Seco Sensor develops precise ultrasonic transducers for measurement in gaseous media and is continuously expanding the range of applications to include liquids and solids. Areas of application range from medical technology to industrial process control – always with a focus on precise signal quality and stable measurement results.

Seco Sensor specializes in the development and manufacture of ultrasonic transducers that are primarily designed for applications with gaseous media. These sensor components are used in medical technology, for example, to monitor respiratory gas flow or to determine the respiratory rate of patients.

The transducers provide reliable data, particularly when checking whether breathing is taking place and how intense it is. In addition, ultrasonic spirometry is used to determine lung volume, for example to assess performance or for the early detection of health impairments.

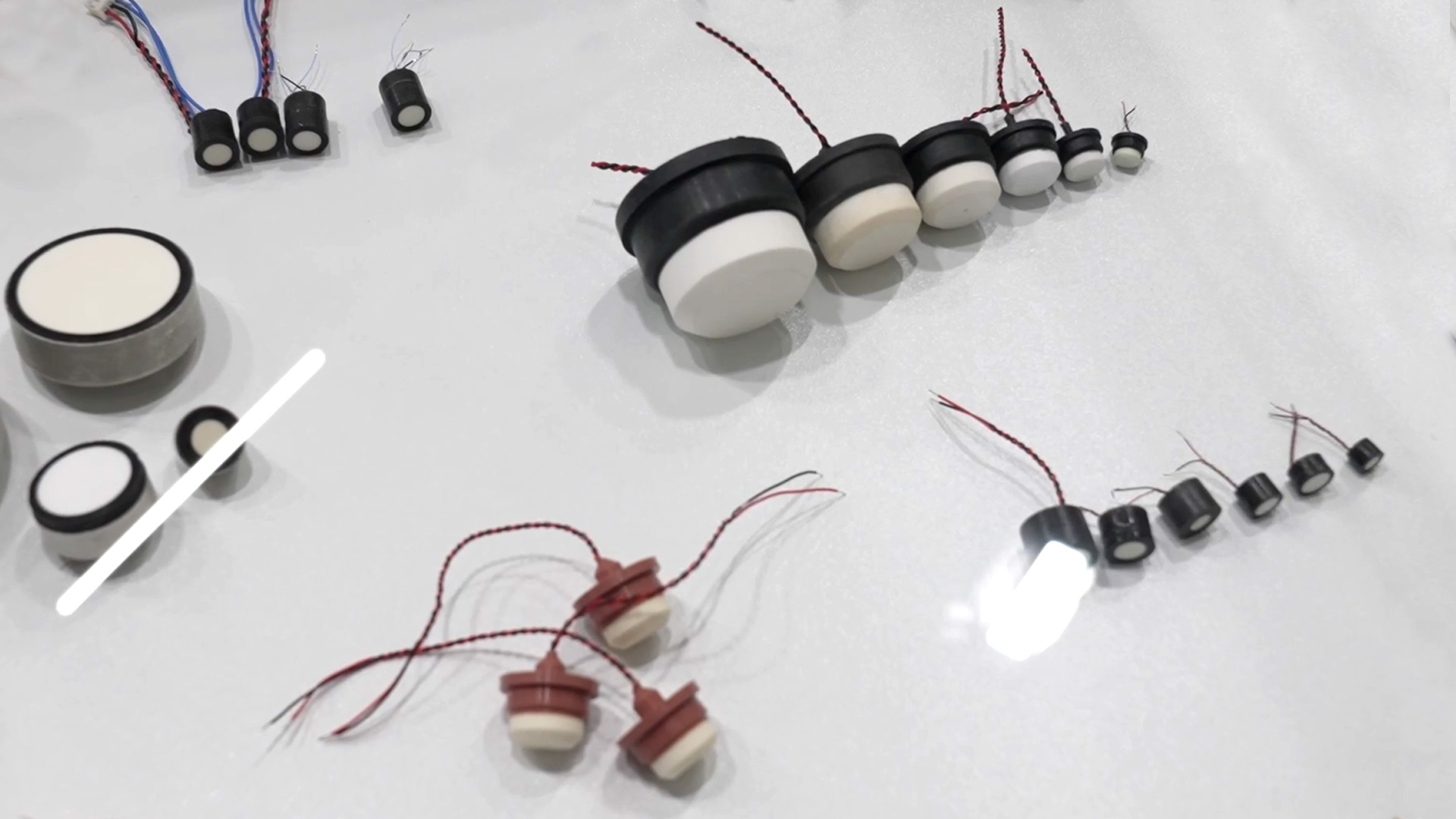

Although the focus has been on gaseous media to date, Seco Sensor is increasingly expanding the range of applications for its transducers to include liquids and solids. Manufacturing requires careful coordination of all material components.

At the heart of the device is a piezo ceramic embedded in a white adaptation material for air transmission. Only when all surrounding materials are optimally coordinated can a clearly defined and consistent signal be guaranteed – a prerequisite for reliable evaluation in a wide range of applications.

In addition to medical applications, Seco Sensor will also be showcasing various industrial solutions at the trade fair. One example is the use of fork barriers for label counting or web edge control in the printing process. Multiple array fork systems enable edges to be detected and adjusted with precision – an important prerequisite for consistent print images and exact positioning of materials. The combination of robust design, high signal quality, and flexible transducer arrangement opens up numerous automation possibilities in industry.

The use of ultrasonic transducers in anemometry – i.e., the measurement of wind speed and direction – deserves special attention. Four transducers are used in special measuring cells as two transmitter-receiver pairs. These enable precise real-time measurements in wind turbines or meteorological systems.

A unique feature of Seco Sensor transducers is their wide opening angle. This allows reliable measurements to be taken even at very high wind speeds, whereas competing products of a similar size usually have narrower sound beams and therefore a shorter measuring range.

The precisely coordinated design is crucial to the performance of the transducers. The signal is generated not only by the piezo ceramic, but also by the exact selection and combination of materials surrounding the sensor element.

The white matching material optimizes the coupling to air, resulting in a clearly defined signal that is reproducible and evaluable. Continuous quality control of the design ensures consistent results – regardless of the application or environment. Seco Sensor thus meets high requirements in medicine, industry, and environmental technology alike.