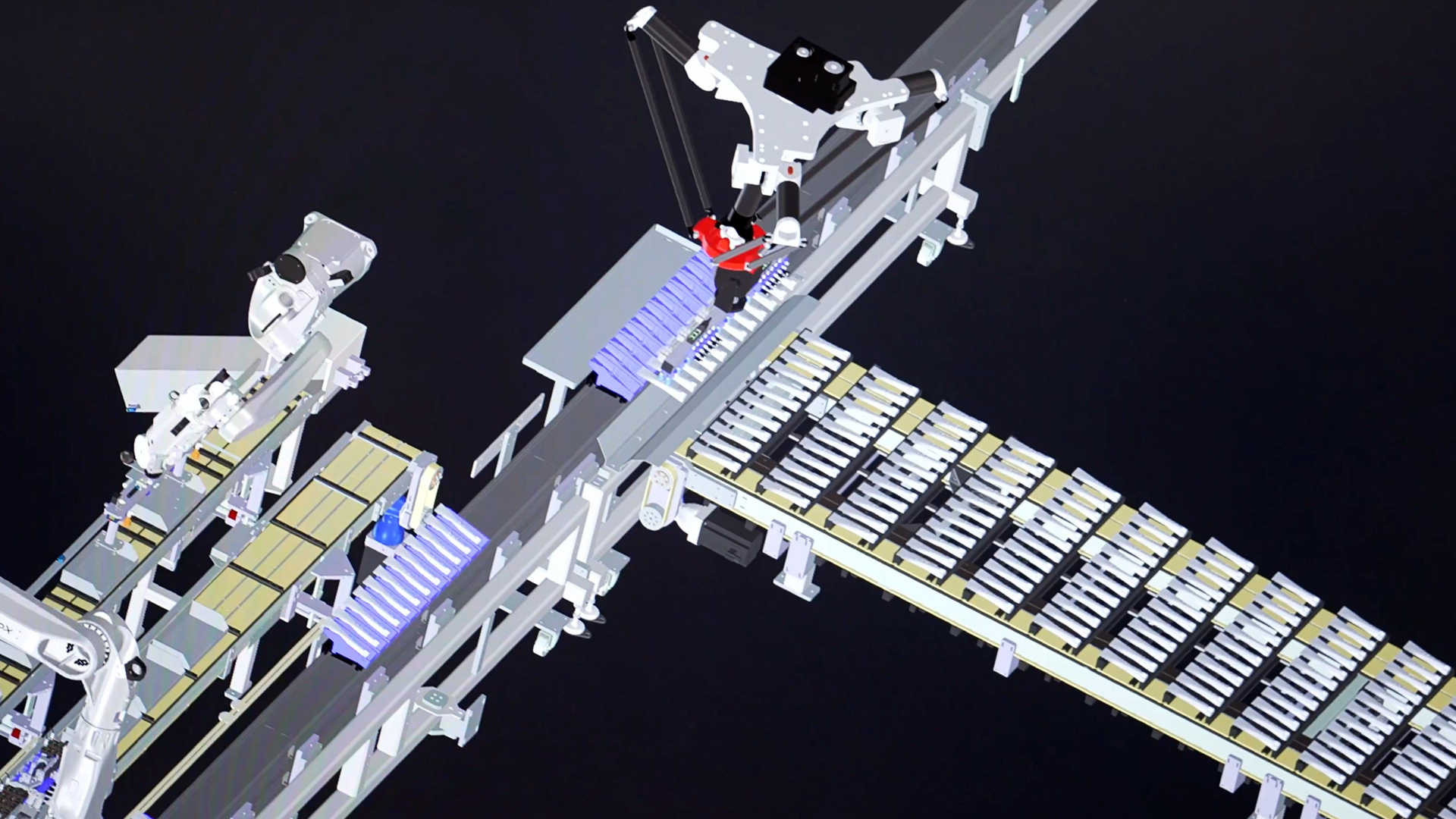

With the Mechatronics Concept Designer, machines can be virtually mapped and “brought to life” as early as the planning stage. This means that motion sequences, gripper movements and material flows can all be simulated and checked before construction. This not only ensures functionality, but also shows the customer at an early stage how the machine will work later on. What runs on the screen is based on real data - and that creates trust.

This simulation is more than just an animated 3D model. It can be used purely for design validation - or, in combination with a virtual controller, it can become a real virtual commissioning. The logic: what runs virtually without errors can later be transferred almost seamlessly to the real machine. The software is loaded, minor adjustments are made - and production can begin. This saves time, reduces risks and takes the pressure off everyone involved.

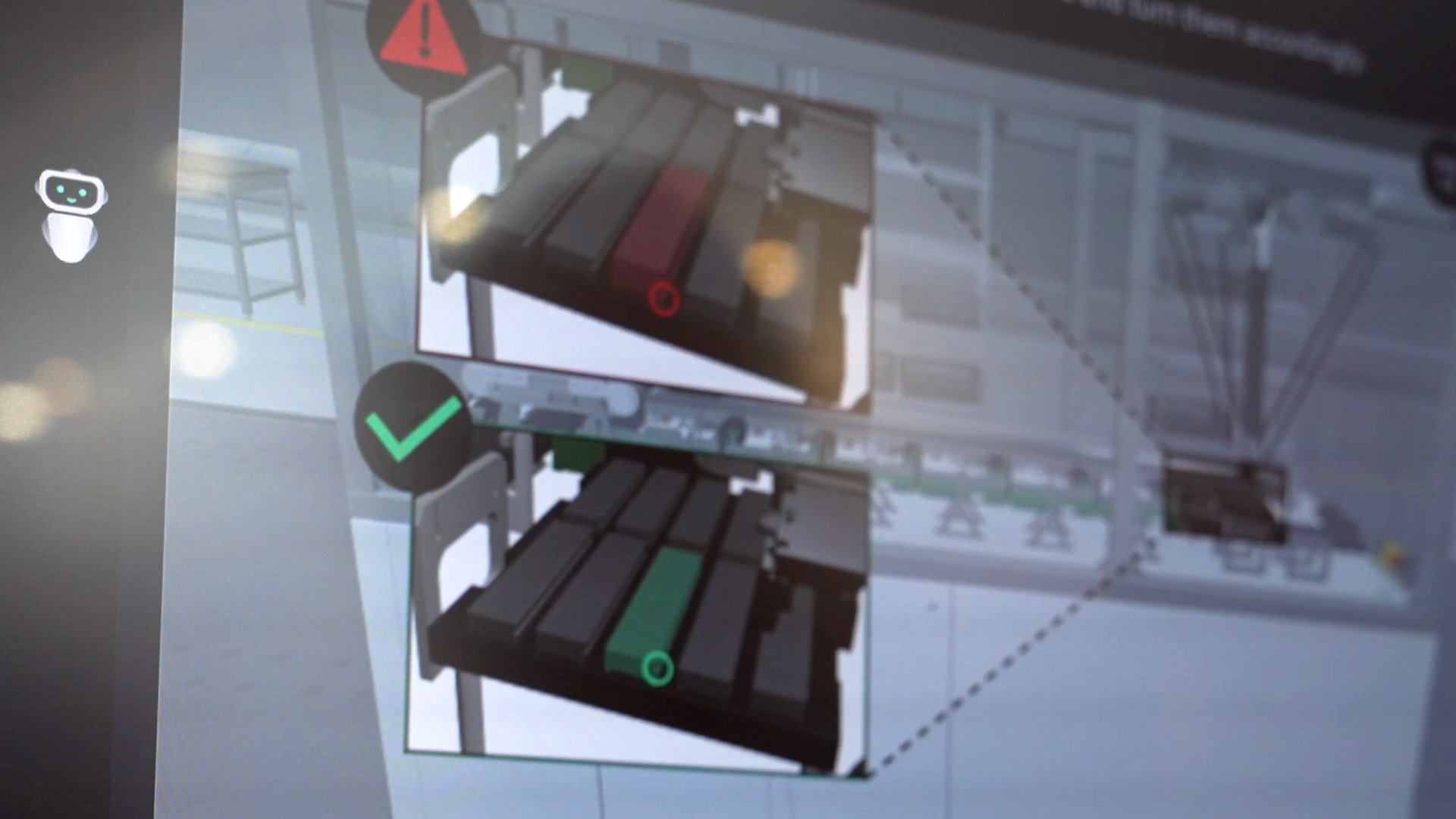

But Siemens is thinking beyond commissioning. How can ongoing operation become safer, more efficient and perhaps even more intelligent? This is where the concept of an AI-supported co-pilot for operations comes in. It is not yet a finished product - but it is a clear vision: assistance software that supports machine operators in their day-to-day work.

For example, when troubleshooting, interpreting fault messages, documenting or answering operating questions. The idea: instead of poring over manuals or asking colleagues, the co-pilot should provide targeted assistance - directly in the user interface or via accompanying systems.

This co-pilot concept is part of the Future Automation area, in which Siemens deliberately thinks beyond the boundaries of today. Here, ideas are not simply presented, but invited for discussion. Is this relevant for customers? Which use cases would make sense? What still needs to happen before something like this is ready for production? Siemens uses this space to develop real future scenarios together with customers - practical, not speculative.

At the same time, Siemens offers structured training courses via the company's own Sitrain Center. The training courses cover a wide range of product areas - from maintenance to engineering - and ensure that the technical possibilities of the systems can also be used safely and efficiently in everyday life.