The technology company NanoSen has developed a sensor base material that sets new standards in robustness and precision. The conductive silicone combines piezoresistive and piezocapacitive properties and is suitable for a wide range of applications – from sensitive robotics and wearable sports analytics to heavy-duty monitoring. The scalability of its manufacture and high load capacity make the material a practical solution for modern sensor systems.

At the heart of the technology is a specially developed polymer nanocomposite, or PNC for short. This is a silicone base into which carbon-based particles have been homogeneously incorporated. The result is a continuously conductive material that responds to pressure changes with measurable changes in its conductivity. When the mat is loaded or deformed, the resistance changes – an effect that can be used for both low and very high forces. The structure remains robust: even loads of several megapascals are no challenge for the material.

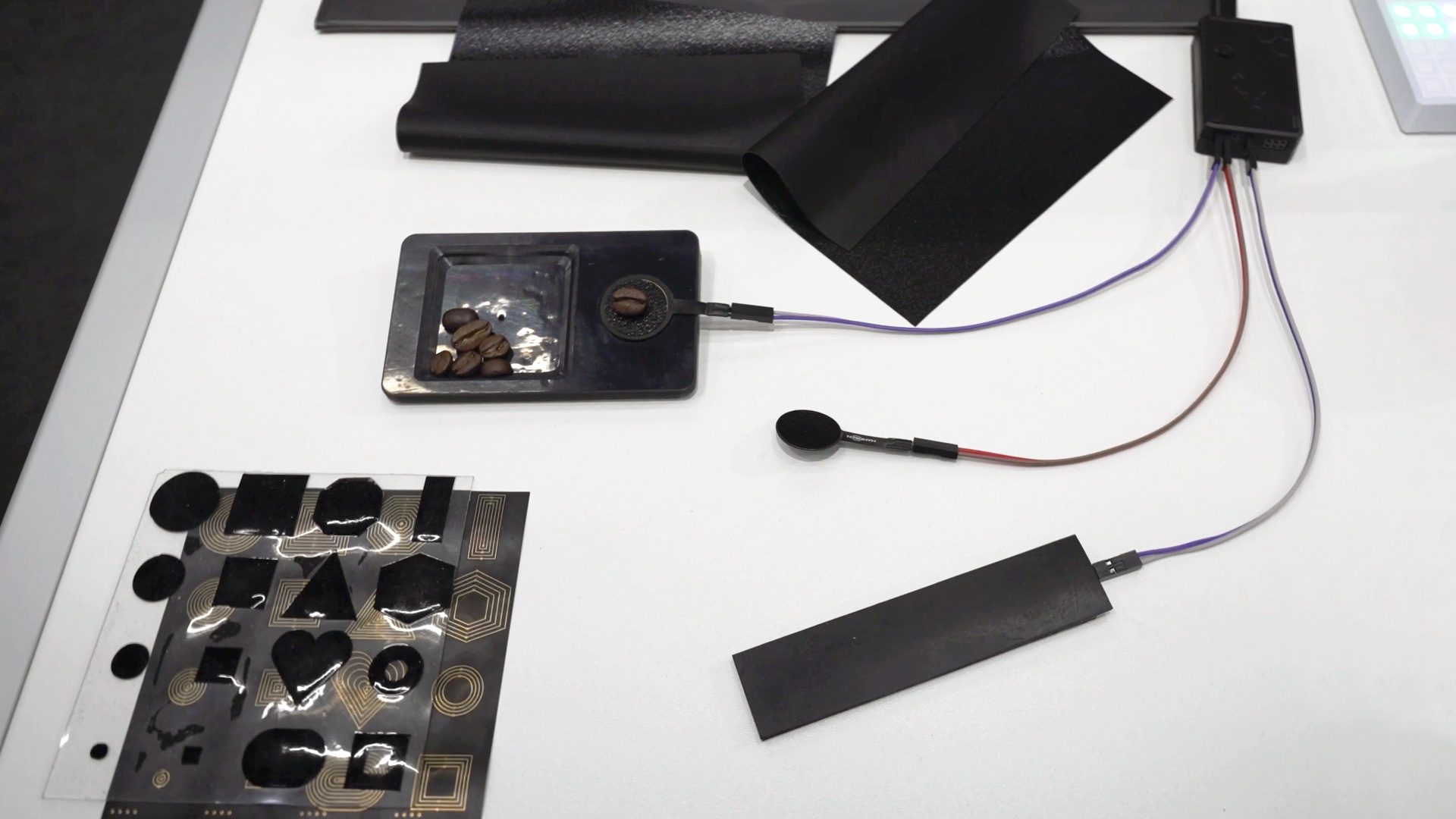

Thanks to these properties, the material is used in a wide range of industries. In robotics, for example, sensors are integrated directly into the fingertips of gripper arms. The resulting tactile surfaces enable robots to work with a high degree of sensitivity – comparable to the human sense of touch. In sports technology, a different approach is taken: here, sensors are incorporated into clothing or footwear to measure, for example, the force transmitted when pedaling a bicycle. The data helps to improve training analyses or record movement patterns in detail.

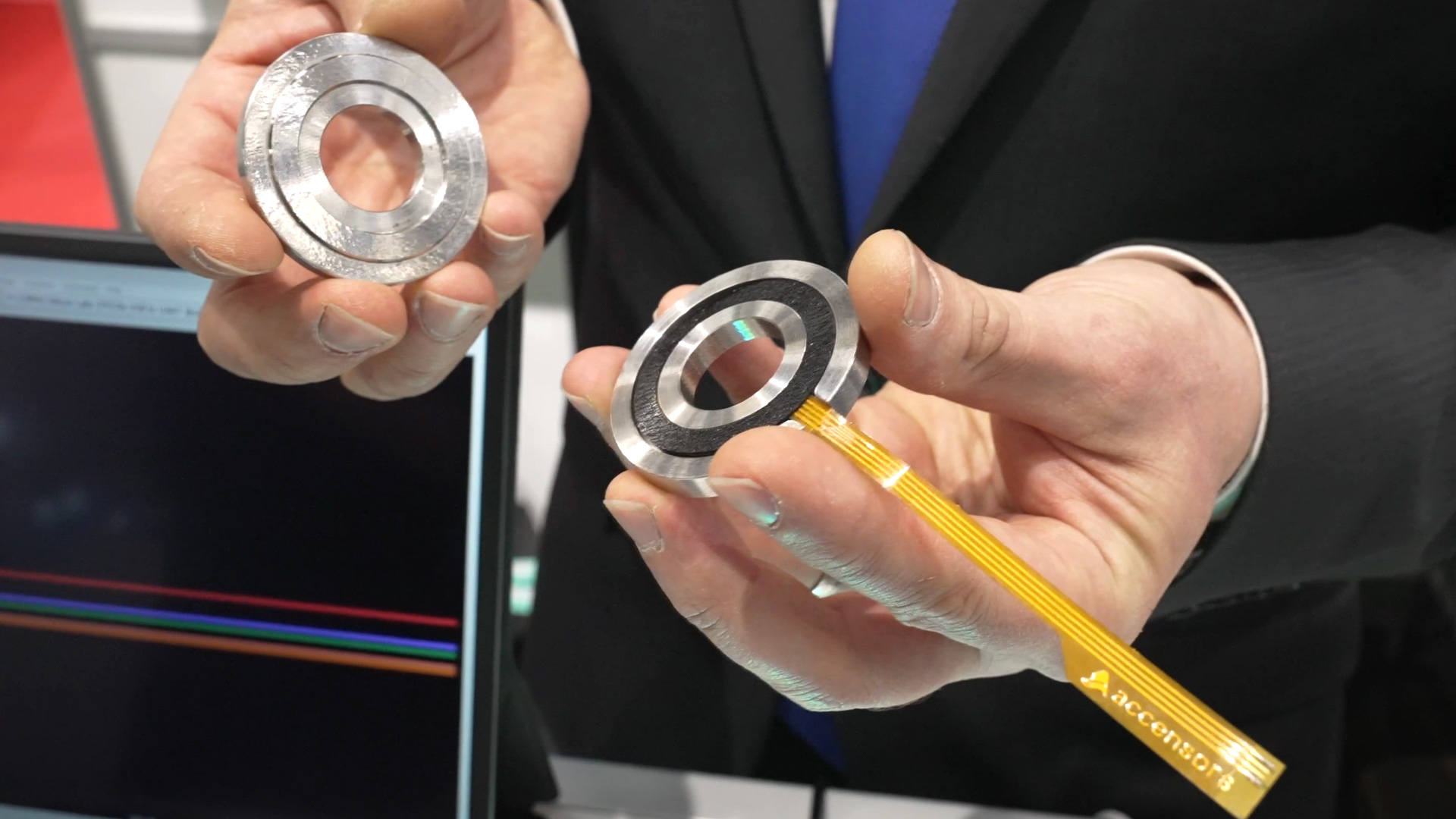

The material is also used in heavy-duty applications – encased in robust metal housings. In such designs, measurements of up to 220 kilonewtons are possible. This is the case, for example, in transport racks for rotor blades, where it is crucial that the load is evenly distributed and components are correctly supported. The sensor detects deviations, for example if a part carrier is missing or incorrectly loaded – information that is essential for safe logistics processes.

The robustness of the material has been tested in endurance tests. In one test, the mat was loaded 7.5 million times with 20 kilograms – without failure or loss of function. The tests are continuing. Even under point loads of up to 20 megapascals – equivalent to 20 kilograms per square millimeter – the material remains stable. Its durability and resistance under continuous load make it a reliable component for industrial applications with high demands on material fatigue and resistance.

Ten years of research at Chemnitz University of Technology went into the development of this material. The company, a spin-off from the university, has not only brought the material to market maturity, but also enabled production on an industrial scale. Today, it is possible to produce large, homogeneous mats in quantities that allow for economical integration into series products. Unlike many experimental solutions, a well-thought-out process has been developed here for the production of a functional material that can be used immediately in a variety of industries.

The company sees itself not only as a supplier, but also as a development partner. It is looking for manufacturers who can integrate the material into existing or new sensor concepts. Whether as a system supplier for automation technology, in mechanical engineering or in medical technology – a modular system allows individual requirements to be met. The material basis can be adapted, sensor architectures configured and applications developed jointly.

The PNC material is based on a consistent principle: complete conductivity across the entire surface without additional coating, combined with high mechanical resilience and reproducibility. Every intersection, every section of the mat can be used as an independent sensor – always with the same properties. A property that took ten years of research to implement in this form.