A new acceleration sensor from STMicroelectronics opens up a wide range of possibilities for condition monitoring in industry. It measures linear acceleration in three axes and also independently detects typical movement patterns – without an external microcontroller and with extremely low power consumption. The solution presented is particularly aimed at applications where existing machines and systems need to be retrofitted without major intervention.

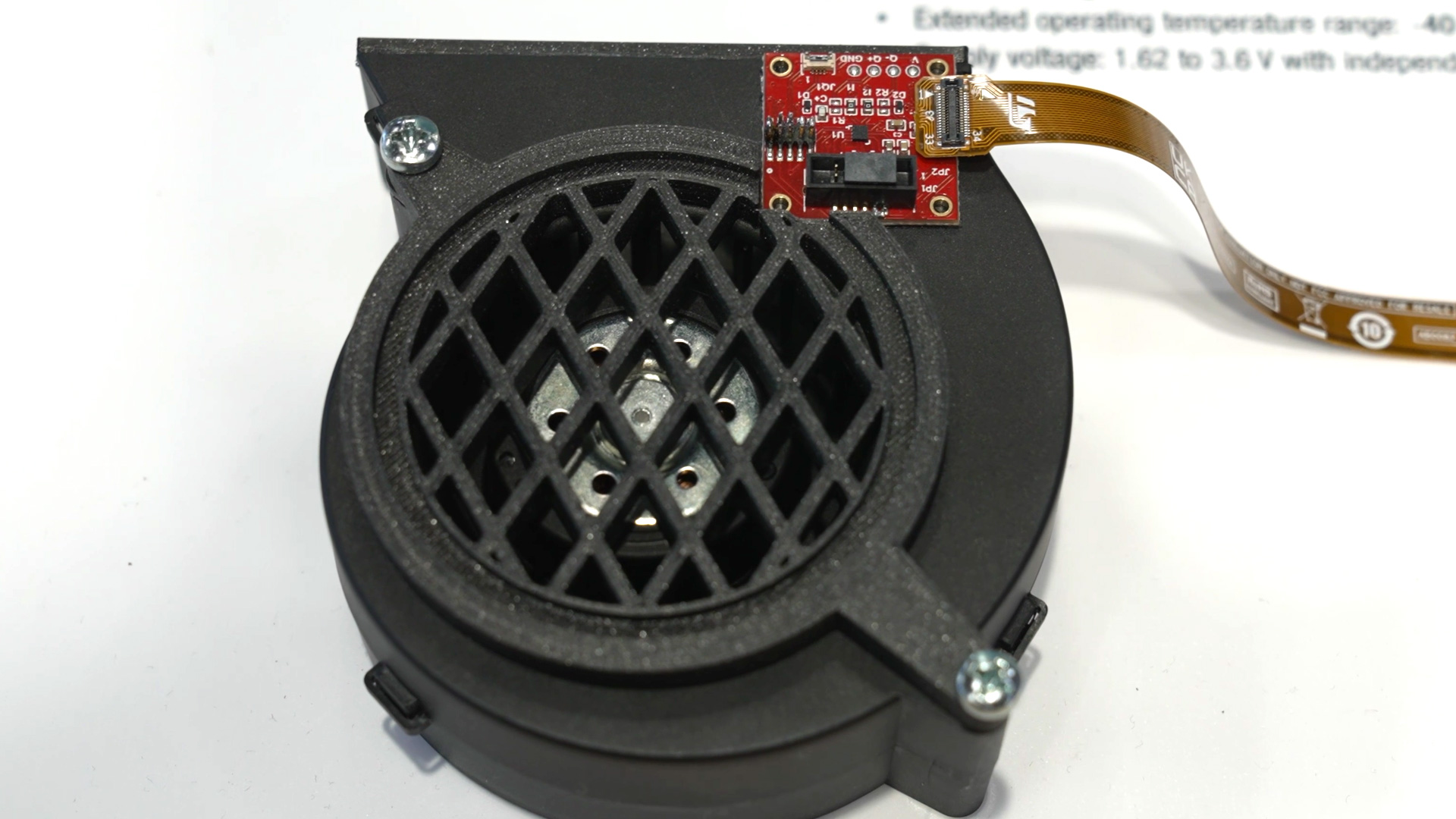

At the heart of the system is a compact 3-axis acceleration sensor that responds to linear movements in the X, Y, and Z directions. In a demonstration, the sensor was mounted on a red-painted circuit board and placed directly on a fan housing. This allows the vibrations caused by the rotation to be detected immediately. The data flows in real time to a graphical user interface, where the vibrations are visible on all three axes. This allows precise analysis of how vibrations propagate in space and what influence certain operating conditions have on the vibration behavior.

Real-time visualization provides not only quantitative but also qualitative information. Technicians can see at a glance whether the movements are within the normal range or whether there are signs of imbalance, friction, or other deviations. This level of detail is essential for industrial applications in order to prevent failures and optimize maintenance cycles based on data.

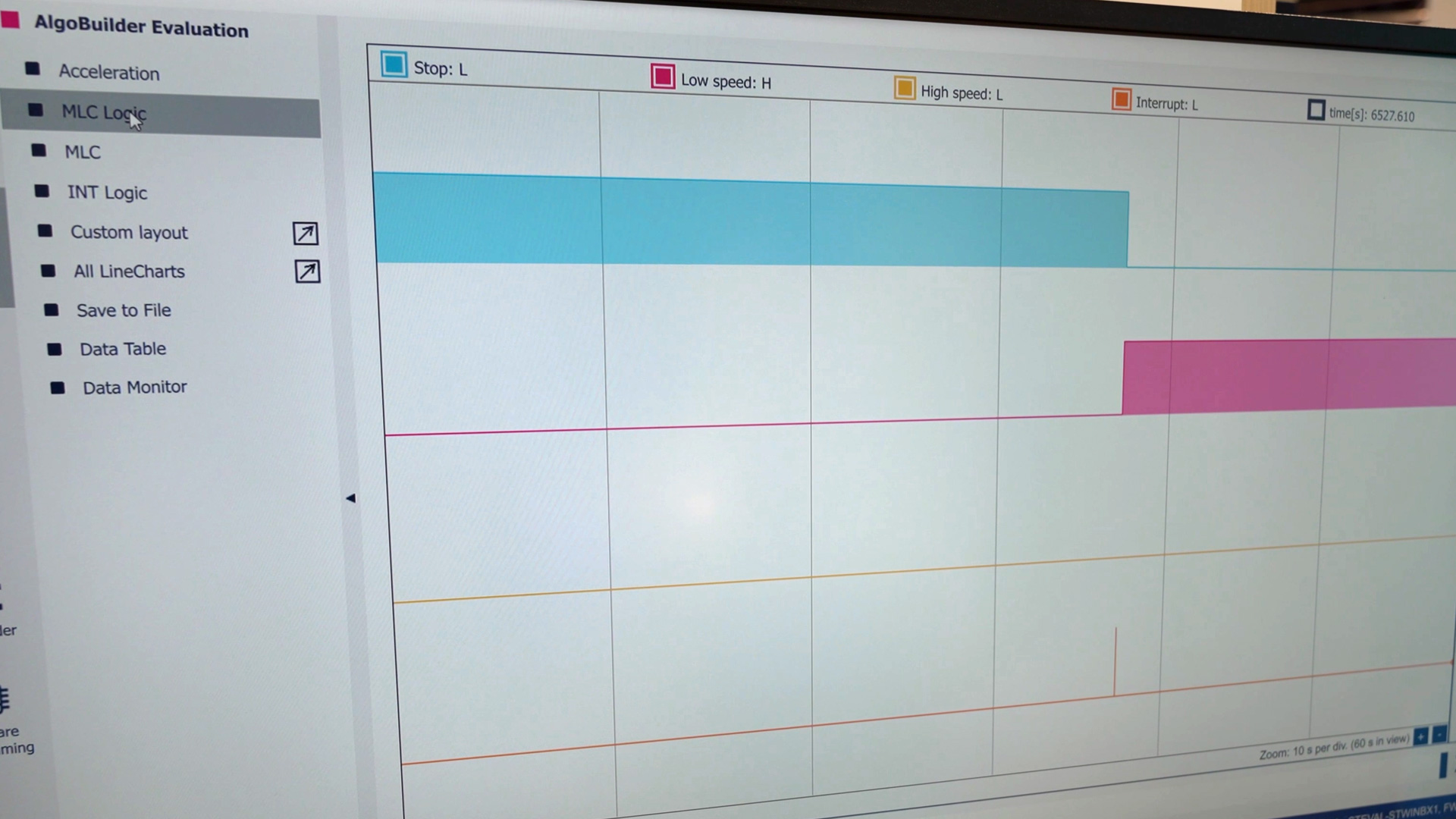

The sensor from STMicroelectronics differs from classic accelerometers in that it has an additional logic component: it continuously analyzes the measured data for characteristic motion patterns and classifies them into defined operating states. In the example system, it automatically recognizes three classes: high speed (yellow), low speed (red), and standstill (blue). The assignment is autonomous and immediate. When the fan is stopped, the status displayed changes in real time – the blue line is activated and signals a resting state.

This pattern recognition is fully integrated into the sensor. A connected microcontroller does not need to be constantly active, which significantly reduces energy consumption. The sensor only generates an interrupt signal when the status changes. This means that the entire system is only brought out of sleep mode when there is actually something to report. Monitoring with minimal energy consumption – ideal for battery-powered installations.

According to STMicroelectronics, a key area of application is in retrofit applications. Here, existing machines or systems – such as fans, pumps or motors – are retrofitted with sensors to enable additional monitoring or data analysis. Often, no continuous power supply is available. The sensor presented was designed precisely for this application: It operates in detection mode with less than 10 microamperes of current consumption. Pattern recognition increases consumption only slightly – the total requirement remains below 20 microamperes. This makes continuous operation for several years with standard batteries a realistic possibility.

An additional advantage is that no continuous computing power is required. A microcontroller merely serves as a receiver for the signals when the sensor detects a condition that requires a response – for example, when an irregularity in the drive begins. This architecture not only reduces energy consumption but also simplifies system integration.

The combination of vibration measurement and pattern analysis creates a system that is particularly suitable for implementing predictive maintenance concepts. The ability to recognize typical operating conditions makes it possible to detect deviations at an early stage. In a fan, for example, it is possible to detect the first signs of a blockage or contamination – such as unusually high vibrations at reduced speed or an irregular transition between status classes.

Appropriate warning signals can be triggered before a technical problem leads to a complete failure. The sensor registers changes caused by blockages or bearing problems and informs the microcontroller of the detected event. The result is a monitoring system that not only provides current operating data but also reacts proactively to malfunctions – and does so with minimal energy consumption.

A complete evaluation kit is available for developers and integrators. This includes the sensor board, a matching microcontroller board, and a graphical user interface for evaluation. The GUI used is freely available and allows easy visualization of the sensor data. The example application shown was also implemented with these tools – it is not only for demonstration purposes but can also be used as a template for your own projects.

Since all components are publicly available, individual applications can be implemented quickly. Evaluation of the sensor can begin immediately without the need for additional hardware or special software. This makes the system ideal for companies that are gaining initial experience with intelligent sensor technology or want to upgrade existing products with modern monitoring technology.