R-Cycle data standard – networking packaging information across industries

by F. Zuber - 2025-10-17R-Cycle is an industry initiative that develops digital product passports for packaging. It is based on a data standard agreed with GS1 that enables packaging information to be transferred securely, uniformly, and across company boundaries.

This standardized data collection will become indispensable in the future, as manufacturers will be required to provide detailed information on material composition, recyclability, and recycled content in accordance with the new EU Packaging and Packaging Waste Regulation (PPWR). R-Cycle offers a central platform where this information can be collected, structured, and shared. Whether it's a bottle, film, or cup, all components of packaging can be recorded, merged, and displayed transparently in the system.

Aggregate and evaluate packaging data with R-Cycle

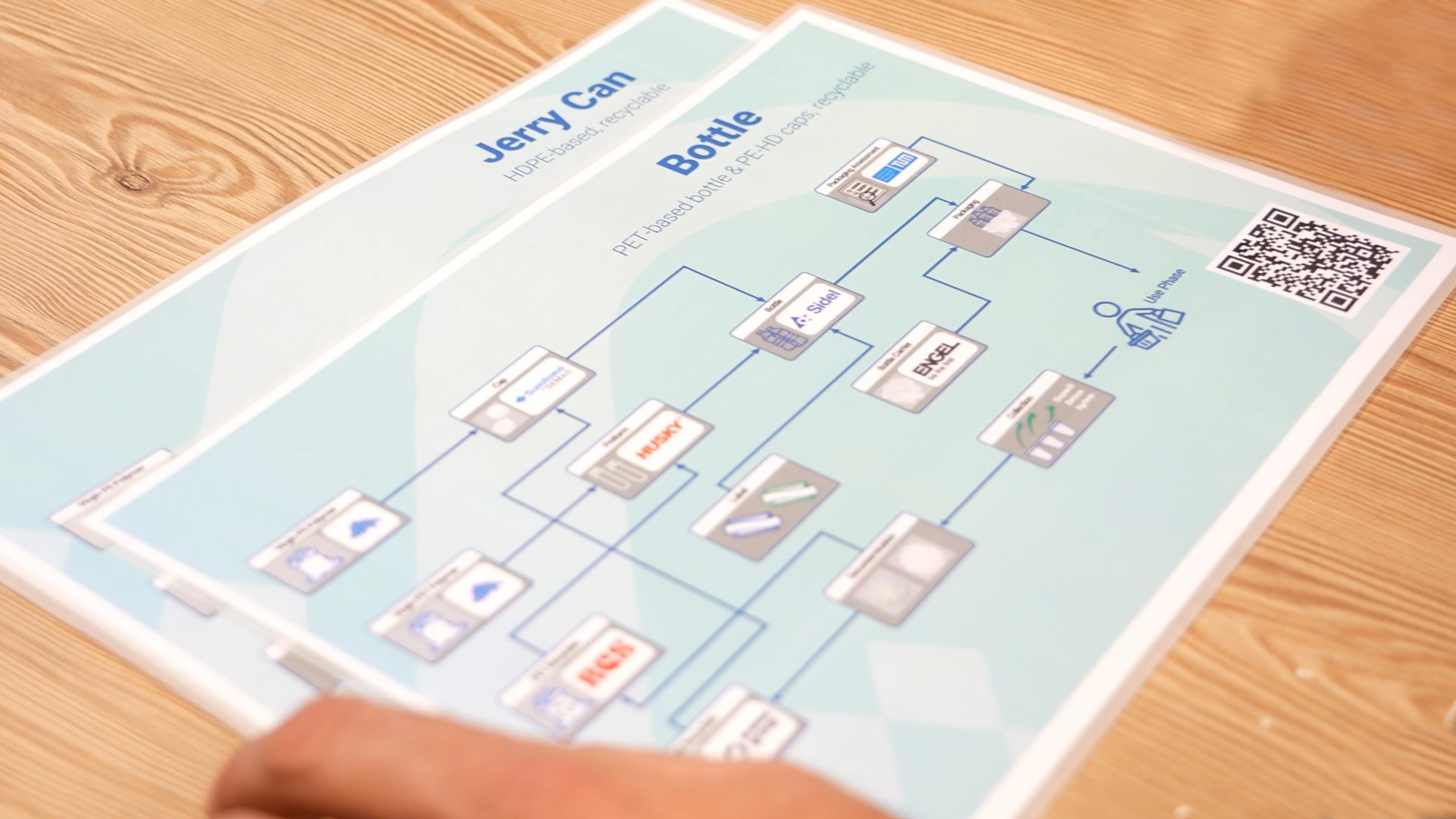

Packaging consists of several components: a bottle, a label, a cap – often manufactured by different suppliers. R-Cycle makes it possible to combine all this individual information into a complete data set. The tool automatically aggregates the data and uses it to create a complete digital product passport. Manufacturers and distributors can thus track at any time which materials have been processed – whether it is polypropylene or PET, what proportion of EVOH or dyes is contained, and how high the recycled content from post-consumer material is. This transparency is the basis for assessing recyclability and for the legally required evidence to authorities and business partners.

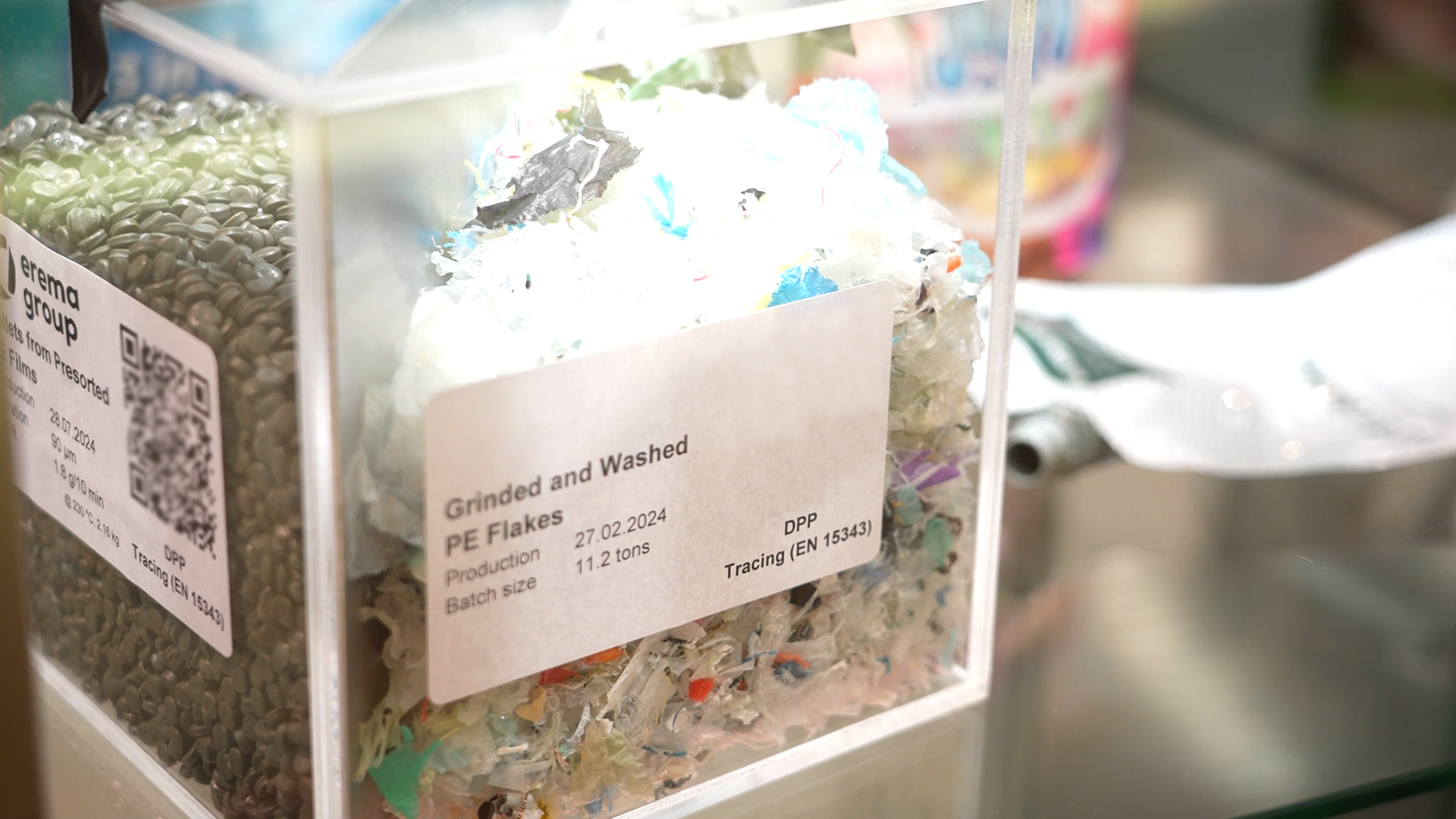

R-Cycle Traceability – Traceability back to the recycled material

A key feature of R-Cycle is its seamless traceability. The digital data flow allows the use of recycled materials to be precisely documented – from the origin of the material to the finished product. This proves that post-consumer recycled material is actually contained in the packaging and in what quantity. The so-called packaging tree maps the path of the material: for example, a bottle is made from recycled material, and its data record is combined with information about the label and cap. The distributor can then generate a complete report on the entire packaging – important evidence in the context of EU regulations.

Data flexibility: product, batch, and series level

R-Cycle's data concept has a modular structure. It allows packaging information to be recorded at product level, batch-based, or even serially – for example, in the case of reusable packaging. Each packaging unit can be assigned a unique GS1 ID. This also makes reuse digitally traceable: for a canister or tray, it is possible to document how often it has already been in circulation, which products it has been used for, and whether it is still usable. R-Cycle thus enables not only recycling but also reuse management on an industrial scale.

R-Cycle as a tool for PPWR-compliant companies

Starting in the coming years, the EU will require clear evidence of the material composition, recycled content, and recyclability of packaging. While large manufacturers often operate their own databases, R-Cycle also offers small and medium-sized businesses access to a standardized solution. The tool thus closes a crucial gap in the market: suppliers, label manufacturers, or lid producers can store their data directly in the system. The final packaging manufacturer compiles this information and, with just a few clicks, creates a report that meets all legal requirements. This makes R-Cycle a practical tool that brings digital transparency to the supply chain – and at the same time creates the basis for a functioning circular economy.

R-Cycle – Digital product passport for packaging and the circular economy

R-Cycle is making a decisive contribution to the transformation of the packaging industry. The digital exchange of material data not only facilitates compliance with regulations, but also enables innovation: automated sorting, material optimization, and ecological design benefit from the information gained. With its open data standard, R-Cycle creates the basis for an internationally compatible solution that will connect all players in the packaging value chain in the future – from raw material suppliers to recycling companies.