A young company from Würzburg is launching a novel technology that detects pathogenic bacteria significantly faster than conventional laboratory methods. The solution was developed from university research and is aimed particularly at the food industry.

The company was founded in 2021 as a spin-off from the University of Würzburg and has its roots in a basic research team. Behind the project are Dr. Henriette Maaß, Enno Schatz, and another co-founder. For four years, the trio has been working on a platform technology that was originally designed for the analysis of micro- and nanoplastics. Today, it enables the detection of a wide variety of contaminants – from plastic particles to pathogenic germs.

The technology is currently in the final development phase and is already being used in pilot projects with partners from the food industry. Food analysis laboratories and meat processors are particularly interested. The aim is to achieve market readiness at the beginning of next year. The versatility of the method is considered its key strength: the platform can be flexibly expanded with additional bacterial strains or substances such as PFAS.

Initial proof of the system's functionality has been provided in minced meat. If bacteria can be successfully identified there, this opens up potential for other complex samples, such as drinking water, blood, or urine. The method therefore promises not only time savings but also a significant expansion of existing diagnostic options. The approach has since been recognized with a nomination for an innovation award—an honor that came as a surprise even to Nanostruct.

At the heart of the development is a process in which a laser irradiates the sample. The molecules it contains – especially bacteria – begin to vibrate in a characteristic manner. These movement patterns are specific to each pathogen and can be detected optically. The challenge here is that such signals are weak and often noisy. This is where specially developed nano-based amplifier sensors come into play, amplifying the signal billions of times – until individual bacteria can be detected.

Compared to classic laboratory diagnostics, which often rely on PCR methods with an incubation time of at least 24 hours, the new system delivers results within a few minutes. This means that samples that appear unremarkable on the surface but already contain dangerous germs can also be analyzed. The advantage is particularly evident in the detection of listeria: the method detects lower levels of bacteria earlier and enables rapid intervention before products reach the market.

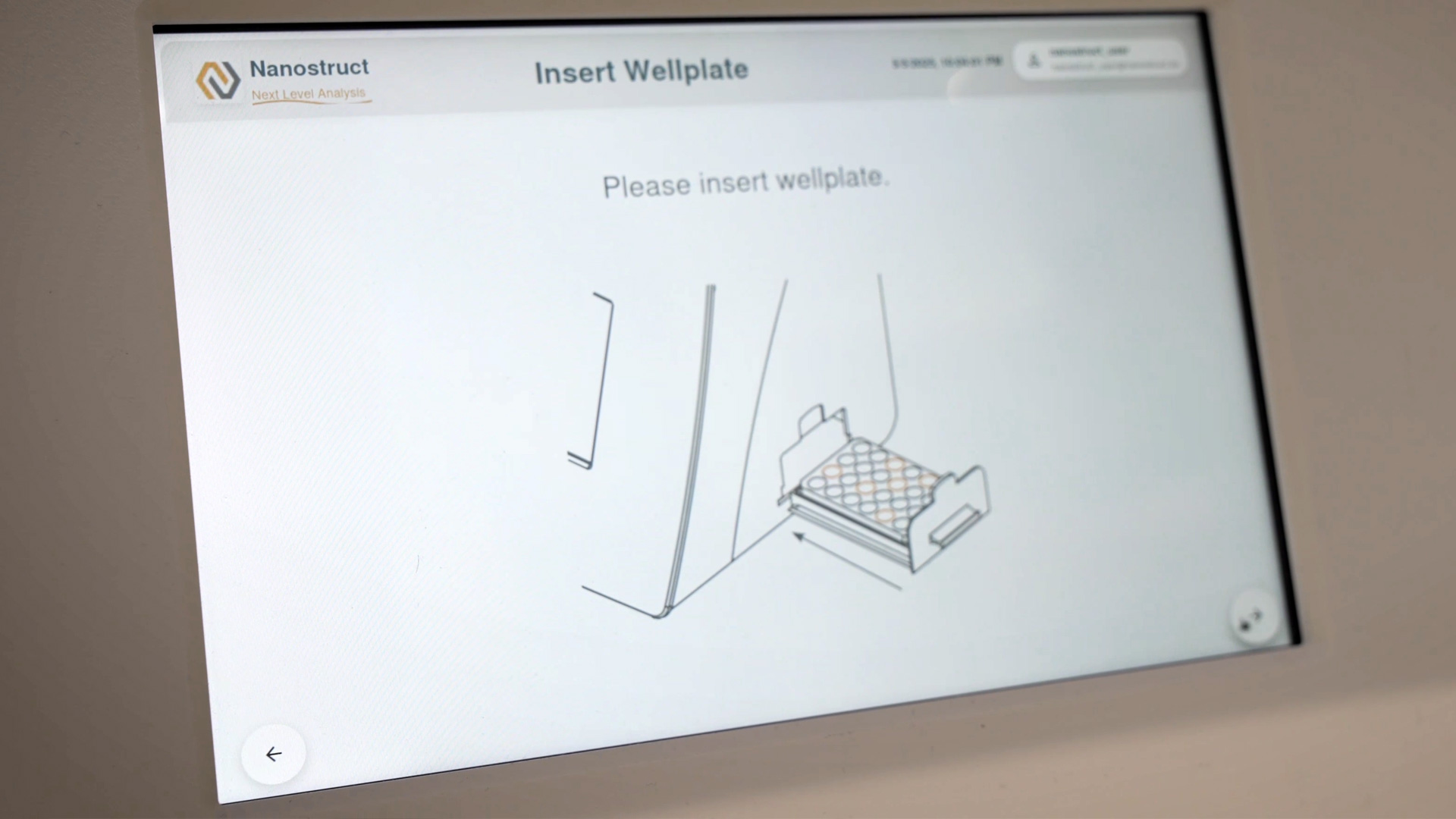

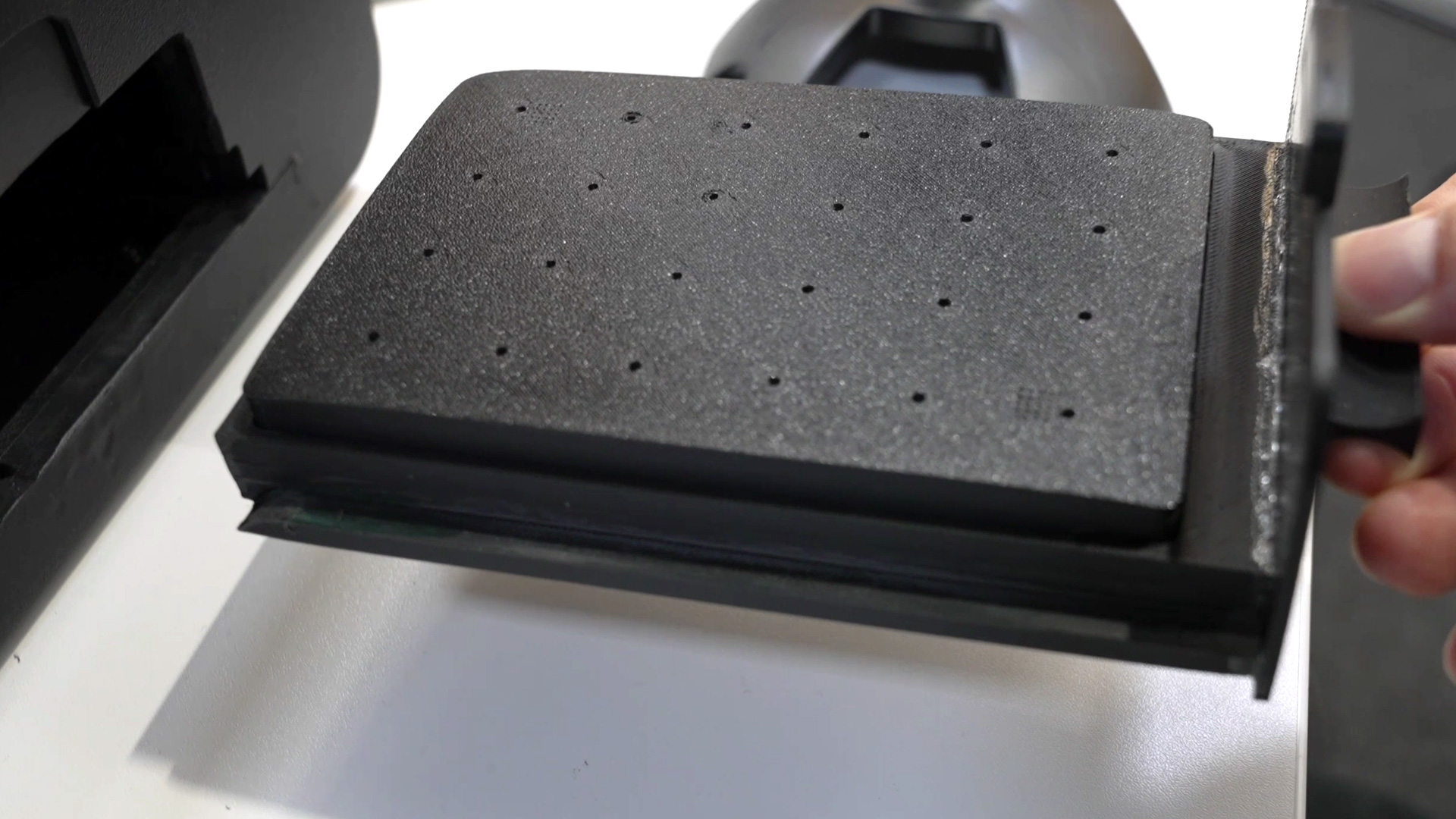

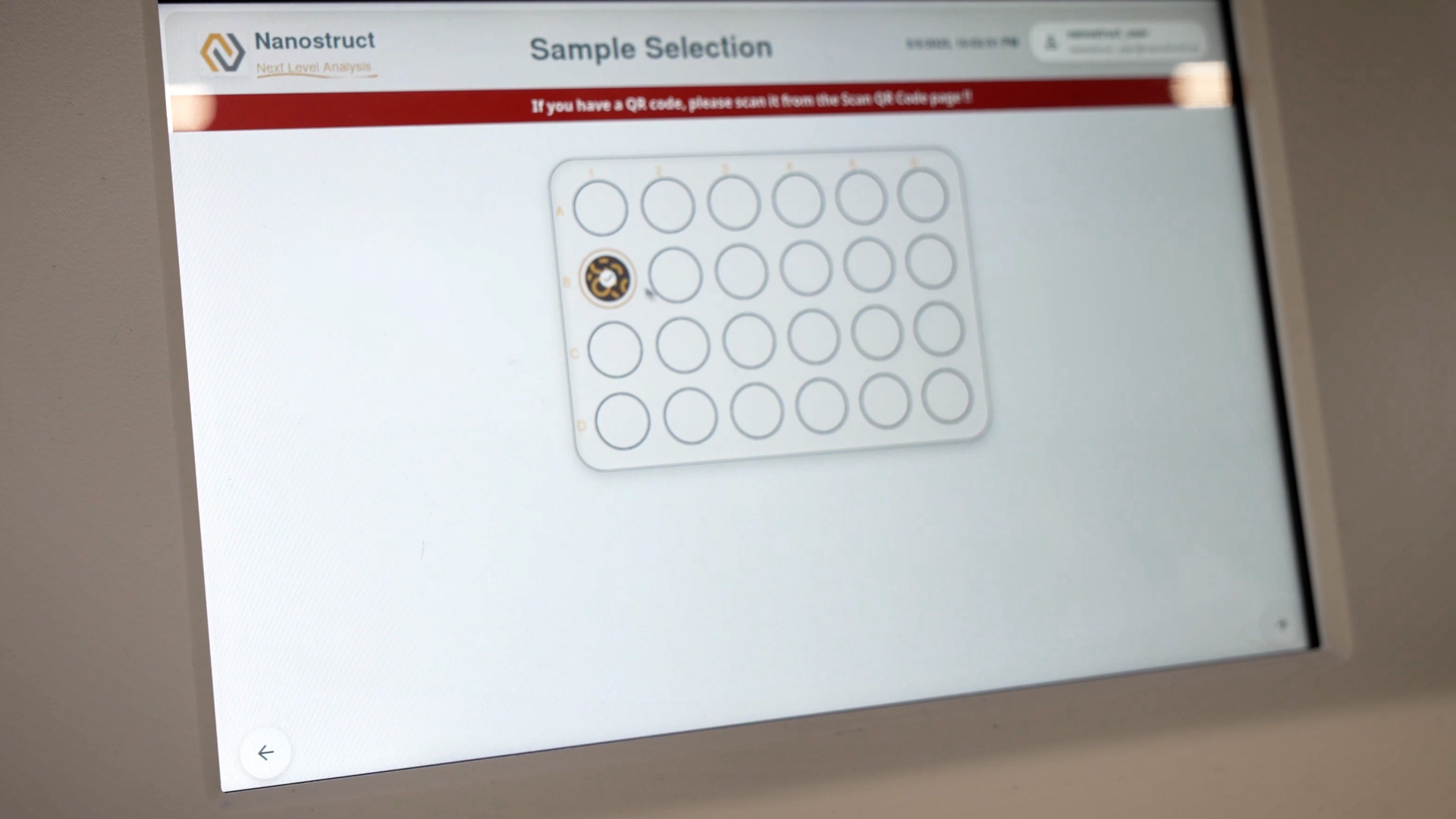

The samples are placed on standardized well plates and scanned by a spectrometer using a laser. The results appear in software that signals red or green to indicate whether contamination is present. Individual measurement points can be selected and checked. The system is designed so that the process can be seamlessly integrated into existing laboratory processes without extensive training or changes.

The platform technology from Würzburg provides an innovative answer to the challenges of microbial food safety. Thanks to its high sensitivity, short analysis times, and flexible expandability, it could establish itself as a new tool for industry and laboratories—with prospects far beyond the food industry.