With intelligent sensor solutions for industrial applications, Endress+Hauser targets manufacturers of measuring systems who rely on customized components beyond standard products. The focus is on ceramic pressure sensors with exceptional overload resistance, compact radar modules for precise level measurement, and a high-temperature-resistant ultrasonic measuring system that does not require decoupled mounting.

Ein wesentliches Element der präsentierten Sensorik ist der sogenannte Ceracore 4.0 – eine Druckmesszelle, deren zentrales Bauteil aus hochreiner Keramik besteht. Der verwendete Werkstoff auf Basis von 99,9 % Aluminiumoxid zeichnet sich durch seine Beständigkeit gegenüber abrasiven wie auch korrosiven Medien aus.

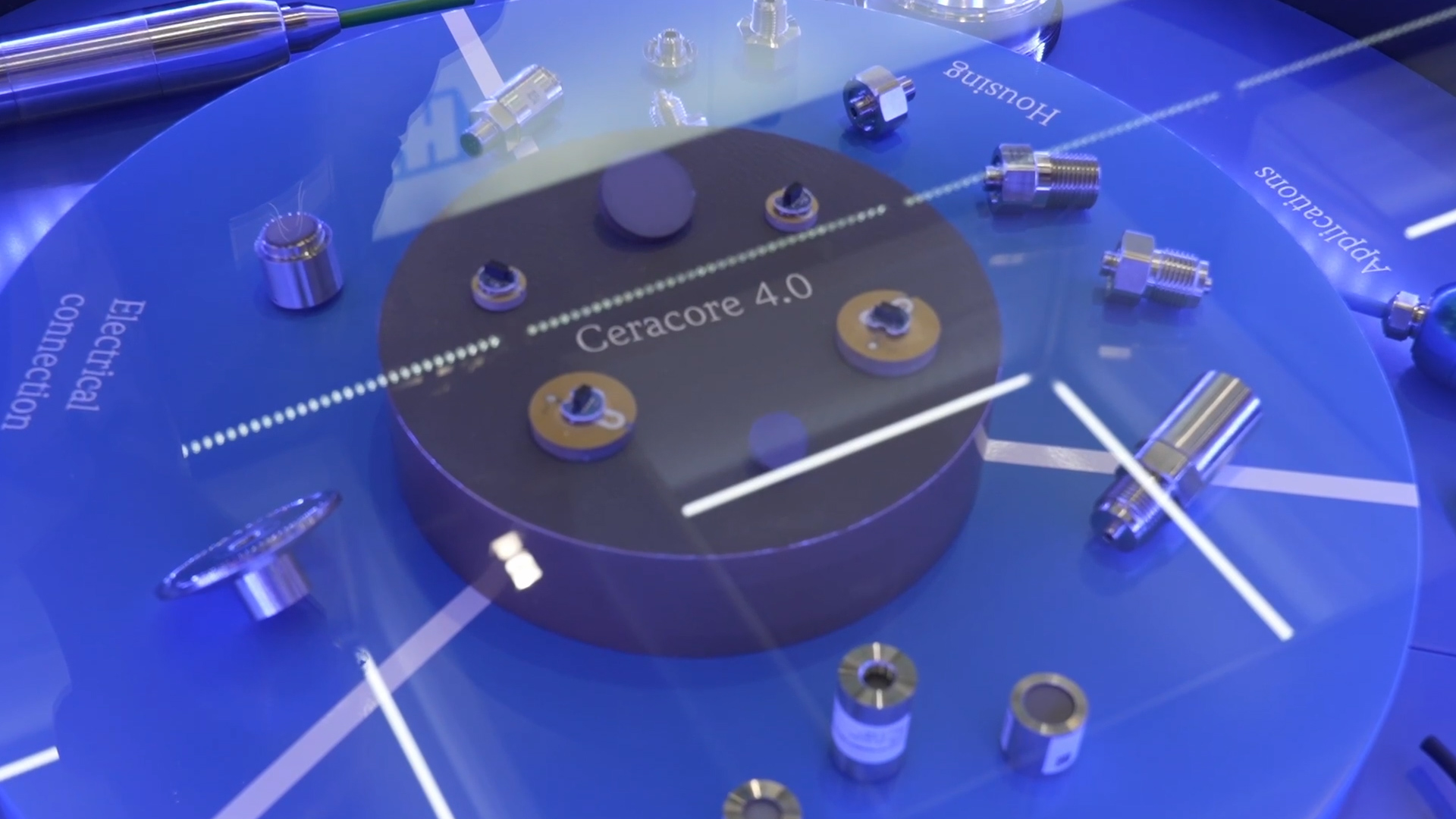

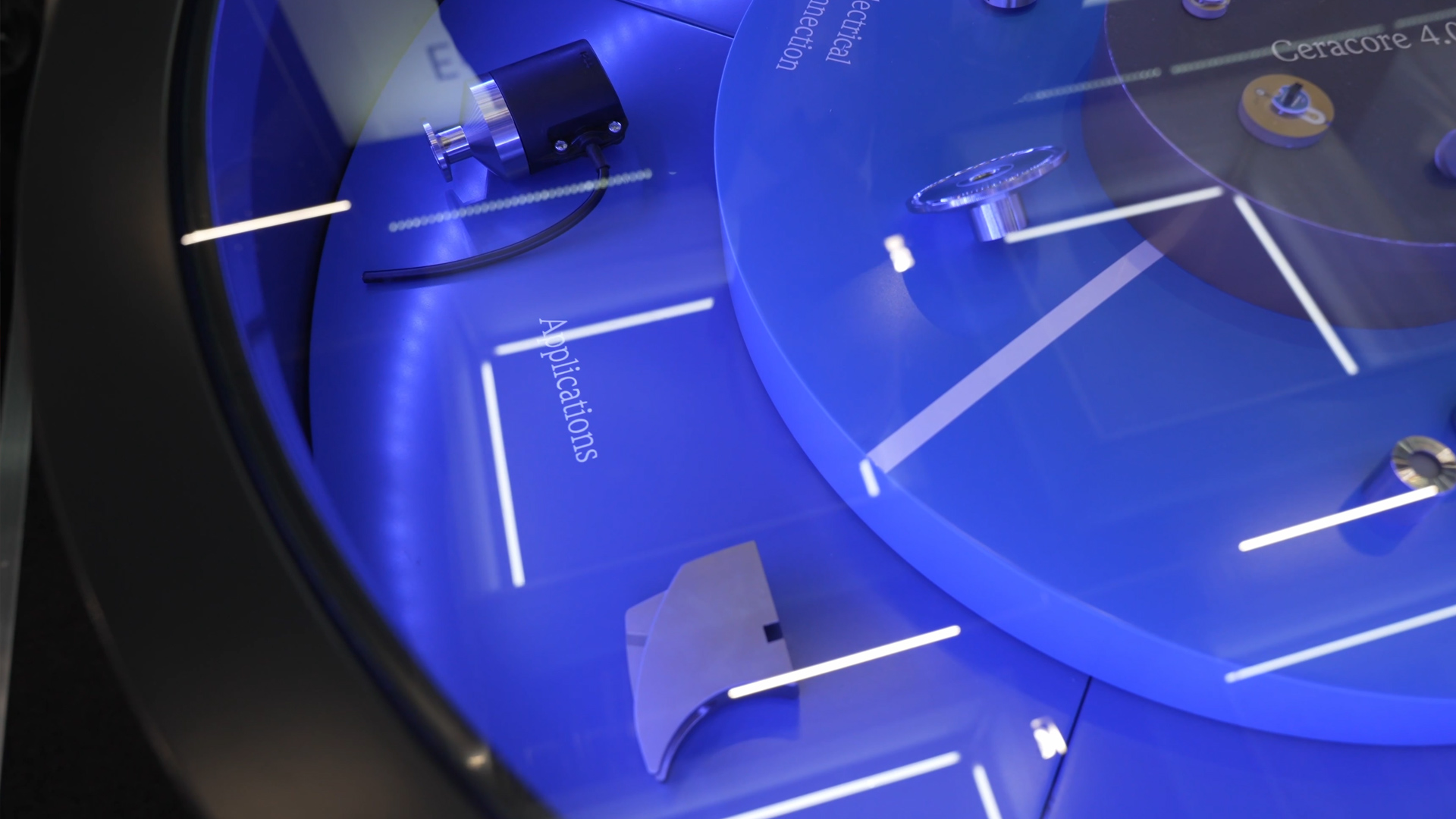

A key element of the sensor technology presented is Ceracore 4.0, a pressure measuring cell whose central component is made of high-purity ceramic. The material used, based on 99.9% aluminum oxide, is characterized by its resistance to abrasive and corrosive media.

This technology is used for both absolute and relative pressure. The sensor function is based on the plate capacitor principle: a flexible outer membrane plate is deformed by the applied pressure and moves toward a rigid base body. In the event of extreme pressure peaks, the membrane lies completely flat without breaking—a mechanical protection concept that enables overload resistance of up to 40 times the nominal pressure.

The robust design of these pressure measuring cells opens up a wide range of applications. They are particularly relevant for use in peristaltic pumps, as used in medical technology or biotechnology. Mechanical cleaning processes cause high pressure loads for short periods of time. Standard components would quickly reach their limits here. The specially developed sensor technology from Endress+Hauser offers the necessary overload protection without compromising measurement accuracy or reliability.

In addition to ceramic pressure sensors, Endress+Hauser also presents customized radar modules. These operate according to the FMCW (Frequency-Modulated Continuous Wave) principle, in which a transmitted wave is continuously modulated in order to analyze the reflected signals precisely. Such modules are used, for example, in water level measurement and contribute to flood prevention. The sensors on display are not designed as series products, but are offered as modular functional units for customized integration solutions – for example, for OEMs in environmental measurement technology or plant engineering.

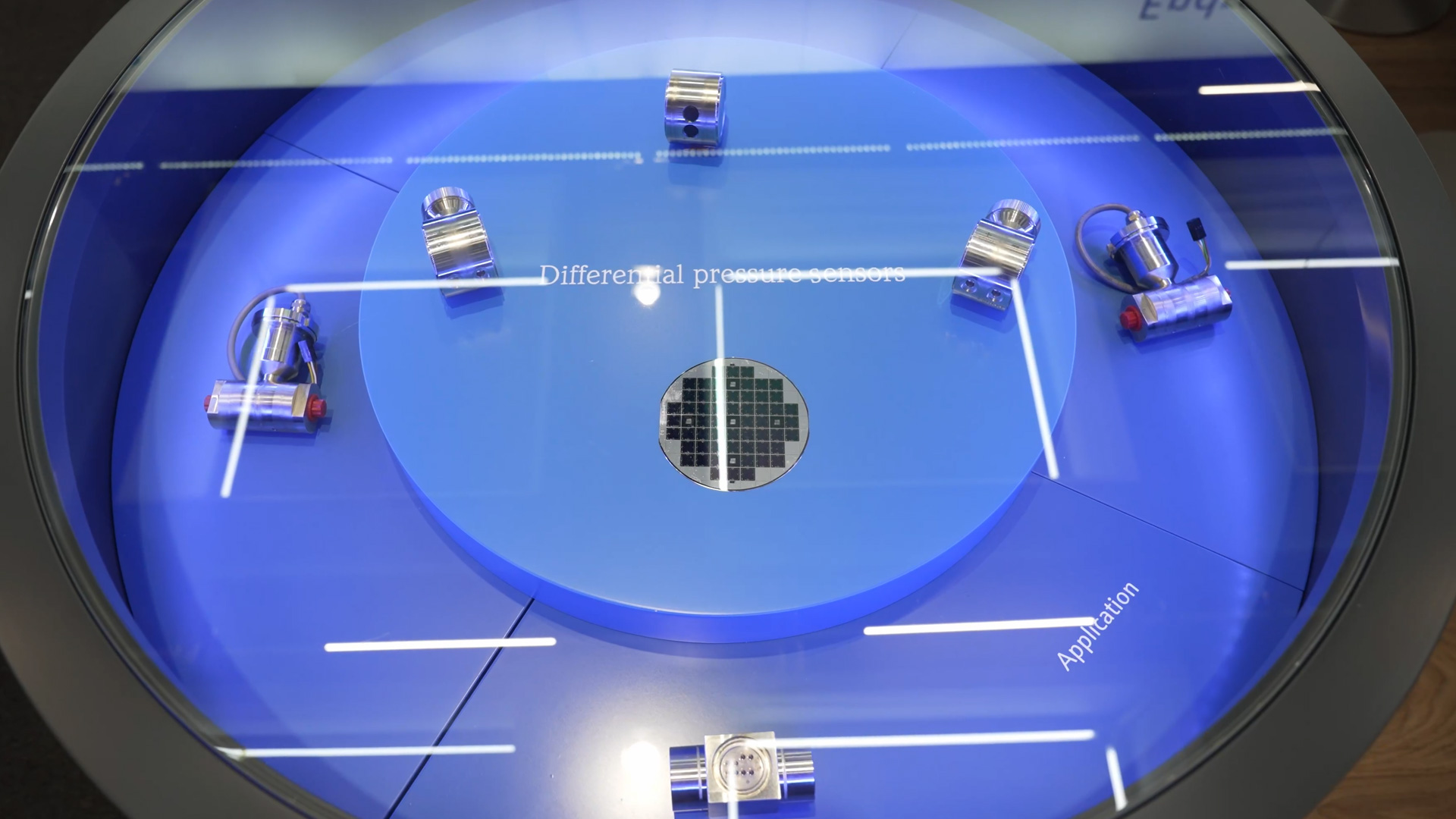

Another topic at the booth is differential pressure sensors. These are used, for example, in inventory management solutions for monitoring fill levels in tanks or silos. Endress+Hauser offers both standardized versions and application-specific modifications for this purpose. The aim is to reliably measure levels while enabling automated responses to critical conditions, for example by activating pumps or alarm systems.

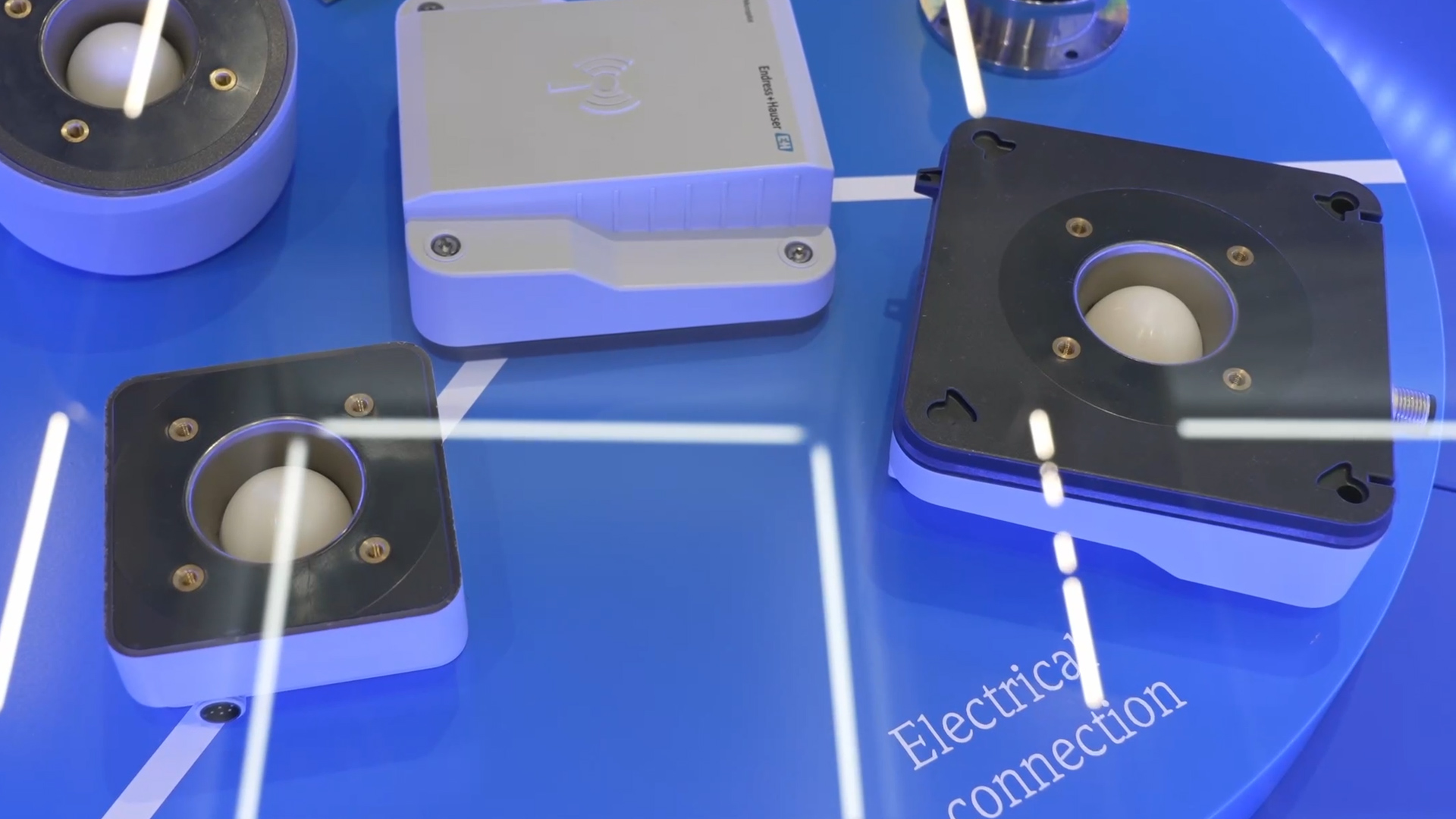

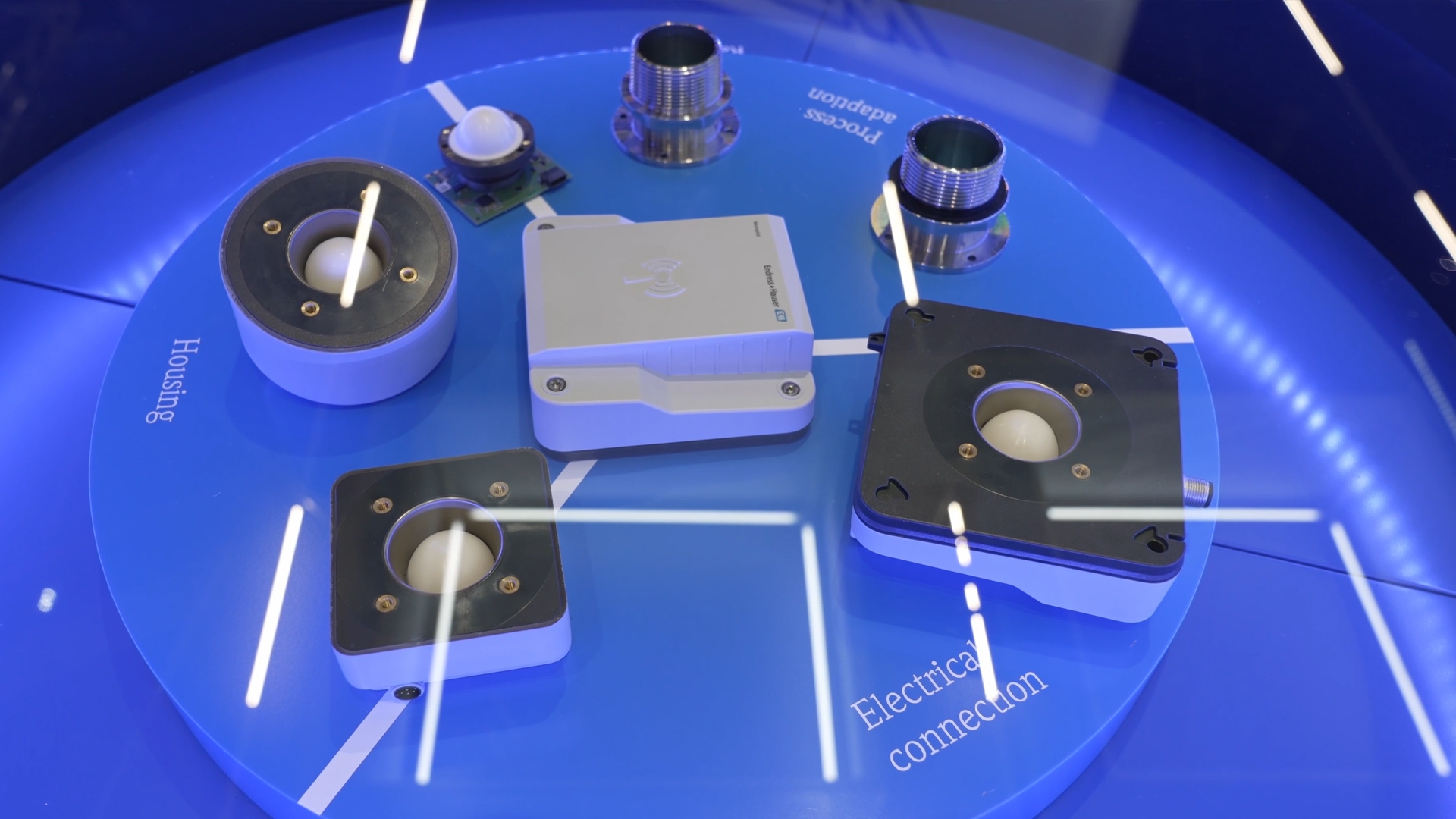

The ultrasonic flowmeter on display is a special feature that can withstand temperatures of up to 550°C. The device comes from Endress+Hauser Flow and has been nominated for the Innovation Award. Unlike conventional systems, this solution does not require a temperature decoupler.

The sensor is mounted directly on the pipe and measures the volume flow reliably and without contact – a feature that makes it particularly suitable for high-temperature processes in the chemical industry, energy technology, and the process industry.